Camshaft adjuster

A technology of camshaft adjuster and crankshaft drive, which is applied in the direction of machines/engines, valve devices, mechanical equipment, etc., and can solve the problems of increased leakage loss and increased clearance of camshaft adjusters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

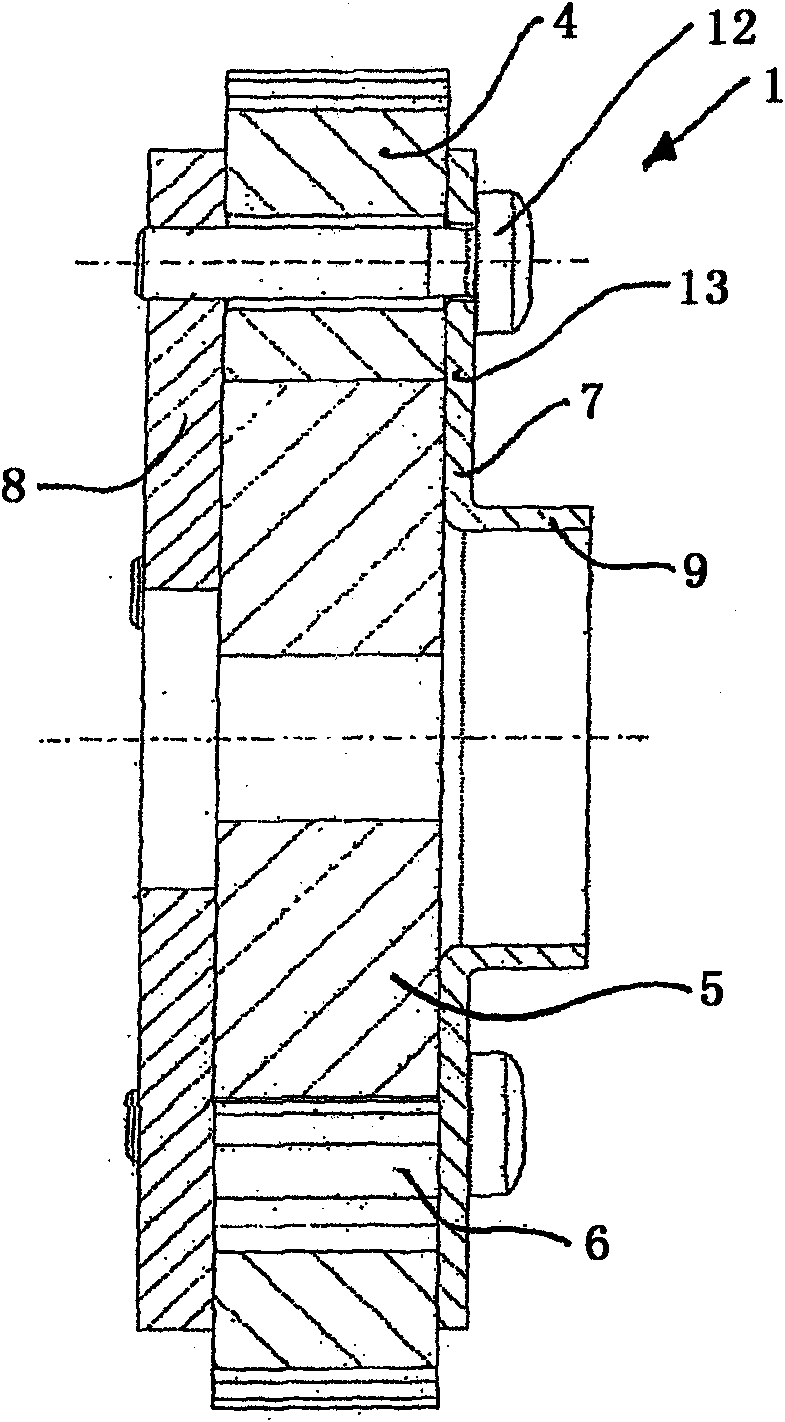

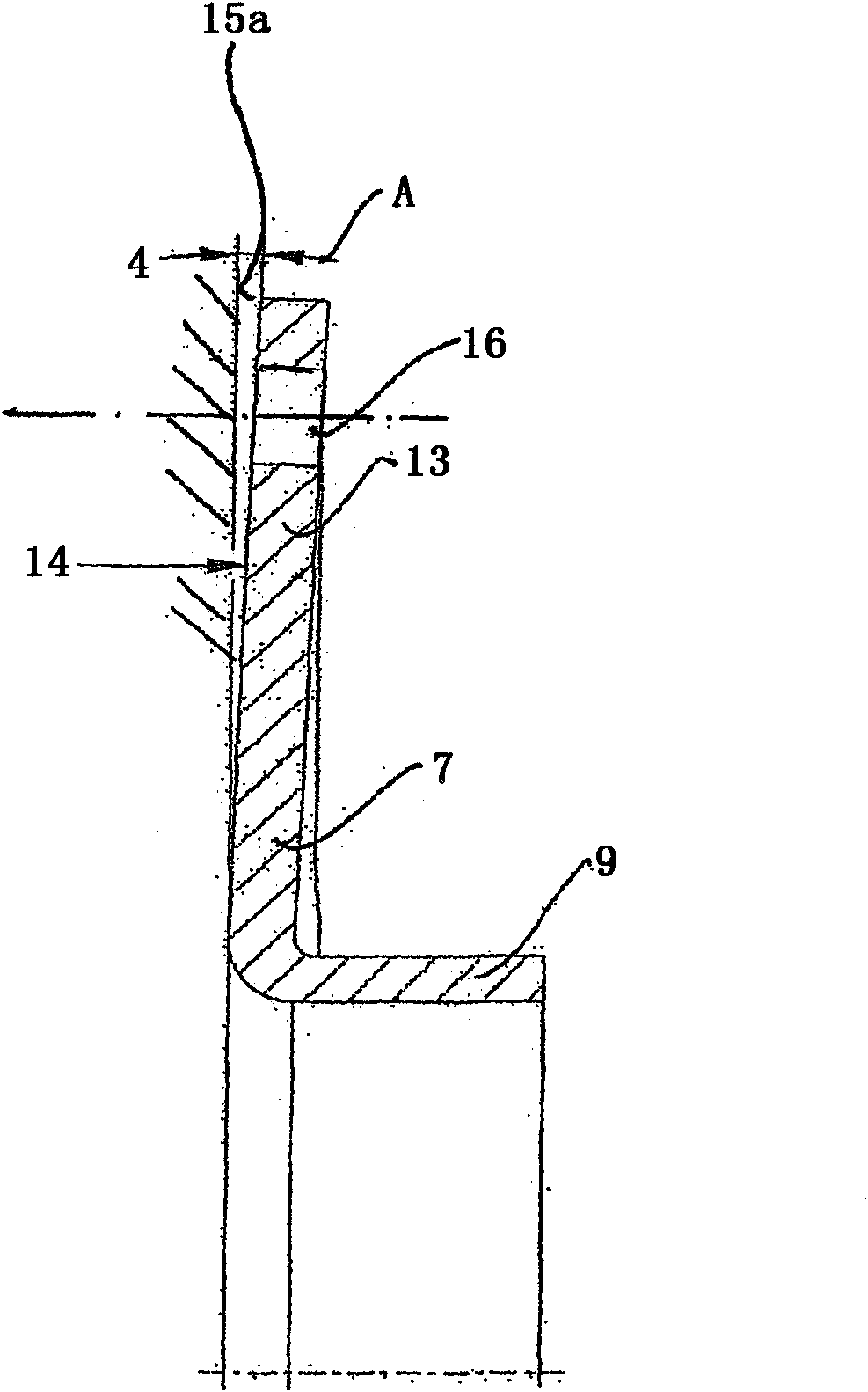

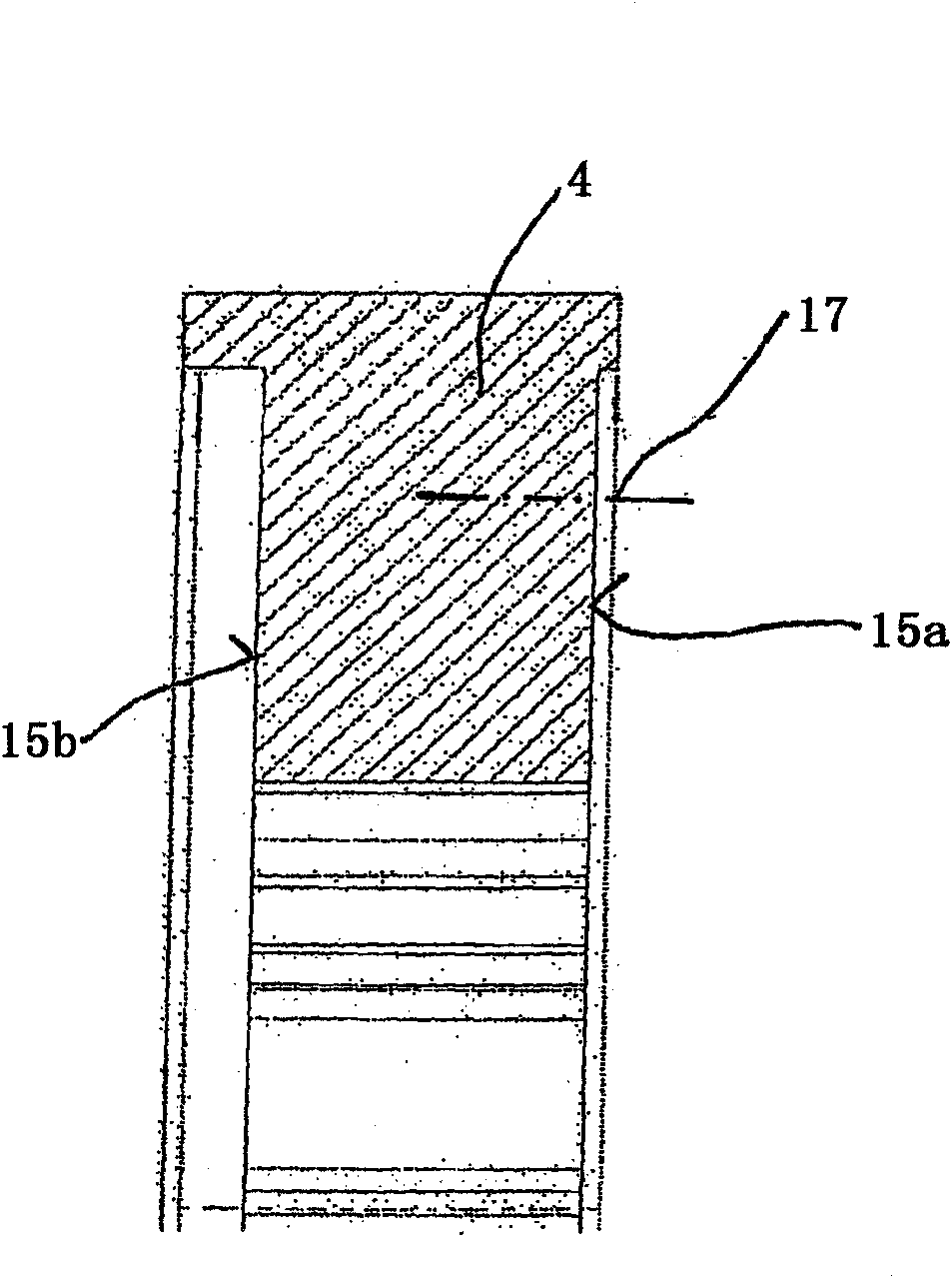

[0014] from figure 1 A camshaft adjuster 1 can be seen in the figure, which has a stator 4 which is driven by a crankshaft (not shown) of the internal combustion engine and a rotor 5 which is connected in a rotationally fixed manner to the camshaft. A plurality of working chambers 6 are arranged between the stator 4 and the rotor 5 and are delimited laterally by sealing covers 7 and sealing washers 8 . The working chamber 6 is formed by radially inwardly protruding projections of the stator 4 which are supported on the radial inner diameter of the rotor 5 . The working chamber 6 is divided into two working chambers 6 , for example by vanes assigned to the rotor 5 , to which pressure medium can be applied, so that the relative rotational position of the rotor 5 relative to the stator 4 can be changed and thus also the The relative rotational position of the camshaft relative to the crankshaft. The sealing cover 7 is firmly connected to the stator 4 by means of a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com