Clamping device of casting mold

A clamping device and casting mold technology, applied in the field of casting mold processing, can solve the problems of irregular surface shape, inability to adjust the clamping mechanism, and inability to change the clamping angle of the casting mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

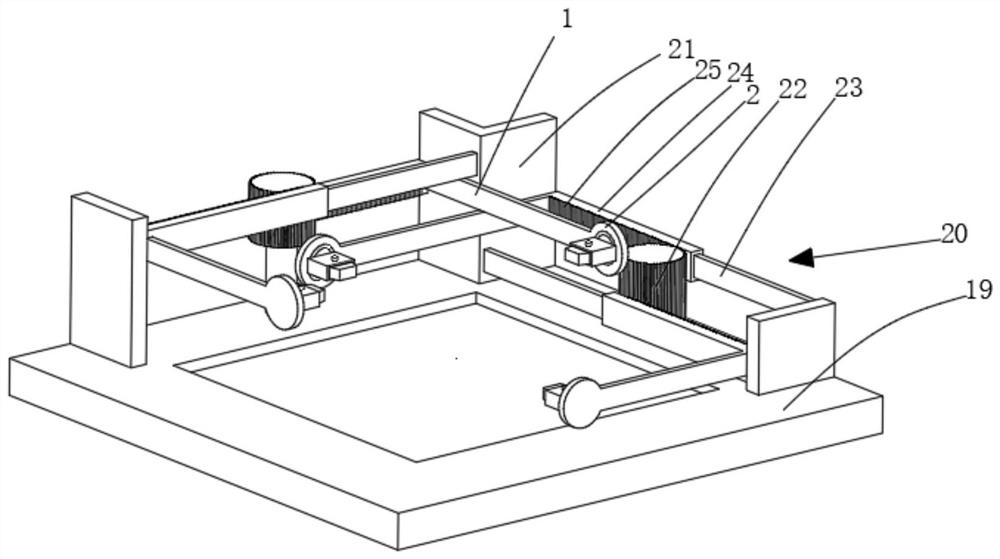

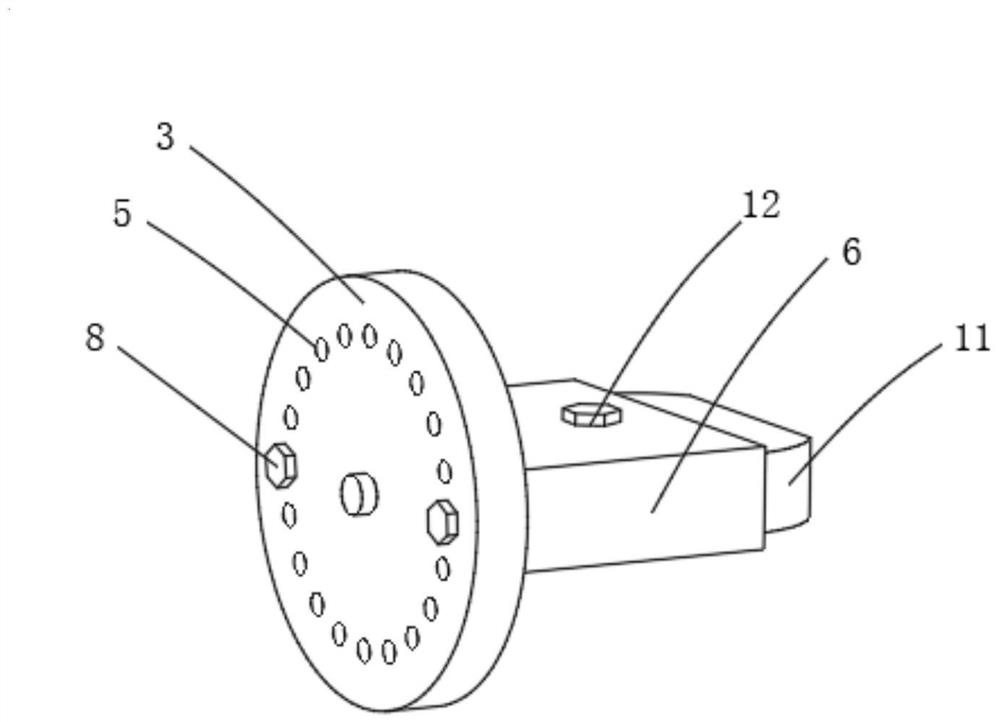

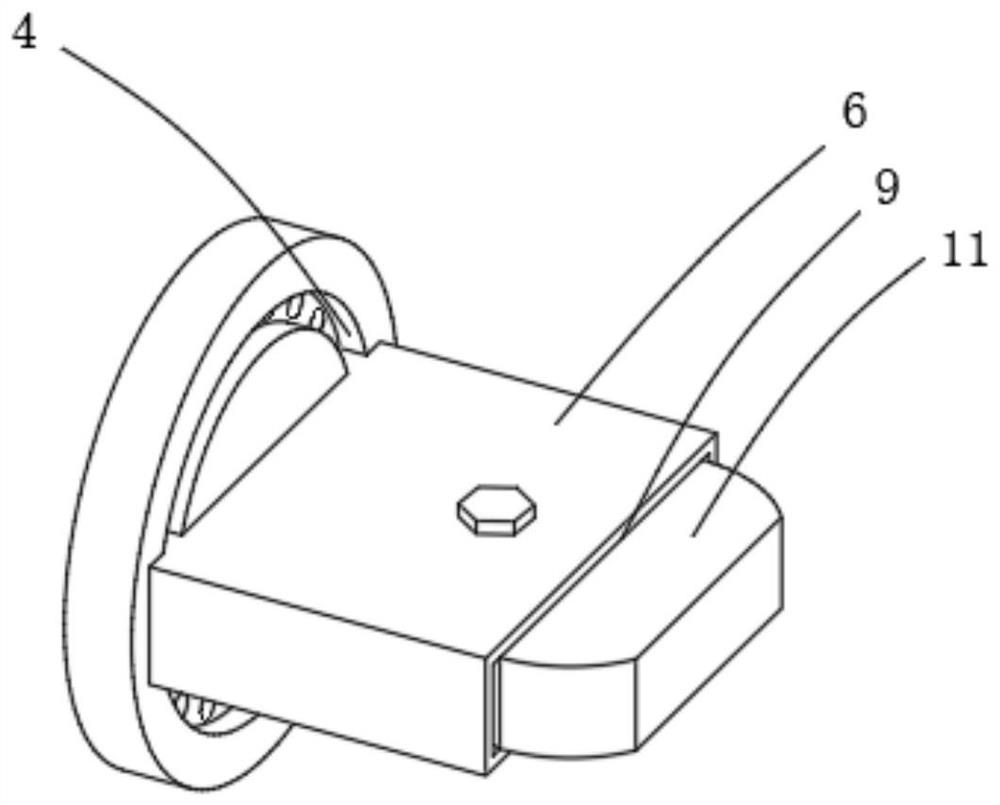

[0022] Embodiment: a kind of clamping device of casting mold, as attached figure 1 As shown, the base 19 is included, the middle part of the base 19 is provided with a clamping groove, the base 19 is provided with a transmission mechanism 20, and the transmission mechanism 20 includes two pairs of limiting plates 21, and the two pairs of limiting plates 21 are respectively adjacent to the adjacent two sides of the base 19. , and the positions of two pairs of limiting plates 21 on the base 19 are set vertically; the base 19 between each pair of limiting plates 21 is provided with a driving gear 22, and the driving gear 22 is connected with the motor, which can carry out forward rotation and reverse rotation , two driving gears 22 are arranged up and down, the upper surface of the lower driving gear 22 is lower than the upper surface of the higher driving gear 22; two guide rails 23 are arranged between the corresponding limiting plates 21, two The guide rails 23 are set up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com