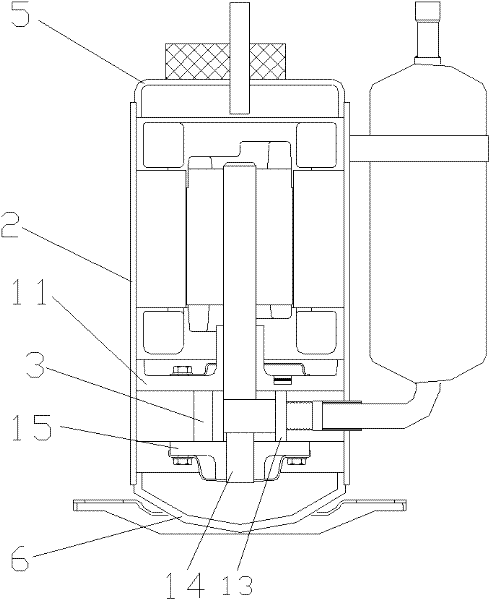

Rotary compressor

A technology of rotating compressors and sliders, applied in the field of compressors, can solve the problems of energy loss, reduction of suction chamber volume, and decrease of compressor suction efficiency, and achieve the effect of reducing suction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

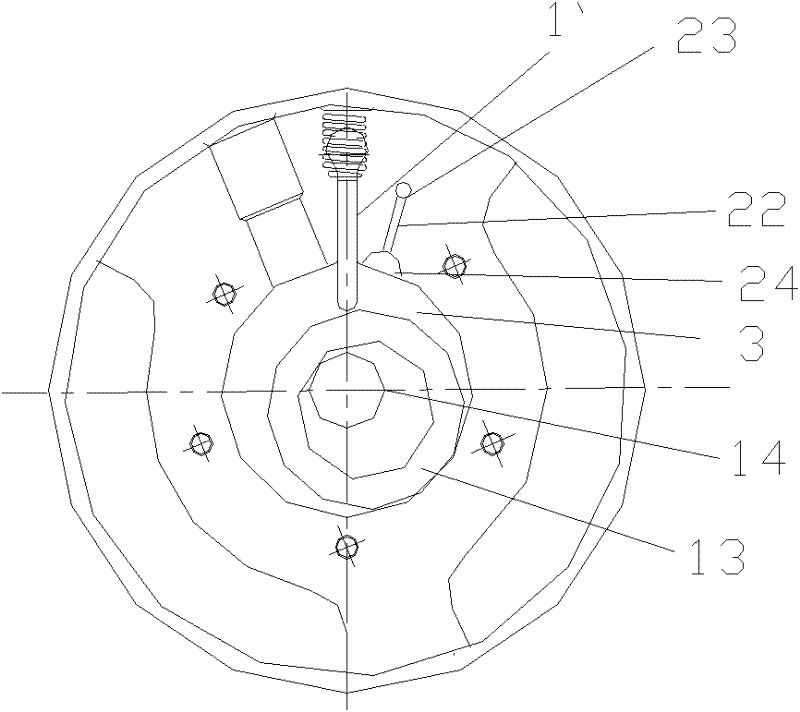

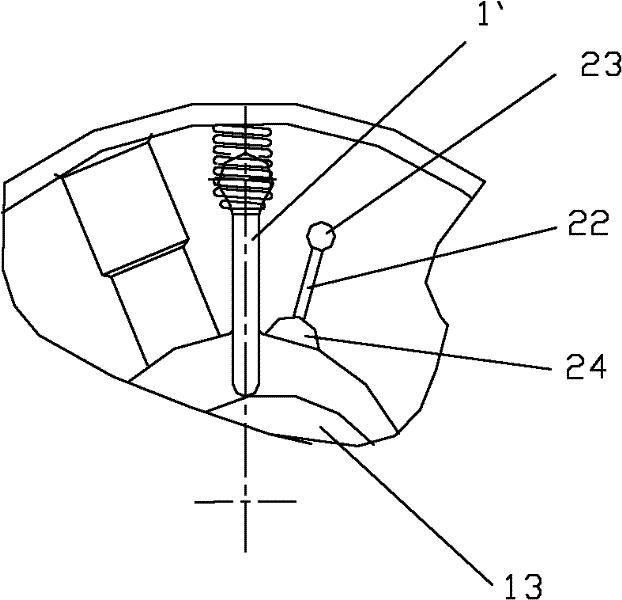

[0022] Such as Figure 4 As shown, the slider is composed of two sliders 20, 21 that can move relative to each other, and the communication passages 12 of the two sliders 20, 21 are arranged at corresponding positions, forming an exhaust cutout 24 and a resonance chamber 23 that can communicate with each other. The opening and closing of the resonance chamber are realized when the two sliders 20 and 21 are in different positions.

[0023] When the cylinder 3 compresses the gas, the two sliders 20, 21 move to a specific position, and when the opening of the communication passage 12 is connected (intersecting or overlapping) with the opening of the exhaust small groove 22, the exhaust notch 24 and the resonance cavity 23 are communicated. When inhaling, the communication channels 12 of the sliders 20 and 21 are closed by the side walls of the slider grooves to cut off the exhaust cutout 24 and the resonance chamber 23. The high-pressure gas column in the resonance chamber cannot...

Embodiment 2

[0029]In this embodiment, the cross-sectional area of the communication passage 12 is larger than the opening of the small exhaust groove 22 on the side wall of the groove of the slider. By properly enlarging the communication channel 12 of the two sliders 20, 21, the range of the piston rotation angle for the exhaust notch 24 and the resonance cavity 23 to still be in communication can also be enlarged.

[0030] Other structures of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com