Electronic gear shifting mechanism of electric automobile

A technology for electronic gear shifting and electric vehicles, which is applied in the direction of mechanical equipment, transmission control, and components with teeth, etc. It can solve the problems of complex structure and unsuitability for electric vehicles, and achieve simple structure, reliable performance, and shifting feeling clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

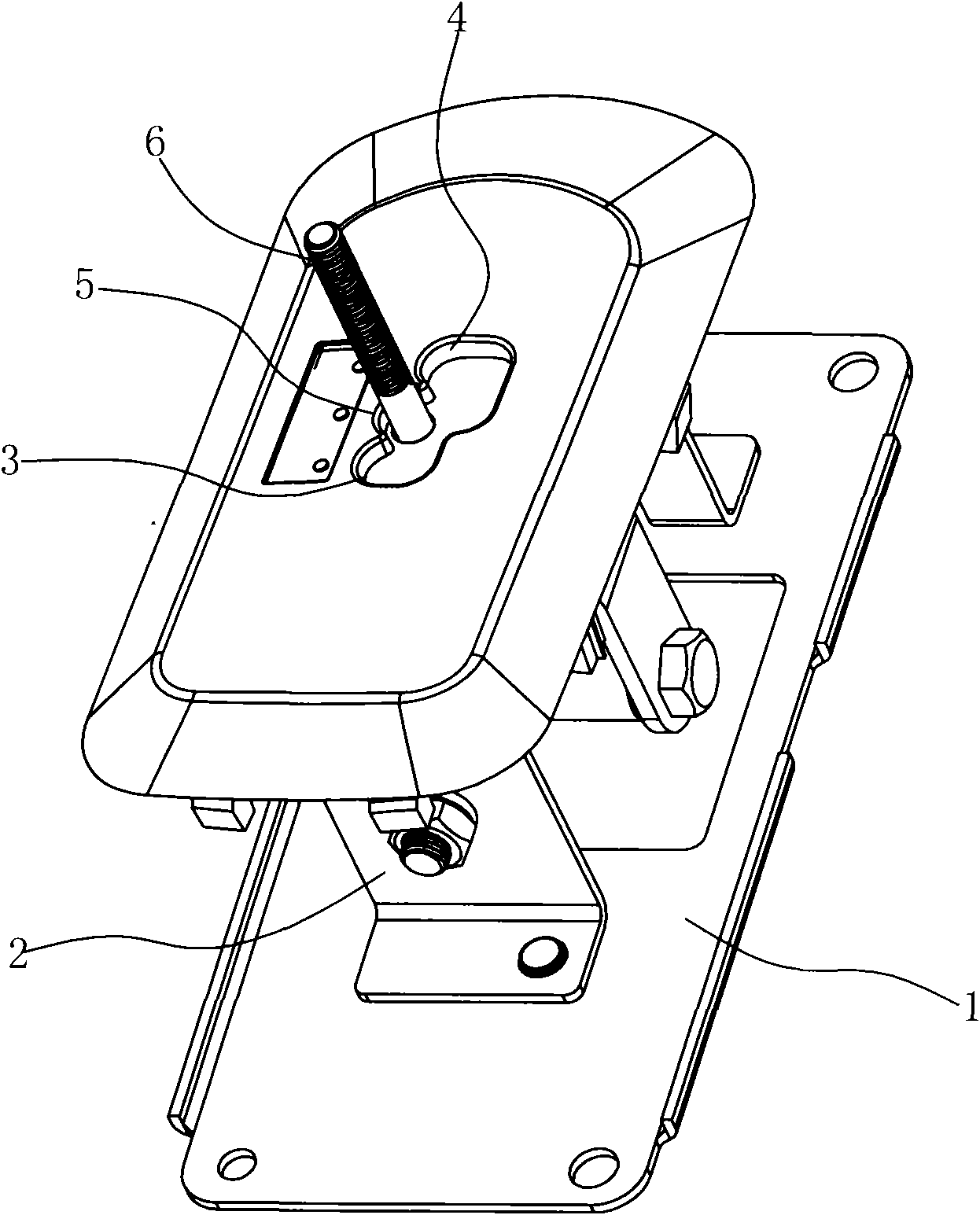

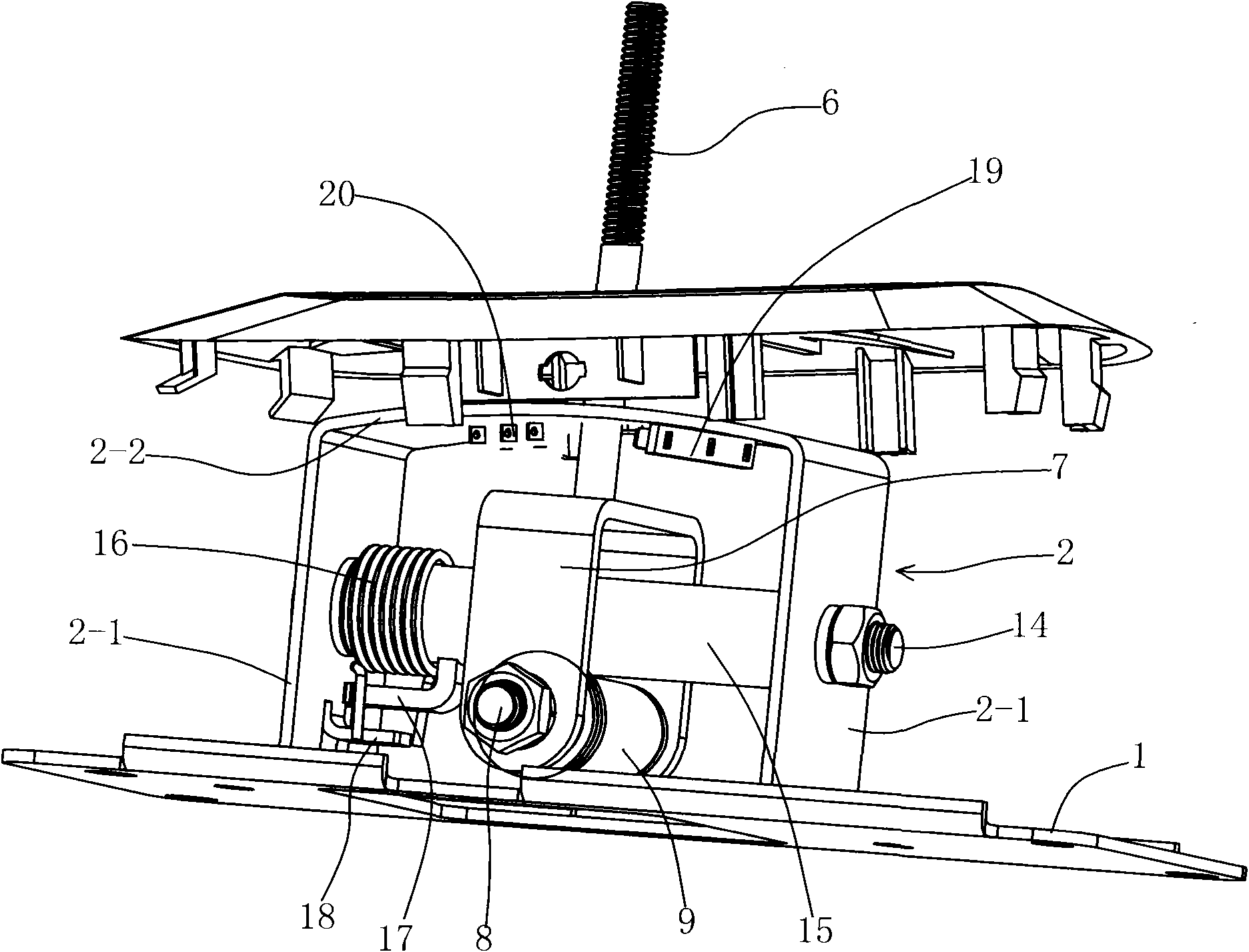

