Wheel rim drive-type omnidirectional wheel capable of measuring feedback by using inductance angle displacement

A displacement measurement and wheel drive technology, applied in the field of omnidirectional wheels, can solve the problems of high cost, inaccurate angular displacement measurement, complex structure of omnidirectional wheel steering mechanism, etc., and achieve the effect of simple and compact construction and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

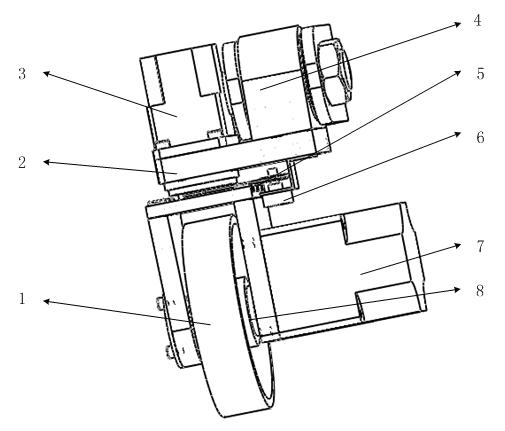

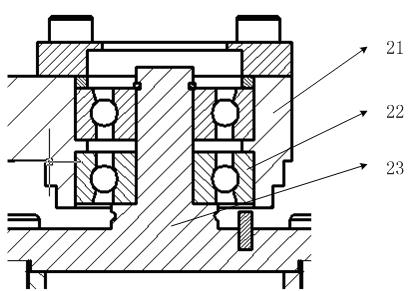

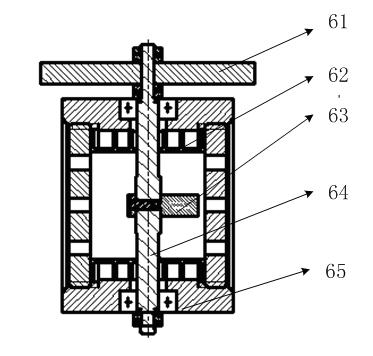

[0014] Such as figure 1 , figure 2 with image 3 As shown, the present invention includes a wheel shaft 8, a wheel 1 sleeved on the wheel shaft 8, a reversing mechanism 2 connected to the wheel shaft 8, a rudder motor 3 connected to the reversing mechanism 2, positioned on the side of the wheel 1 and connected to the reversing mechanism. The inductive angular displacement sensor 6 connected to the mechanism 2; the inductive angular displacement sensor 6 includes a casing 65, a sensor shaft 64 running through the two ends of the casing 65, a coil located in the casing 65, a skeleton 62 and a magnetic core 63; the magnetic core 63 is connected to the sensor shaft 64 , the coil and the skeleton 62 are sleeved in the shell, the coil and the skeleton 62 include two main coils and two secondary coils, the outline of the magnetic core 63 is composed of two symmetrical Archimede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com