Structure for fixing magnetic poles of permanent magnet motor

A technology of fixed magnetic poles and permanent magnet motors, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of unreliable positioning of rotor magnetic poles, and achieve easy implementation, improved processing efficiency, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

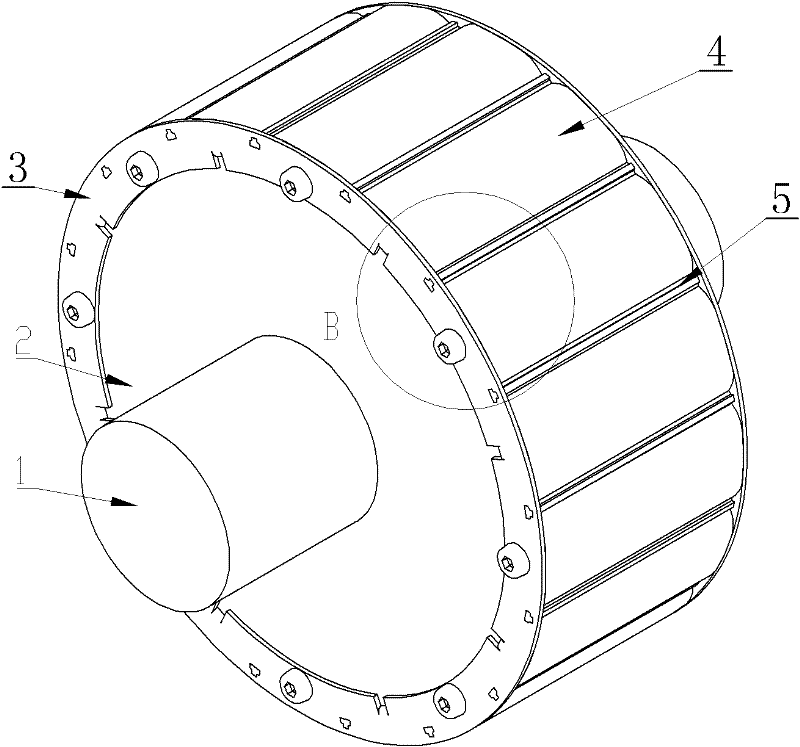

[0029] Specific implementation mode one: the following combination Figure 1 to Figure 6 To describe this embodiment,

[0030] This embodiment includes a rotating shaft 1 and a rotor yoke 2. The rotor yoke 2 is sleeved on the outer surface of the rotating shaft 1. It also includes two annular rotor pressure plates 3, P magnetic poles 4 and P positioning keys 5.

[0031] Two ring-shaped rotor pressure plates 3 are respectively fixedly connected to both ends of the rotor yoke 2, and form grooves with the outer surface of the rotor yoke 2. P positioning keys 5 are evenly distributed along the circumferential direction of the rotor, and the grooves are evenly divided. There are P accommodating spaces along the axial direction of the rotor, and one magnetic pole 4 is fixedly arranged in each accommodating space.

