A double-sided printing method for a material

A coding and double-sided technology, applied in the field of coding, can solve the problems of long time spent, etc., and achieve the effects of improving production efficiency, saving coding time, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

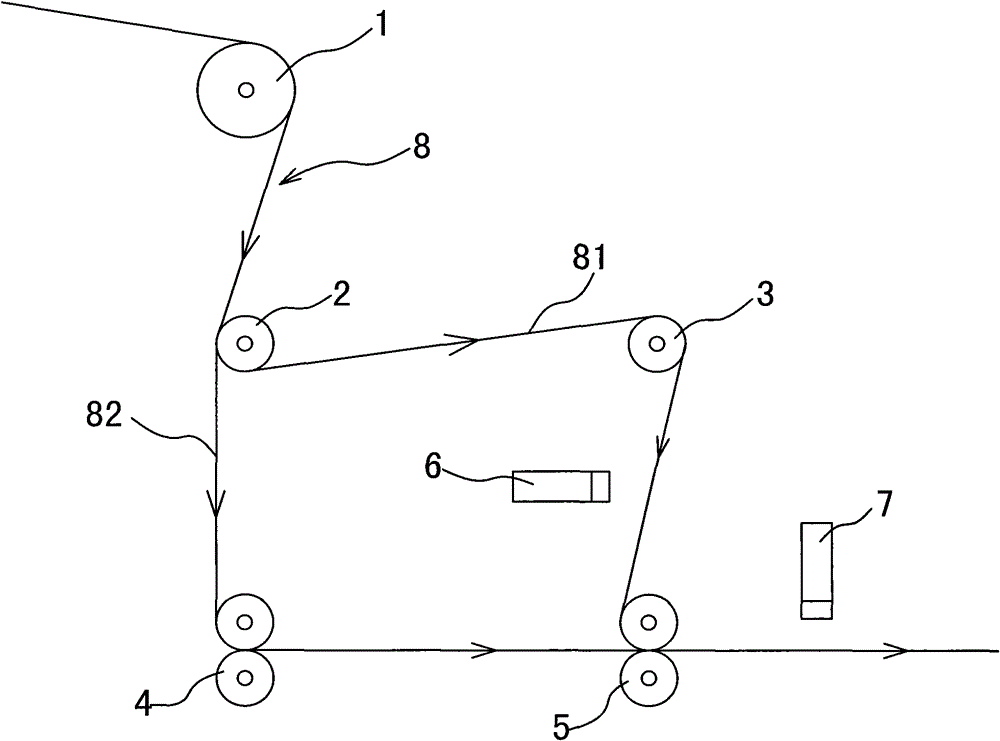

[0036] see figure 1 , a double-sided coding method for self-adhesive materials, the steps are:

[0037] 1. Pass the self-adhesive material 8 through the feed roller 1. The function of the feed roller 1 is to unfold and straighten the self-adhesive material 8, so that the self-adhesive material can meet the conditions for the implementation of the next step;

[0038] 2. After being unfolded and stretched by the feed roller 1, the self-adhesive material 8 passes through the peeling roller 2, and the self-adhesive material surface material 81 and the release paper 82 are manually peeled off when feeding for the first time , after the self-adhesive material surface material 81 is peeled off from the release paper 82, the adhesive surface of the self-adhesive material surface material 81 is exposed, which is convenient for the next step to spray code on the adhesive surface of the self-adhesive material surface material 81 . Simultaneously because after the self-adhesive material...

