Foundation pile and construction method thereof

A construction method and a technology for foundation piles, which are applied in the directions of foundation structure engineering, sheet pile wall, construction, etc., can solve the problems of high cost, insufficient lateral gripping force of the pipe body 11, weak fixed bonding force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

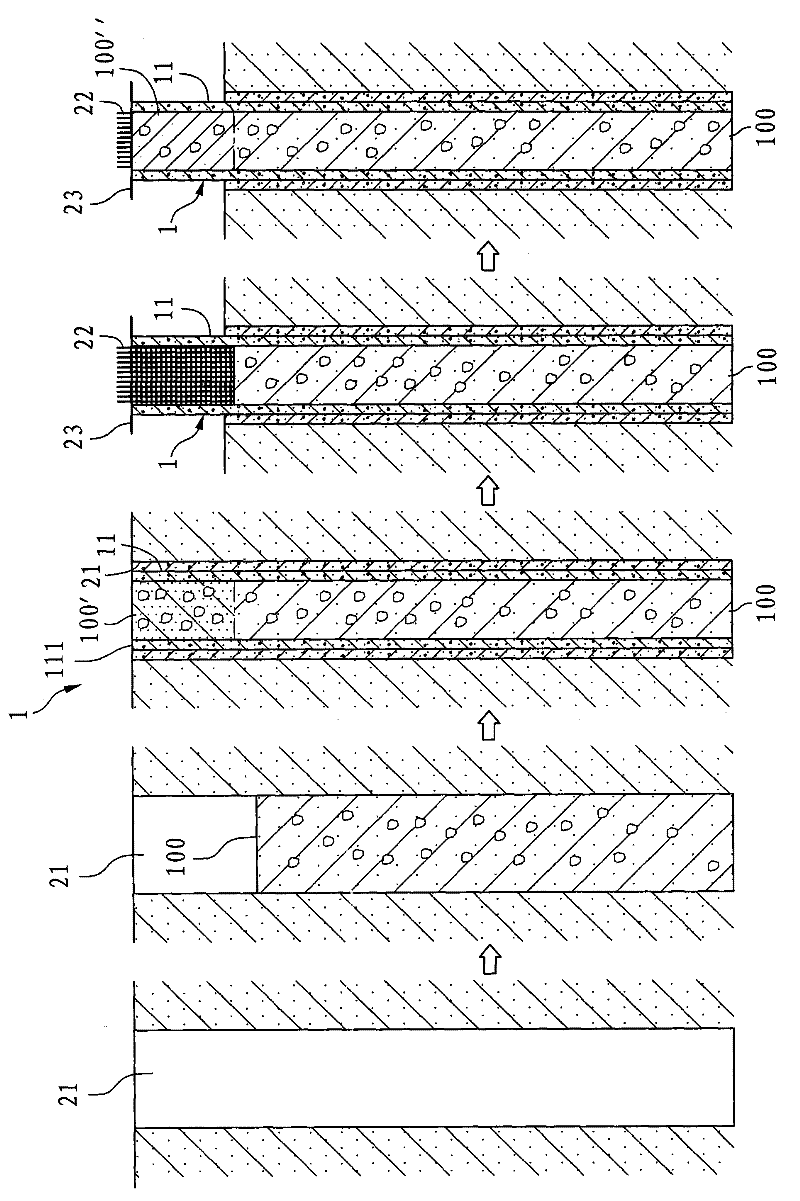

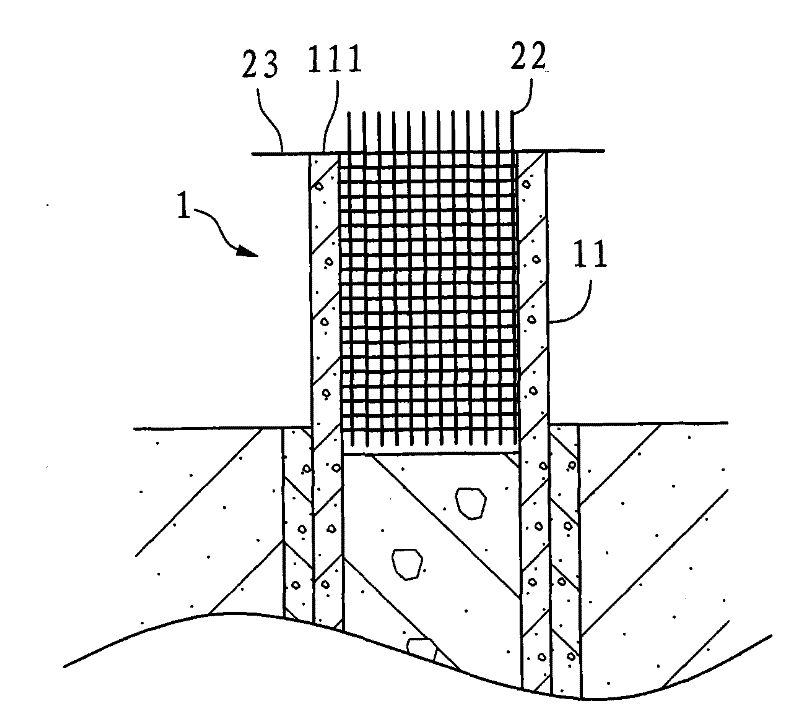

[0044] For further elaborating the technical means and effects that the present invention takes to reach the intended invention purpose, below in conjunction with accompanying drawing and preferred embodiment, to its specific implementation, structure, step, method for the foundation pile proposed according to the present invention and construction method thereof Features and their functions are described in detail below.

[0045] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0046] see Figure 5 , Image 6 Shown are a sectional view and a partially enlarged sectional view of the first preferred embodiment of the foundation pile of the present invention, respectively. The foundation pile 3 of the first preferred embodiment of the present invention includes a top cover 31, a surrounding wall 32 extending downward from the periphery of the top cover 31, and a surrounding wall 32 that is spaced from the top cover 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com