Linked swing gun device of hot air seam sealing machine

A sealing machine and seam technology, applied in the direction of sewing tools, etc., can solve the problems of inaccurate positioning and small range of movement of swinging guns, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

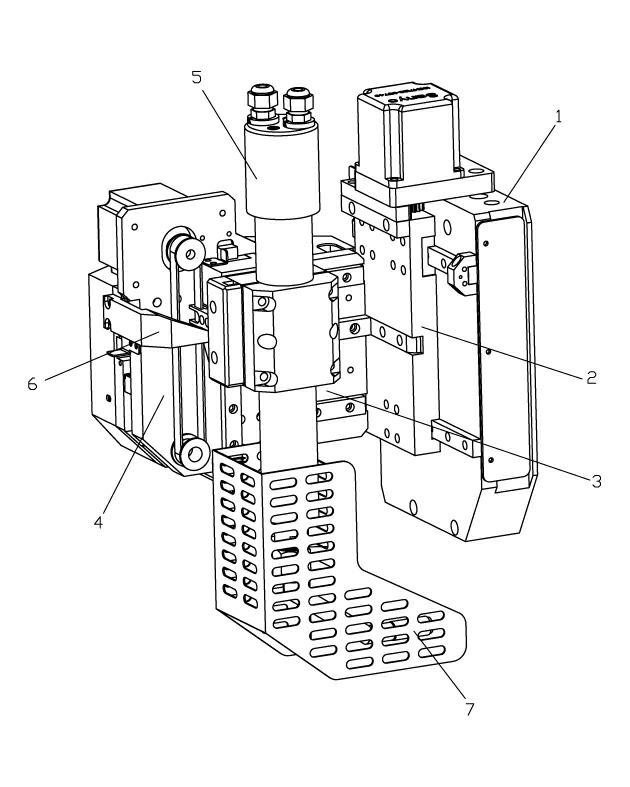

[0021] refer to figure 1 , 2 , 3, 4 and Figure 5 , the linkage pendulum gun device of the hot air seam sealing machine of the present invention, comprises support 1, the forward and backward movement mechanism 2 that is installed on the support 1, the left and right movement mechanism 3 that is installed on the front and rear movement mechanism 2, and is installed on the left and right movement mechanism 3 Up and down moving mechanism 4 on the upper and lower moving mechanism 4 is fixedly connected with pendulum gun 5.

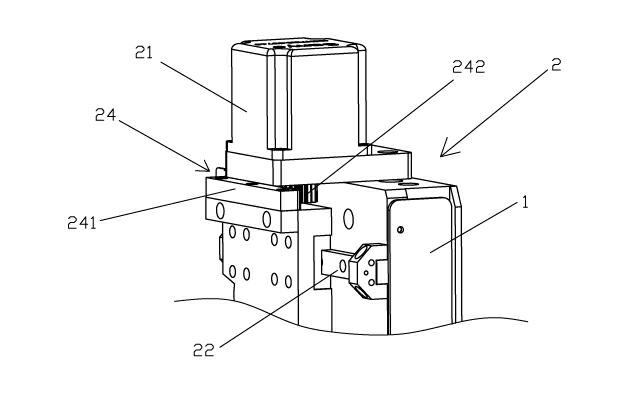

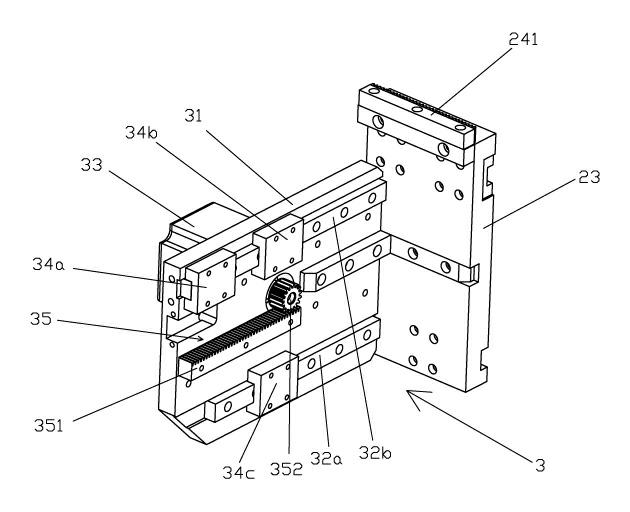

[0022] The front and rear moving mechanism 2 comprises the front and rear drive motor 21 installed on the top of the support 1, the front and rear guide rails 22 fixed on the side of the support 1, the front and rear sliders 23 installed on the front and rear guide rails 22, and the front and rear drive motors 21. Block 23 is connected, and front and rear slide block 23 is connected with left and right moving mechanism 3, and front and rear driving motor 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com