Embodiment 2

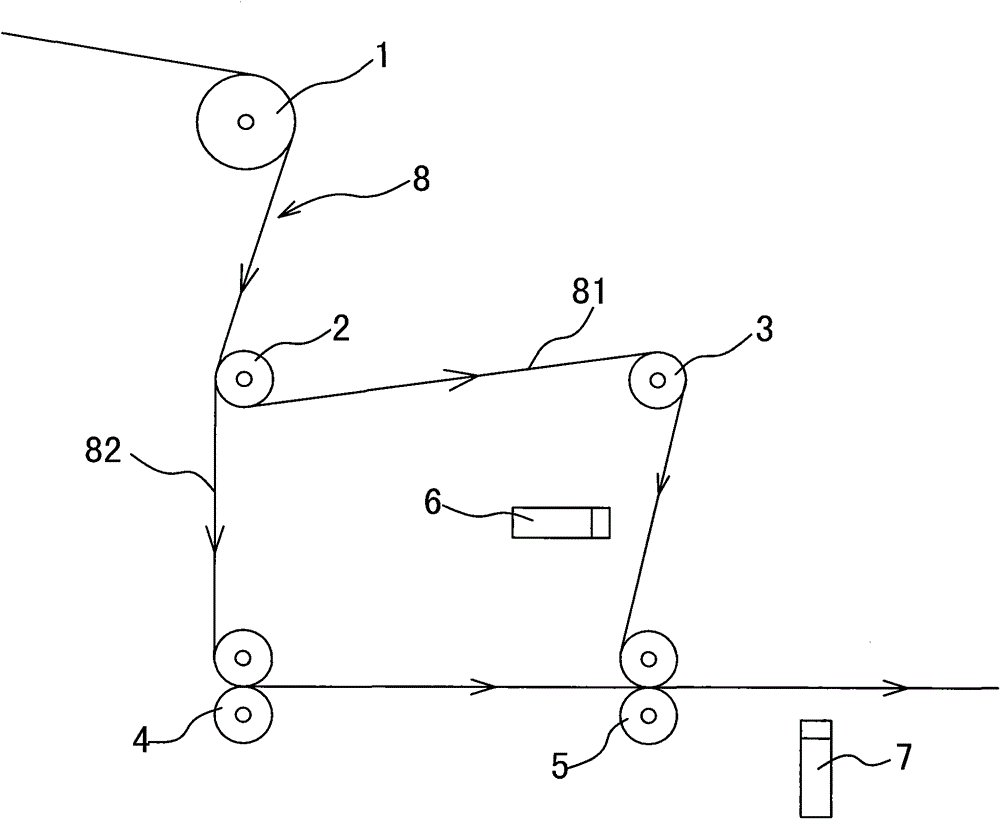

[0044] see figure 2 , a double-sided coding method for self-adhesive materials, the steps are:

[0045] 1. Pass the self-adhesive material 8 through the feed roller 1. The function of the feed roller 1 is to unfold and straighten the self-adhesive material 8, so that the self-adhesive material can meet the conditions for the implementation of the next step;

[0046] 2. After being unfolded and stretched by the feed roller 1, the self-adhesive material 8 passes through the peeling roller 2, and the self-adhesive material surface material 81 and the release paper 82 are manually peeled off when feeding for the first time , after the self-adhesive material surface material 81 is peeled off from the release paper 82, the adhesive surface of the self-adhesive material surface material 81 is exposed, which is convenient for the next step to spray code on the adhesive surface of the self-adhesive material surface material 81 . Simultaneously because after the self-adhesive materia...

Embodiment 3

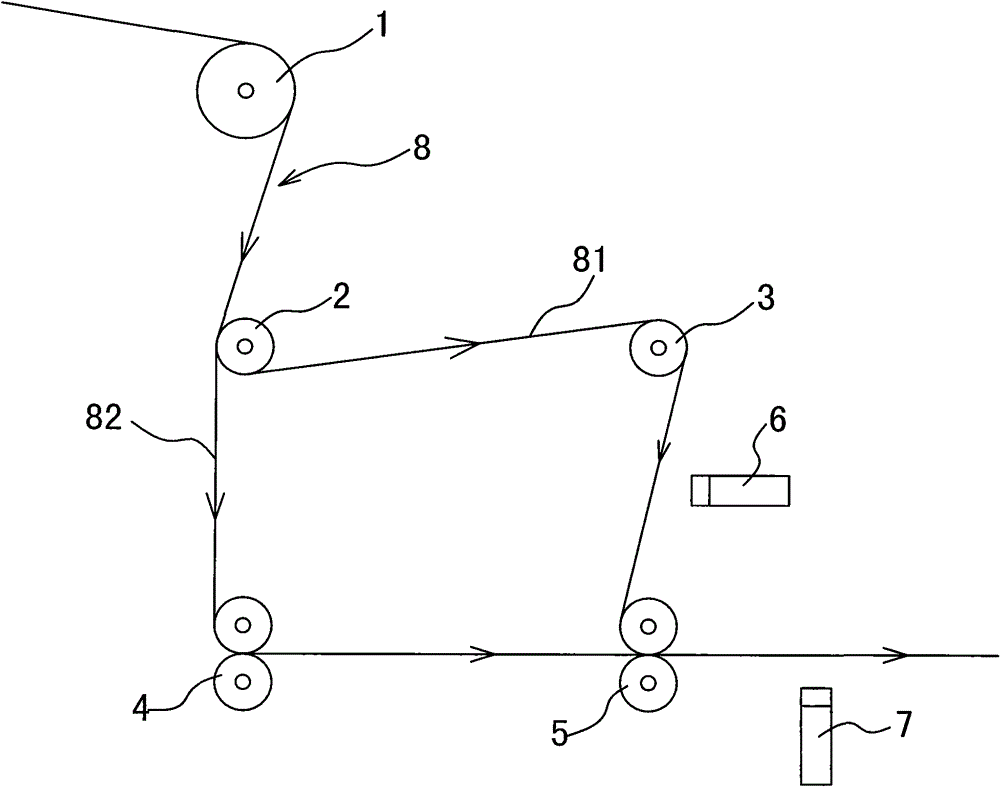

[0052] see image 3 , a double-sided coding method for self-adhesive materials, the steps are:

[0053]1. Pass the self-adhesive material 8 through the feed roller 1. The function of the feed roller 1 is to unfold and straighten the self-adhesive material 8, so that the self-adhesive material can meet the conditions for the implementation of the next step;

[0054] 2. After being unfolded and stretched by the feed roller 1, the self-adhesive material 8 passes through the peeling roller 2, and the self-adhesive material surface material 81 and the release paper 82 are manually peeled off when feeding for the first time After peeling off the self-adhesive material surface material 81 and the release paper 82, the adhesive surface of the self-adhesive material surface material 81 is exposed. Simultaneously because after the self-adhesive material surface material 81 and the release paper 82 are peeled off, the adhesive surface of the self-adhesive material surface material 81 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com