Vertical corn straw shredding and placement machine

A corn stalk and laying machine technology, which is applied to cutters, harvesters, agricultural machinery and implements, etc., can solve the problems of blunt blades, large power consumption, and inability to keep corn stalks for laying, saving power and walking. Fast, comprehensive and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

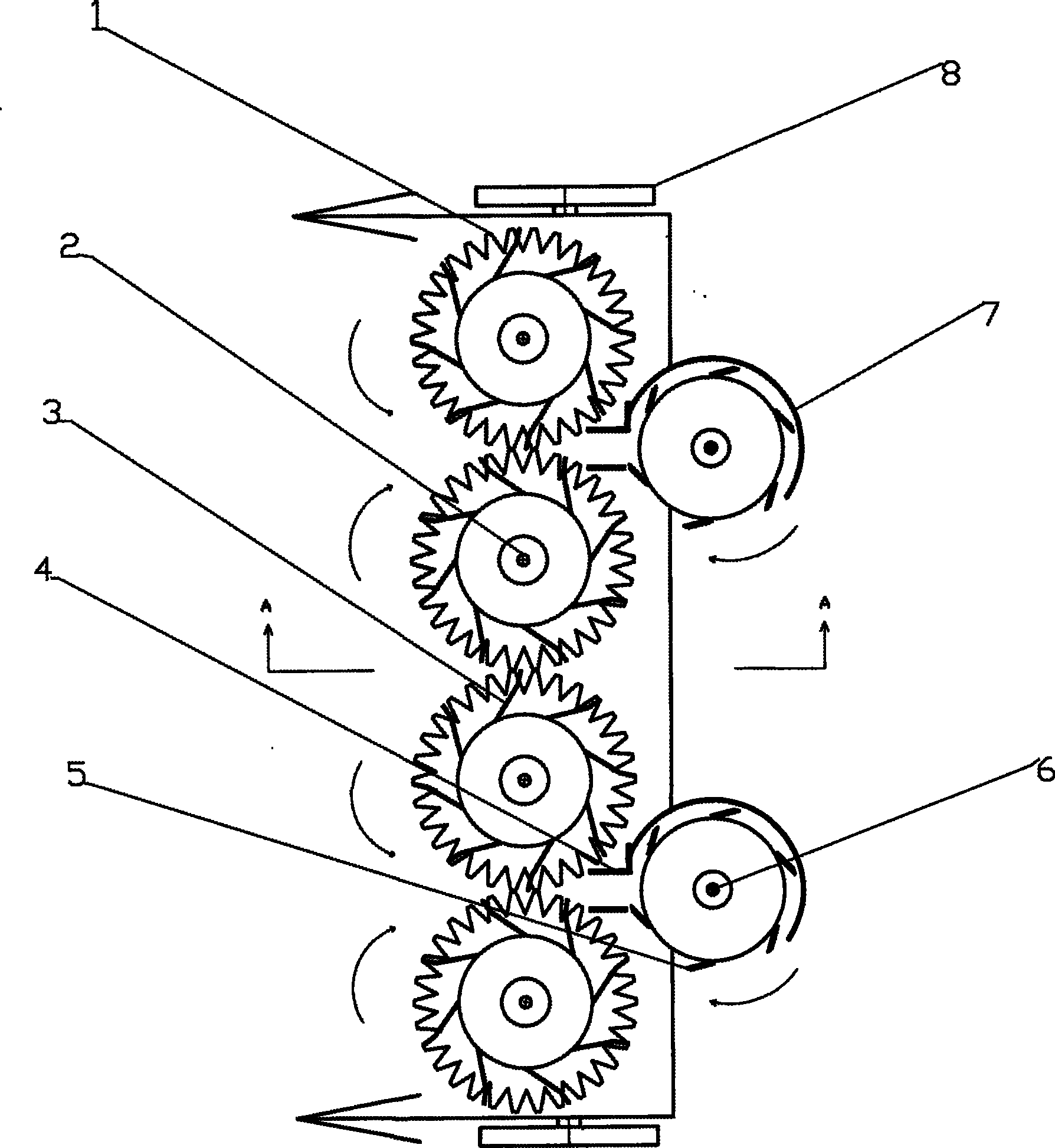

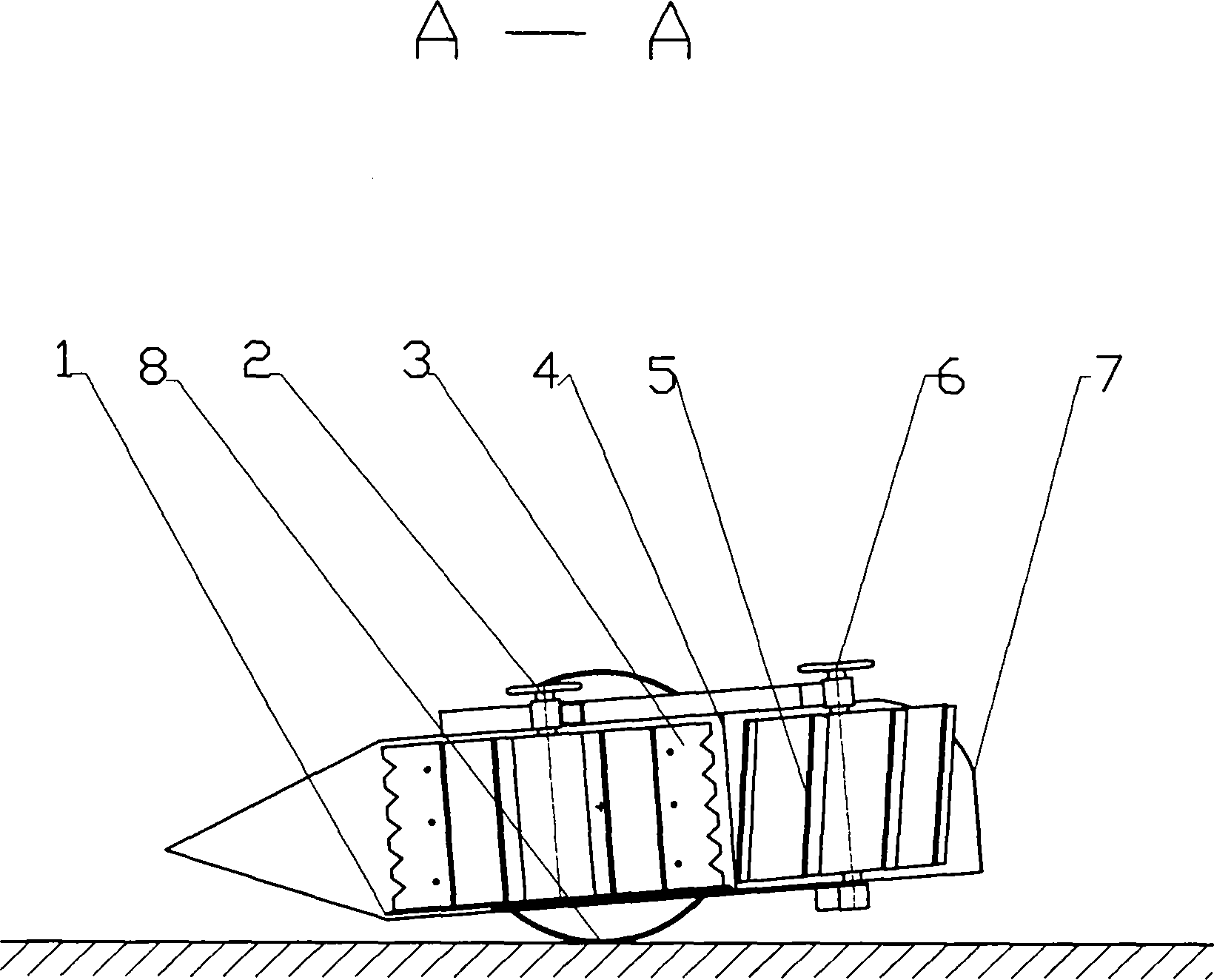

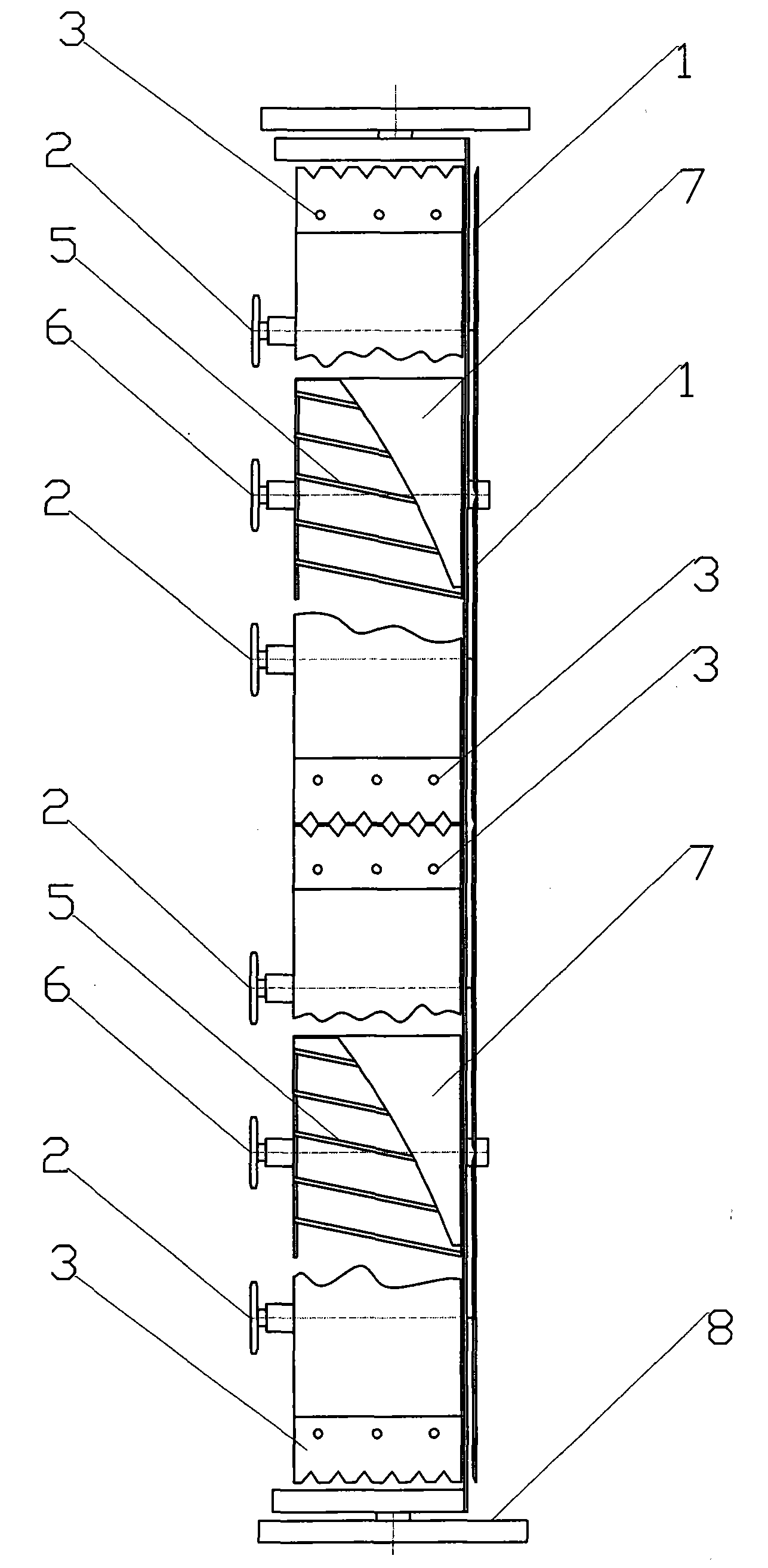

[0012] exist figure 1 The plane of the middle cutter head (1) is parallel to the ground and rotates relative to the adjacent cutter head against the ground. The cutter head (1) is fixed on the vertical shaft (2), and the vertical shaft (2) is close to the vertical direction to the ground. The vertical shaft (2) Several elastic clamping plates (3) are arranged on the top. The cutter head (1), vertical shaft (2), and elastic clamping plate (3) are integrated with the adjacent vertical shaft to form a three-dimensional conveying combination and rotate counter-rotating at the same speed, and are arranged behind the counter-rotating elastic plates (3) Fixed knife (4) is arranged. Fixed knife (4), vertical knife shaft (6), inclined knife (5) form chopping chamber. In this way, the fixed knife (4) and the inclined knife (5) form a three-dimensional cutting straw mode, and the knife does not contact the ground during operation. A semicircular oblique open shield (7) is provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com