Method and device for detecting oil mixing interface in sequential oil transportation

The technology of a detection device and detection method is applied in the direction of detecting fluid flow, gas/liquid distribution and storage, and volume/mass flow generated by mechanical effects by measuring differential pressure, which can solve the problems of reducing the commodity value of oil products and achieve cost reduction. Low, accurate pressure difference signal acquisition, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

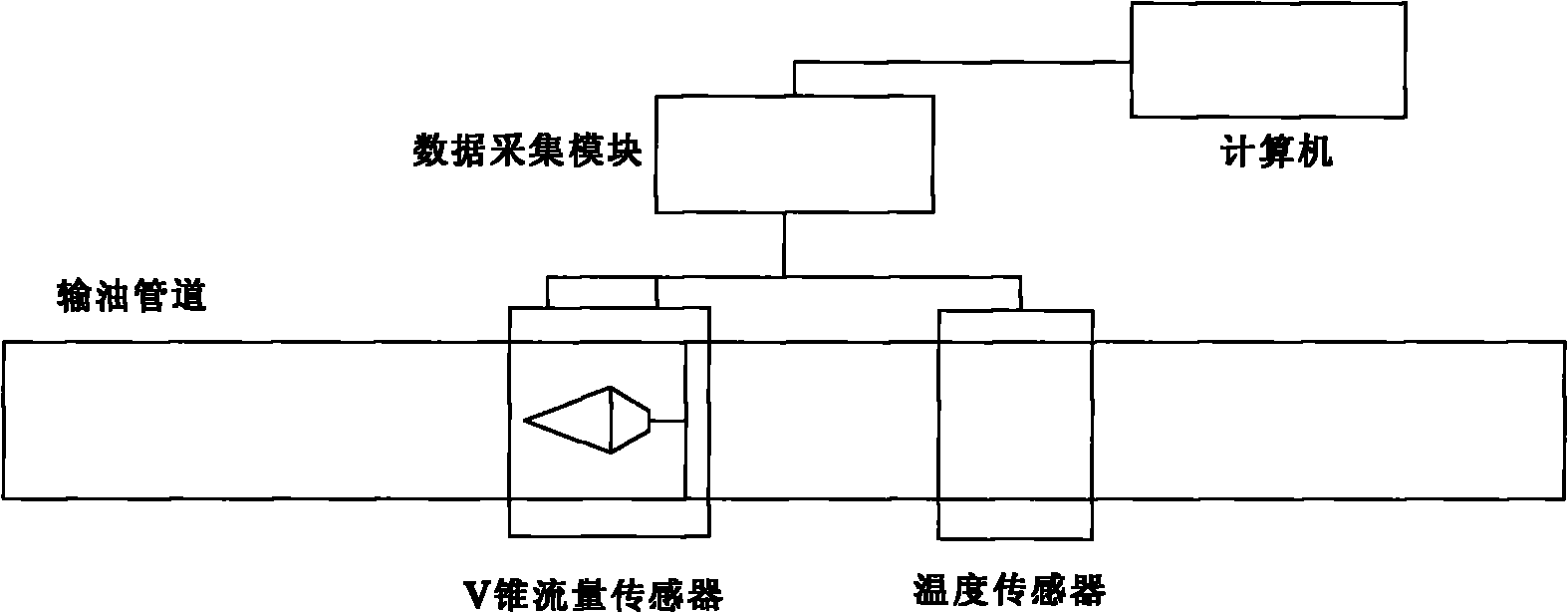

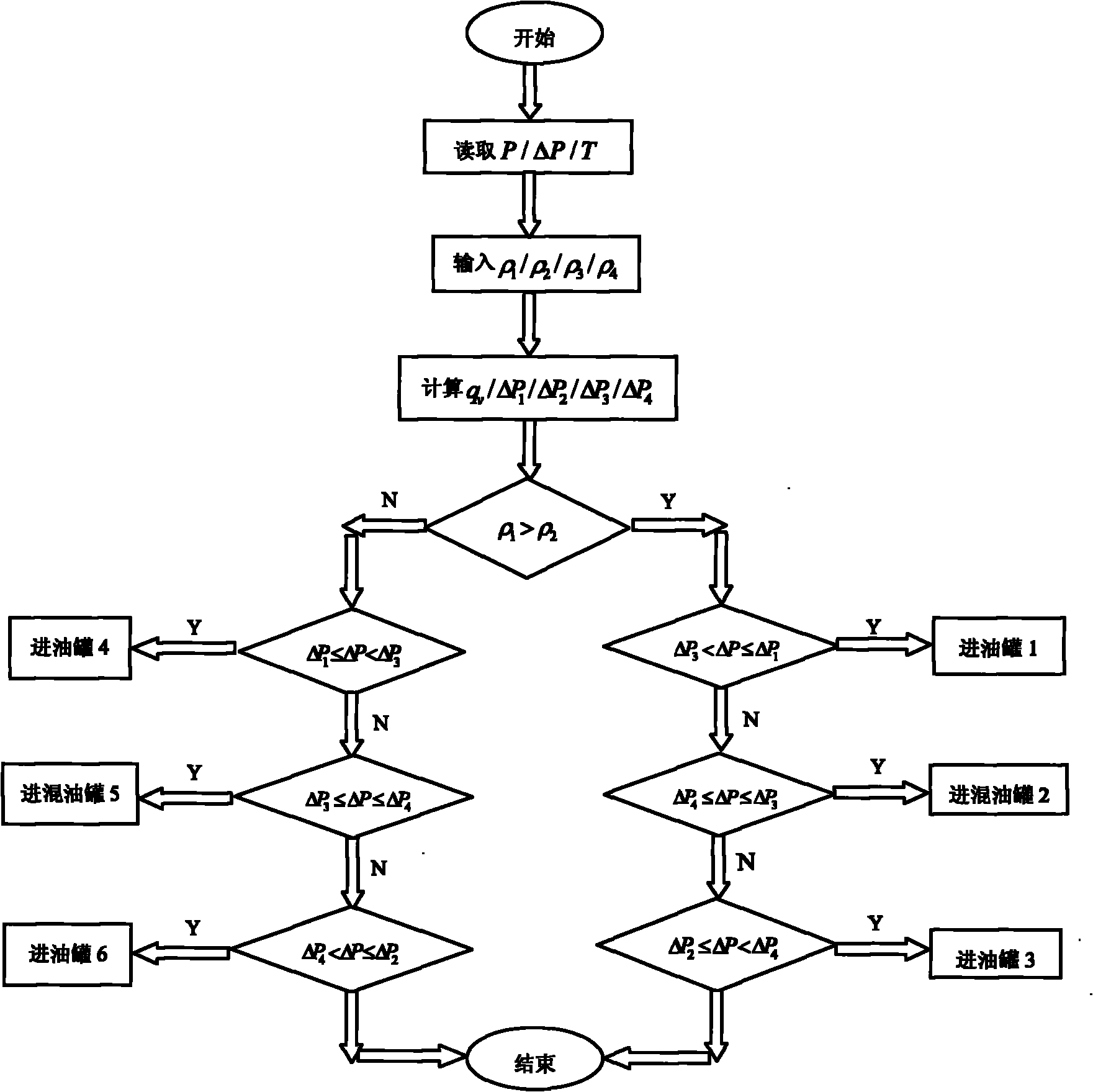

[0019] The device of the invention has an oil pipeline, on which there are a V-cone flow sensor and a temperature sensor. The signal output of the V-cone flow sensor and the temperature sensor is connected to a data acquisition module, and the data acquisition module is connected to a computer through a data cable.

[0020] After the oil enters the oil pipeline, it flows through the V-cone flow sensor and temperature sensor. The pressure, pressure difference signal and temperature signal are sent to the data acquisition module, and the data is collected and processed and then sent to the computer. The respective parameters of the oil mixing section.

