High-temperature pipeline vibration isolator on plane

A vibration isolator and high-temperature tube technology, applied in the aviation field, can solve the problems of demanding working medium and working environment, large creep, short service life, etc., and achieve large angular displacement, small change in characteristics, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

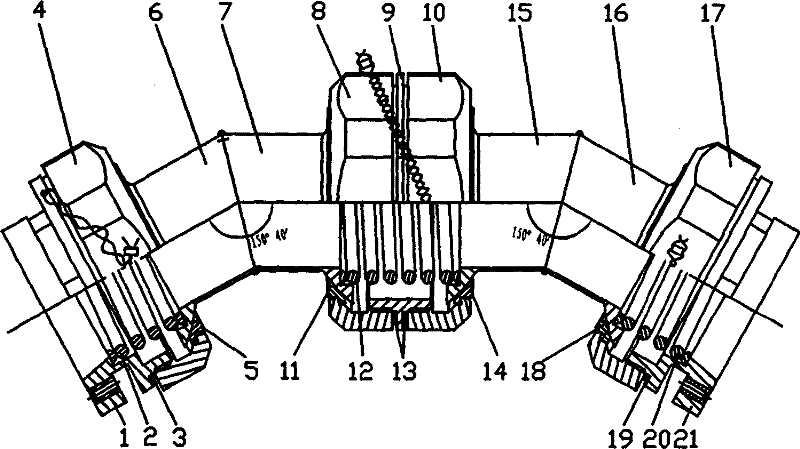

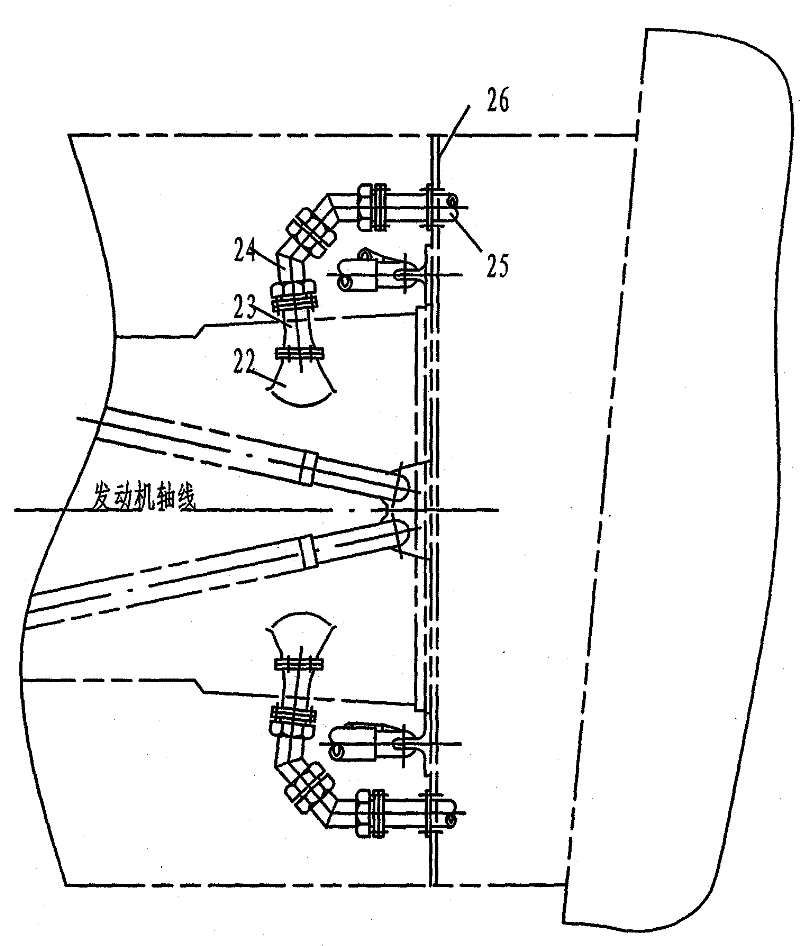

[0032] The pipeline 23 and the pipeline 25 connected to the two ends of the high-temperature pipeline vibration isolator 24 are respectively fixed on the engine air inlet 22 and the frame web 26 of the engine room, and the combined welding angle of the three vibration isolation mechanisms is 150°40 '. When the engine is working, the vibration force generated is transmitted to the high-temperature pipeline vibration isolator 24 through the conduit 23. Under its vibration isolation effect, the vibration force is eliminated, and the transmission of the vibration force to the pipeline 25 is cut off, so as to avoid the pipeline from being damaged due to damage due to vibration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com