Sliding track without rolling balls

一种滚珠滑轨、无滚珠的技术,应用在家具零件、家里用具、抽屉等方向,能够解决元件易于损坏、成本高、滚珠滑轨不能继续使用等问题,达到减少元件的使用、承载力强、节省成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

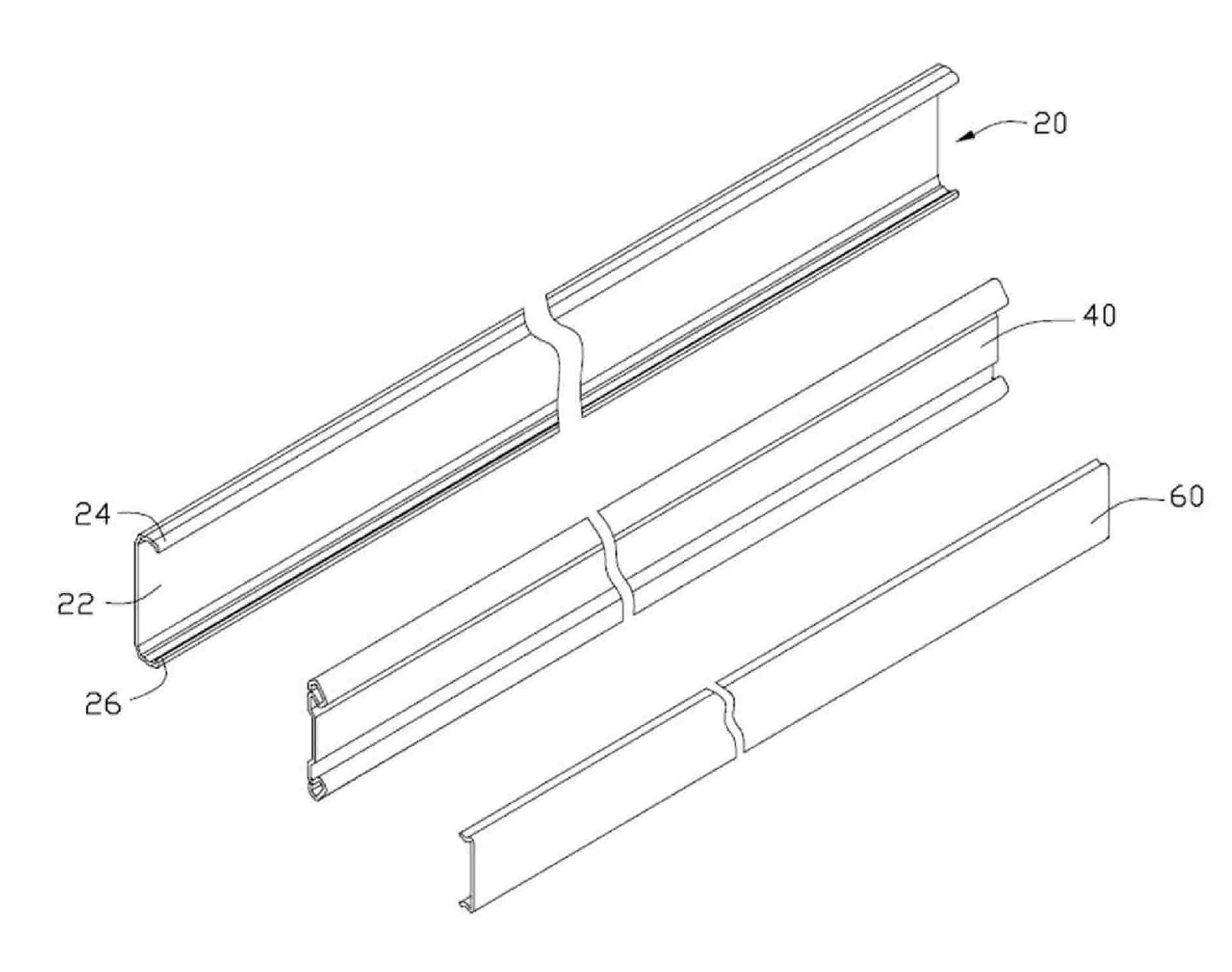

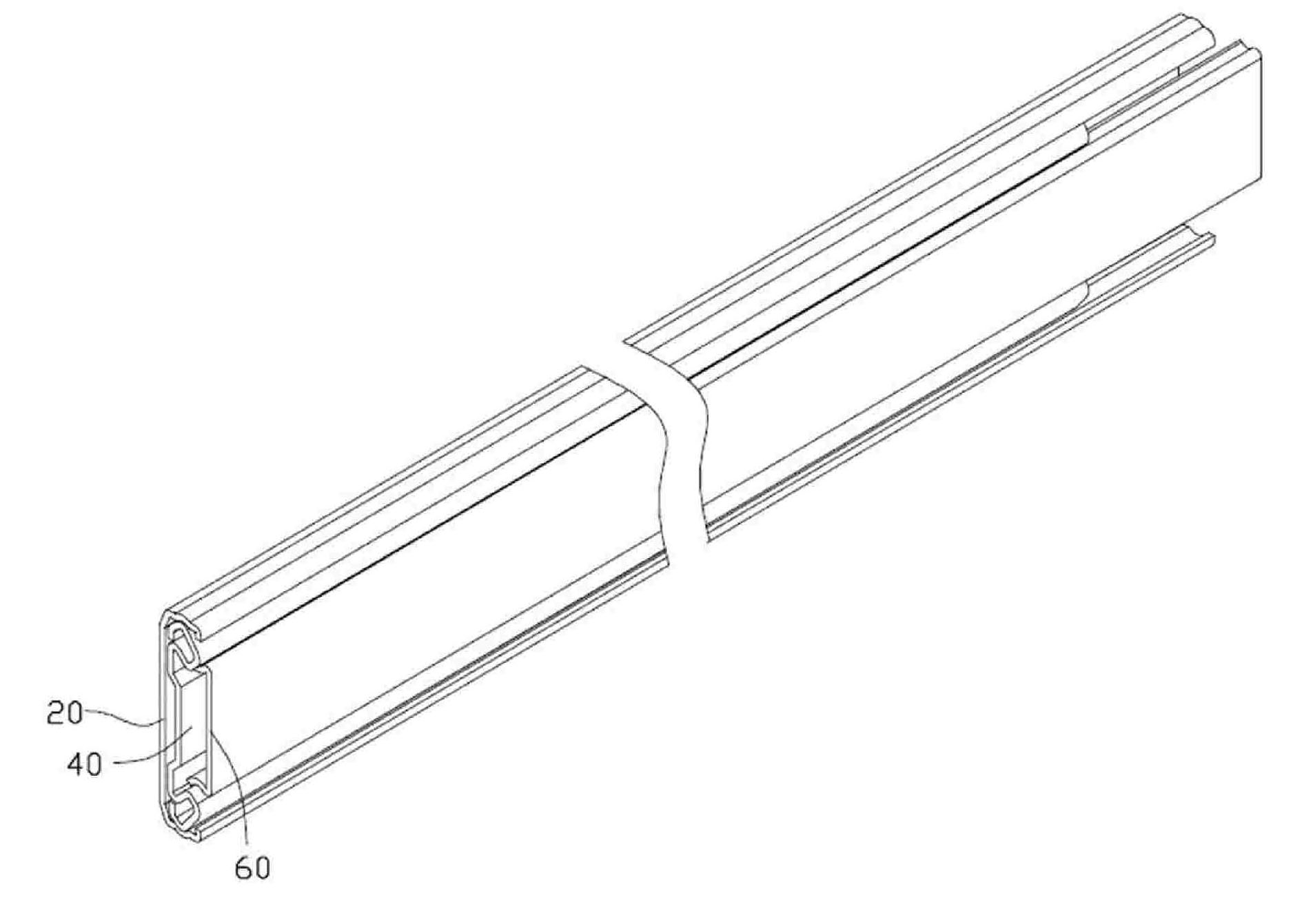

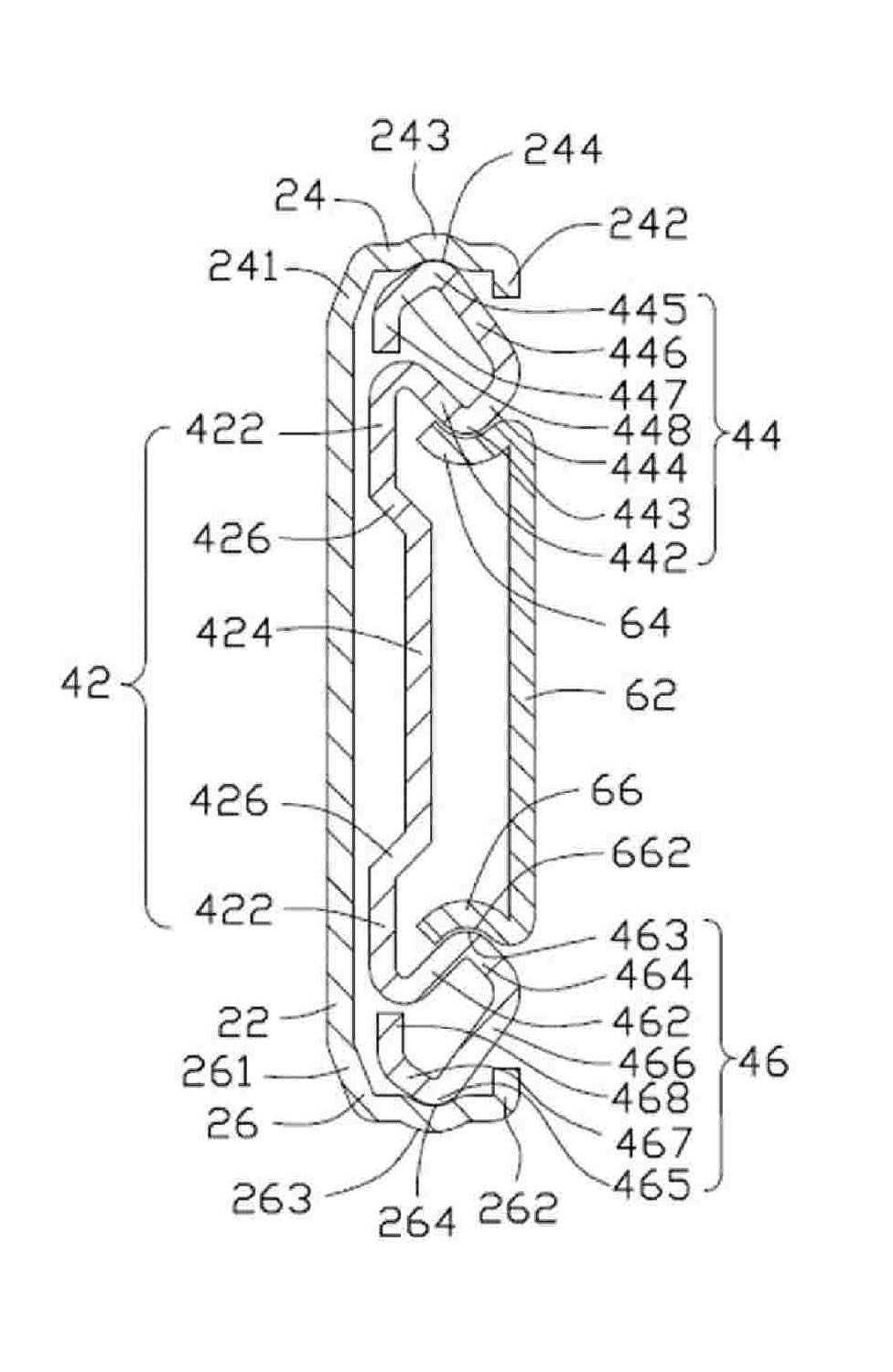

[0012] see figure 1 and figure 2 A preferred embodiment of the ballless slide rail of the present invention includes a first rail body 20, a second rail body 40, a third rail body 60 and a number of positioning devices (not shown) arranged between the rail bodies. One rail body 20 can be fixed on a fixed object, such as a cabinet or a cabinet, the third rail body 60 is fixed on a side wall of a drawer or a server, and the second rail body 40 is accommodated in the first rail body 20 and the third rail body 60, the second rail body 40 and the third rail body 60 can slide relative to the first rail body 20 in the stretching or retracting direction, so as to pull the drawer / server out or push it into the cabinet / cabinet. The positioning device is arranged between adjacent rail bodies to prevent accidental sliding of the corresponding rail body. When the positioning device is in an unlocked state, the corresponding rail body can be stretched or retracted to slide.

[0013] Plea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com