specific Embodiment approach 2

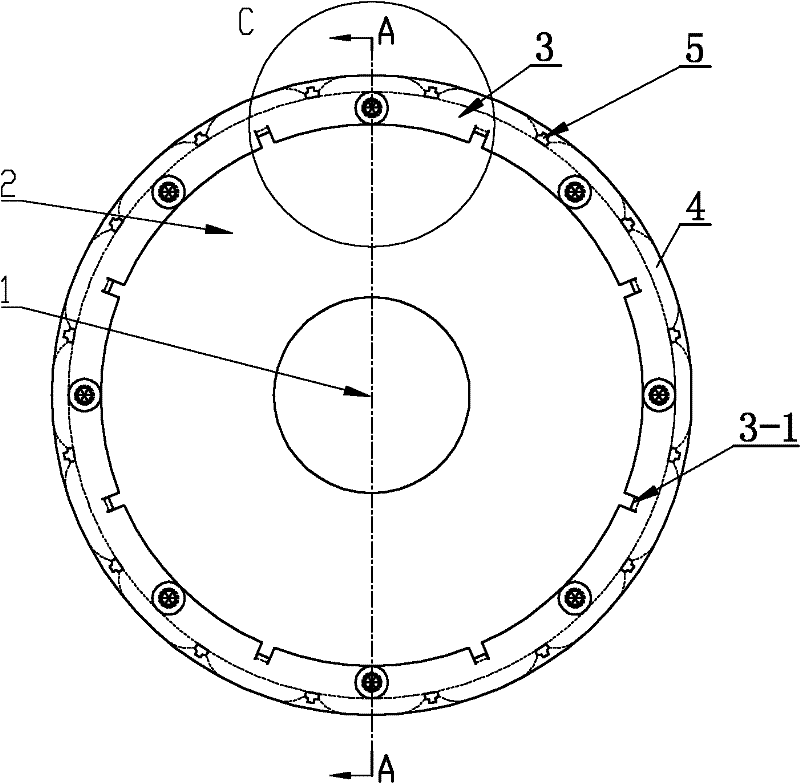

[0032] Specific implementation mode two: the following combination Figure 1 to Figure 9 Describe this embodiment, this embodiment is a further description of Embodiment 1,

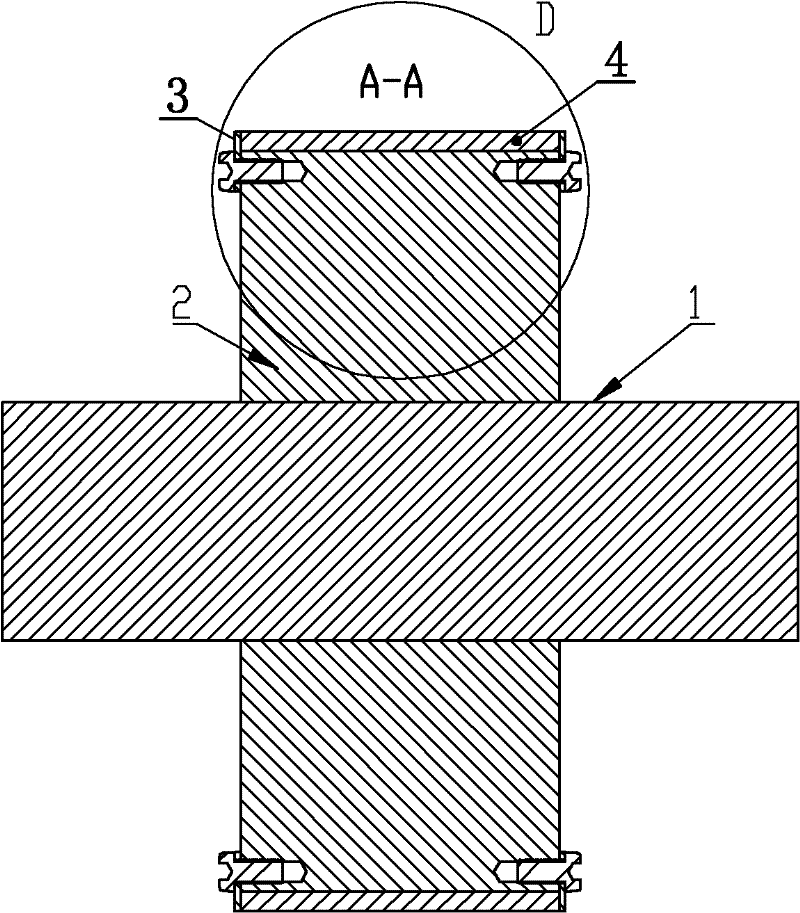

[0033] A plurality of positioning pins 3-1 are stamped on each annular rotor pressure plate 3, and a positioning hole 2-1 is provided on the rotor yoke 2 corresponding to each positioning pin 3-1. The positioning pin 3-1 is tenon-jointed with the positioning hole 2-1 one by one; each annular rotor pressure plate 3 is fixedly connected with the rotor yoke 2 through a plurality of screws, and the plurality of screws are evenly distributed on the annular rotor pressure plate 3 , and spaced apart from the positioning pin 3-1.

[0034] Others are the same as the first embodiment.

[0035] In this embodiment, a plurality of positioning pins 3 - 1 are respectively embedded in a plurality of positioning holes 2 - 1 to realize the positioning of the annular rotor pressure plate 3 in the circumferential direction...

specific Embodiment approach 3

[0036] Specific implementation mode three: the following combination Figure 1 to Figure 9 Describe this embodiment, this embodiment is a further description of Embodiment 1 or 2,

[0037] P slots 3-2 are uniformly arranged on each annular rotor pressure plate 3, and each slot 3-2 is used to fix one end of a positioning key 5.

[0038] Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com