Anti-offset servo motor and using method thereof

A servo motor and anti-offset technology, applied in the field of servo motors, can solve problems such as output shaft wear, loose fixing screws, and motor output shaft offset, and achieve the effect of reducing wear and reducing the probability of screw loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

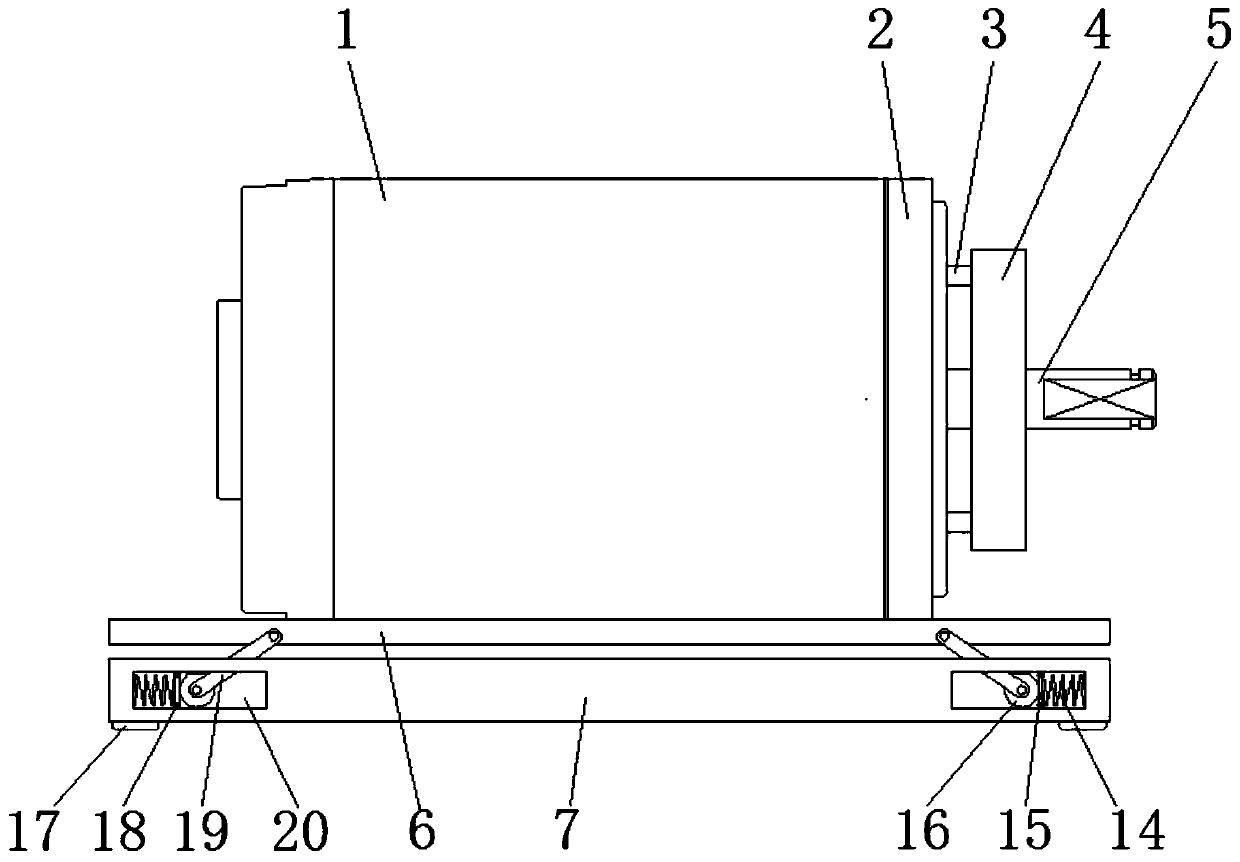

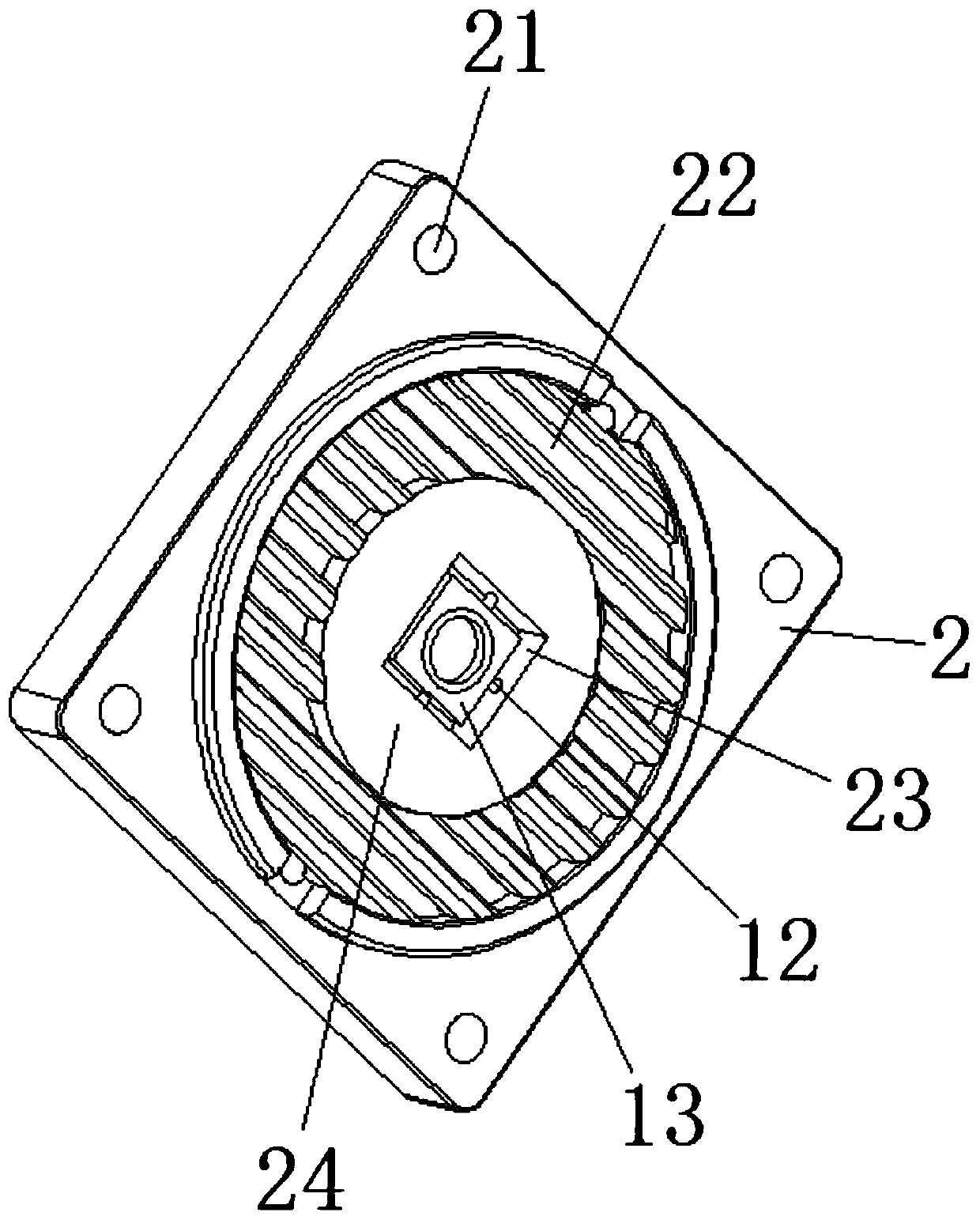

[0027] Example 1: Please refer to figure 1 , figure 2 , an anti-offset servo motor and its use method, comprising a servo motor 1 and a front end cover 2 on its front end, and a mounting base 6 on the bottom surface, and also includes an output shaft 5 of the servo motor 1, the front end cover 2 is integrated It is formed into a rectangular structure in section, and the four corners of the surface of the front end cover 2 are provided with installation holes 21 for screws to be installed on the front end of the servo motor 1, and the surface of the front end cover 2 is formed with a plurality of heat dissipation grooves 22 arranged side by side at equal distances To form a circular heat dissipation area, and the centers of the plurality of heat dissipation grooves 22 are fixedly connected with a support part 24, and a bearing seat 13 is arranged in the support part 24, and the output shaft 5 is positioned and fitted through the bearing seat 13, ensuring that the output shaft ...