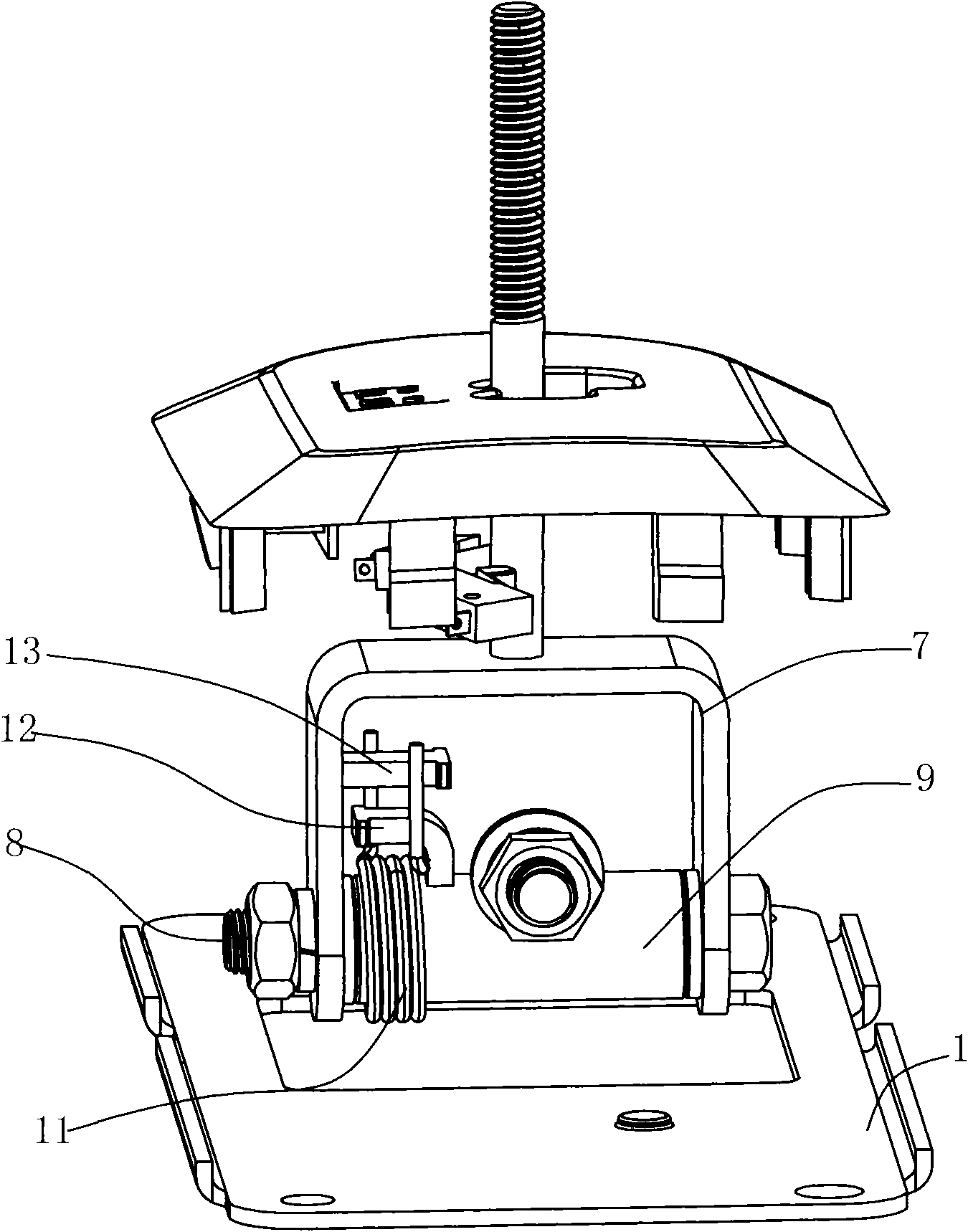

[0020] Embodiment 1: as figure 1 , figure 2 with image 3 As shown, the electric vehicle electronic shifting mechanism includes a frame, and the frame is composed of a base plate 1 and an arch bracket 2 fixed to the base plate 1. 1 The top 2-2 between the upper ends, the top 2-2 of the arch bracket 2 forms a forward gear hole 3 and a reverse gear hole 4 and a gap between the forward gear hole 3 and the reverse gear hole 4 The neutral gear hole 5, the forward gear hole is positioned at the left rear side of the neutral gear hole, and the reverse gear hole is positioned at the right front side of the neutral gear hole. The upper end of the shift lever 6 passes through the top 2-2 of the arch bracket 2 and can be switched in the neutral gear hole 5, the forward gear hole 3 and the reverse gear hole 4; the lower end of the shift lever 6 is fixed There is an arched connecting seat 7, and the transverse shaft 8 is fixed between the two vertical parts of the arched connecting sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com