Standard laminated plate and manufacturing method thereof

A production method and technology of laminated boards, applied in the direction of multi-layer circuit manufacturing, etc., can solve problems such as low pass rate, abnormal expansion and contraction of core boards, unqualified laminated boards, etc., and achieve the effect of improving the pass rate

Active Publication Date: 2011-06-15

新方正控股发展有限责任公司 +1

View PDF5 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the method of mechanically drilling the plywood is mainly to drill holes directly on the four corners of the plywood, but this method may have the following technical problems: due to the abnormal expansion and contraction of the core board before lamination, and the inner layer deviation Or, there are problems such as interlayer offset after lamination, which makes the plywood scrapped when the plywood is mechanically drilled; if the plywood needs to be produced in large quantities, the plywood is used as the standard press If the plywood is used, it may lead to unqualified plywood obtained in mass production, and the pass rate is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

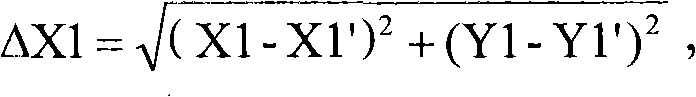

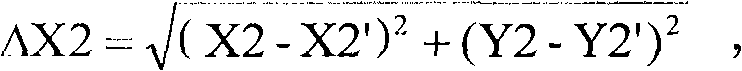

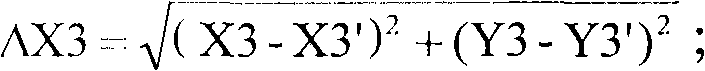

The invention discloses a standard laminated plate and a manufacturing method thereof, which aim to improve the passing rate of laminated plates. The method comprises the following steps of: setting a test part on core plates for lamination and manufacture; stacking a plurality of the core plates and performing laminating operation to obtain the laminated plate; according to the position of the test part of a plurality of the core plates, mechanically drilling the corresponding position of the laminated plate to obtain mechanical holes; performing interlayer offset detection on the mechanically drilled laminated plate to judge whether the laminated plate is qualified. The technical scheme of the invention ensures that the standard laminated plate is the qualified laminate plate, thereby improving the passing rate of the laminated plates which are manufactured in batch by taking the standard laminated plate as the standard, and reducing the rejection rate of the laminated plates manufactured in batch.

Description

Method for making standard plywood and standard plywood technical field The invention relates to the field of manufacturing printed circuit boards, in particular to a method for manufacturing a standard laminated board and a standard laminated board. Background technique At present, in the process of producing a PCB board (Printed Circuit Board, printed circuit board), each layer of core board is laminated to obtain a laminated board, and the laminated board needs to be mechanically drilled before entering the next process. At present, the method of mechanically drilling the plywood is mainly to directly drill holes on the four corners of the plywood, but this method may have the following technical problems: due to the abnormal expansion and contraction of the core board before lamination, the inner layer is biased Or, there are problems such as interlayer offset after lamination, which makes the plywood scrapped when the plywood is mechanically drilled; if the plywood ne...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H05K3/46

Inventor 王霏霏彭家仙

Owner 新方正控股发展有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com