Embodiment 2

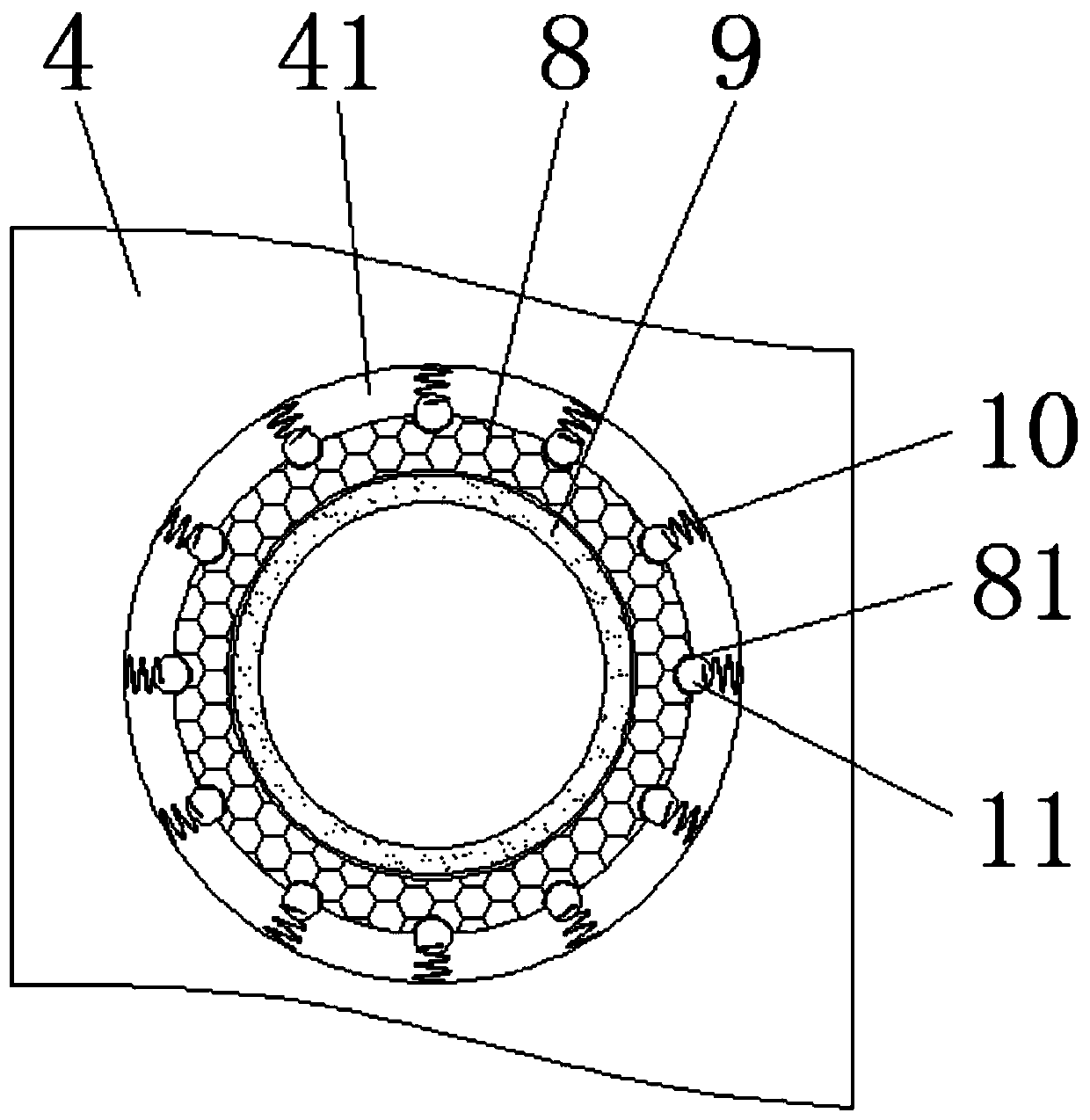

[0030] Example 2: Please refer to figure 1 , image 3 , this embodiment adds the following technical features on the basis of Embodiment 1:

[0031] The output shaft 5 is provided with a compensation mechanism, a plurality of symmetrical installation rods 3 fixedly connected to the outer surface of the front end cover 2, and the end of the installation rod 3 away from the front end cover 2 is fixedly connected to the limit plate 4, and the surface of the limit plate 4 A perforation 41 is opened in the middle, and a limit ring 9 is connected to the perforation 41 through a compensation mechanism. The limit ring 9 is used for passing through the output shaft 5 , and the limit ring 9 and the output shaft 5 are arranged coaxially and do not touch each other.

[0032] Further, the compensation mechanism includes one end of a plurality of springs 10 fixedly connected to the peripheral surface of the perforation 41, and the other ends of the plurality of springs 10 are all facing th...

Embodiment 3

[0034] Example 3: Please refer to figure 1 , this embodiment adds the following technical features on the basis of Embodiment 1 or Embodiment 2:

[0035] The mounting base 6 of the servo motor 1 is connected to a bottom plate 7 through a shock absorbing mechanism, the shock absorbing mechanism includes a cavity 20 formed at the four corners inside the bottom plate 7, and both sides of the bottom plate 7 are symmetrically connected to one end of a buffer rod 19, four buffers The rod 19 deviates from the central axis of the bottom plate 7 and is arranged obliquely downward, and the other end of the buffer rod 19 passes through the through groove on the upper surface of the bottom plate 7 to the corresponding cavity 20 and is hinged with a roller 16, which rolls in contact with the upper and lower surfaces of the cavity 20 , and the end face of the cavity 20 is connected to one end of the compression spring 14, the other end of the compression spring 14 is connected to one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com