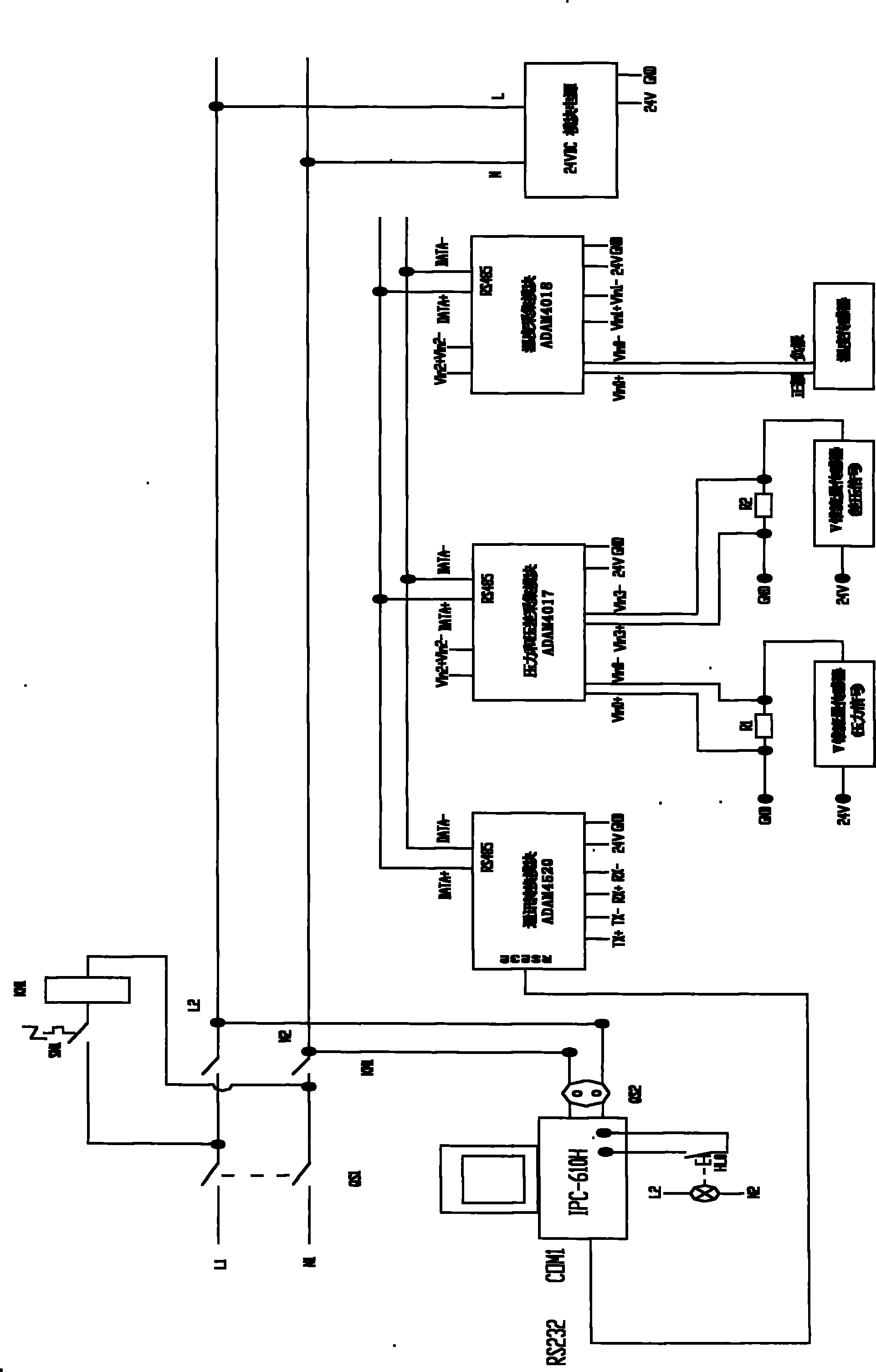

[0021] The pressure signal and pressure difference signal of the V cone flow sensor are respectively connected to the Vin0+, Vin0- and Vin3+ and Vin3- terminals of the pressure and pressure difference acquisition module; the output signal of the temperature sensor is connected to the temperature acquisition module Vin0+ and Vin0- termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com