Lower stop for closed-end zipper and closed-end zipper using same

A technology for zippers and elastic elements, applied in the field of closed zippers, which can solve the problems of reducing the simplicity of the stopper at the bottom of the zipper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

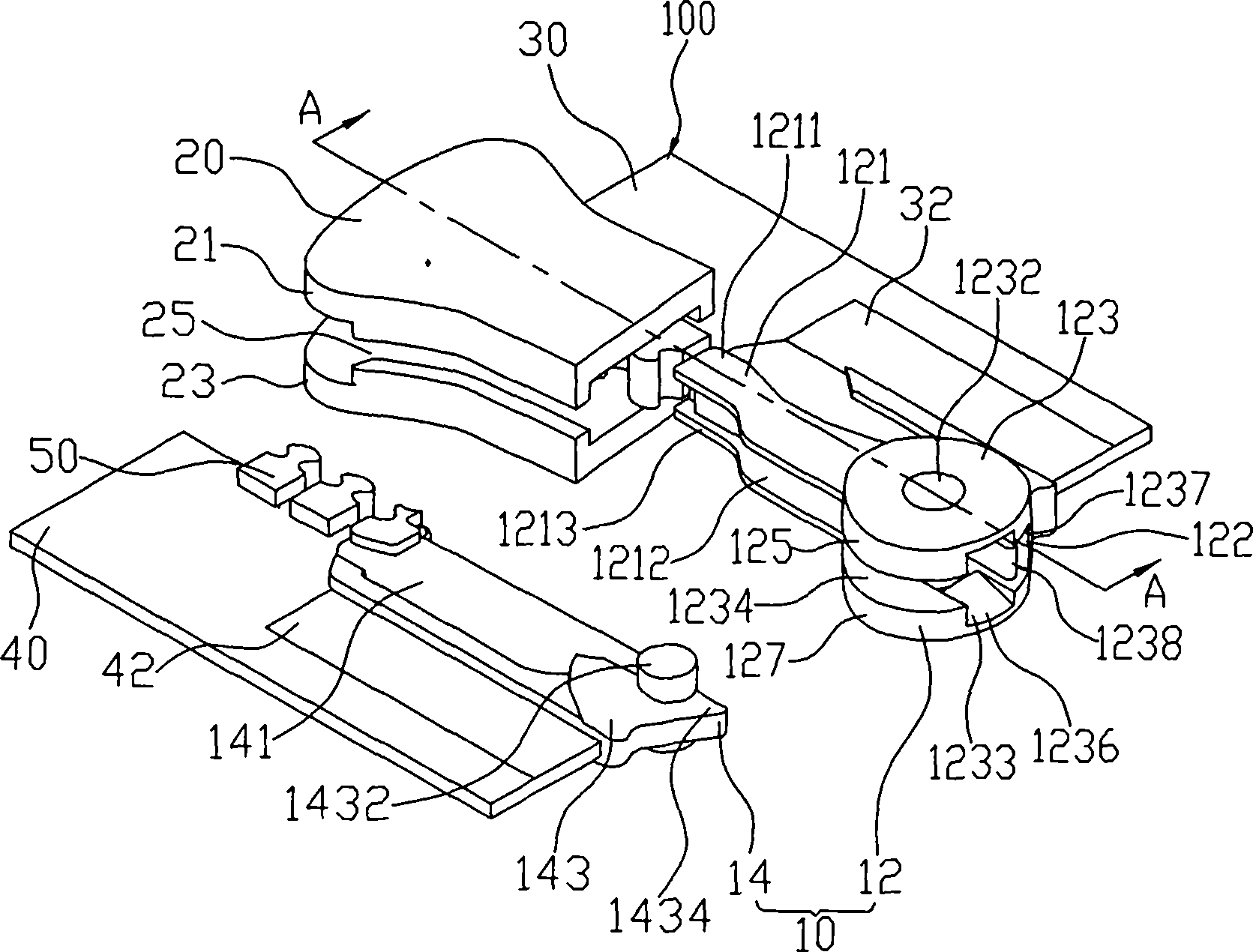

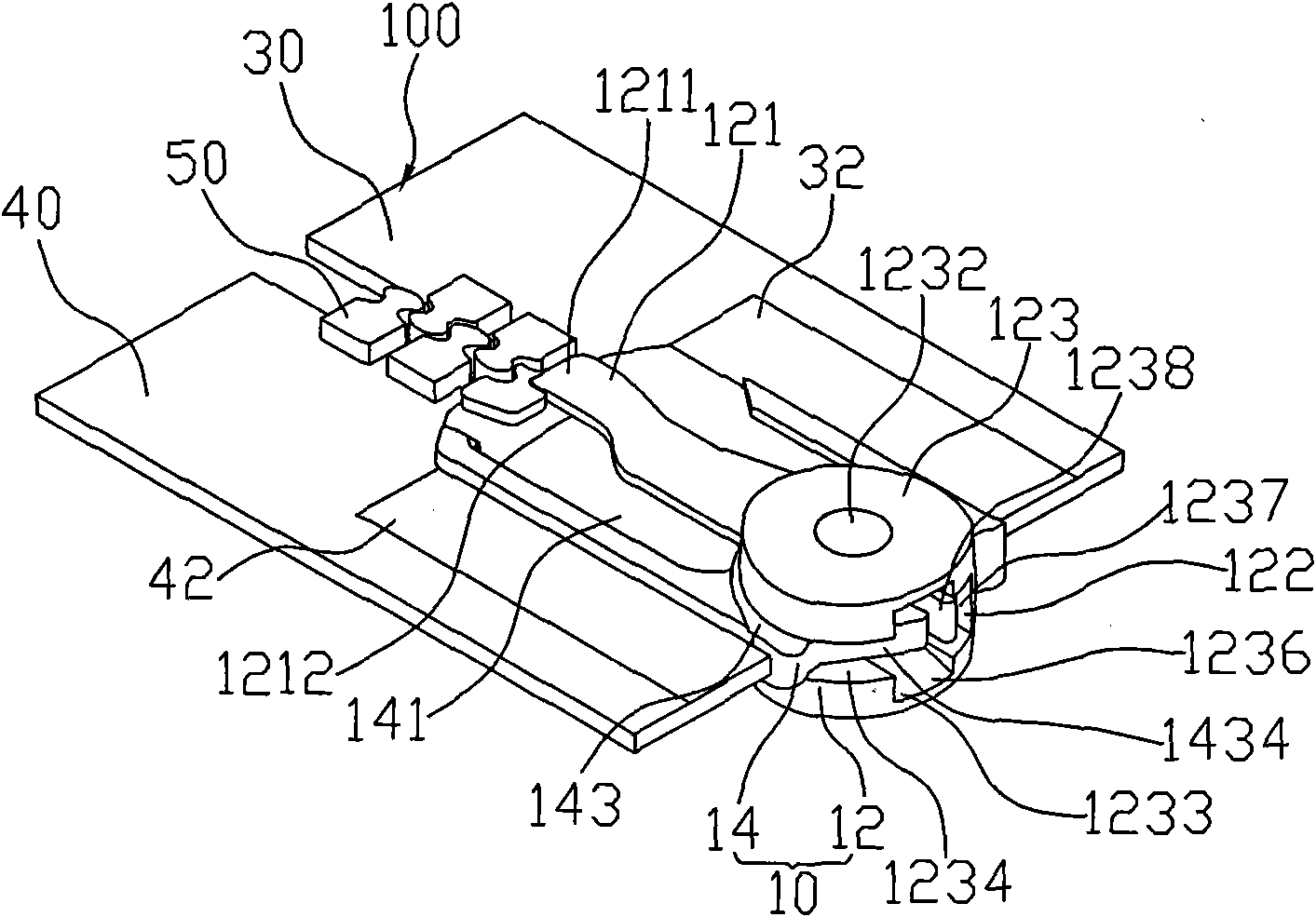

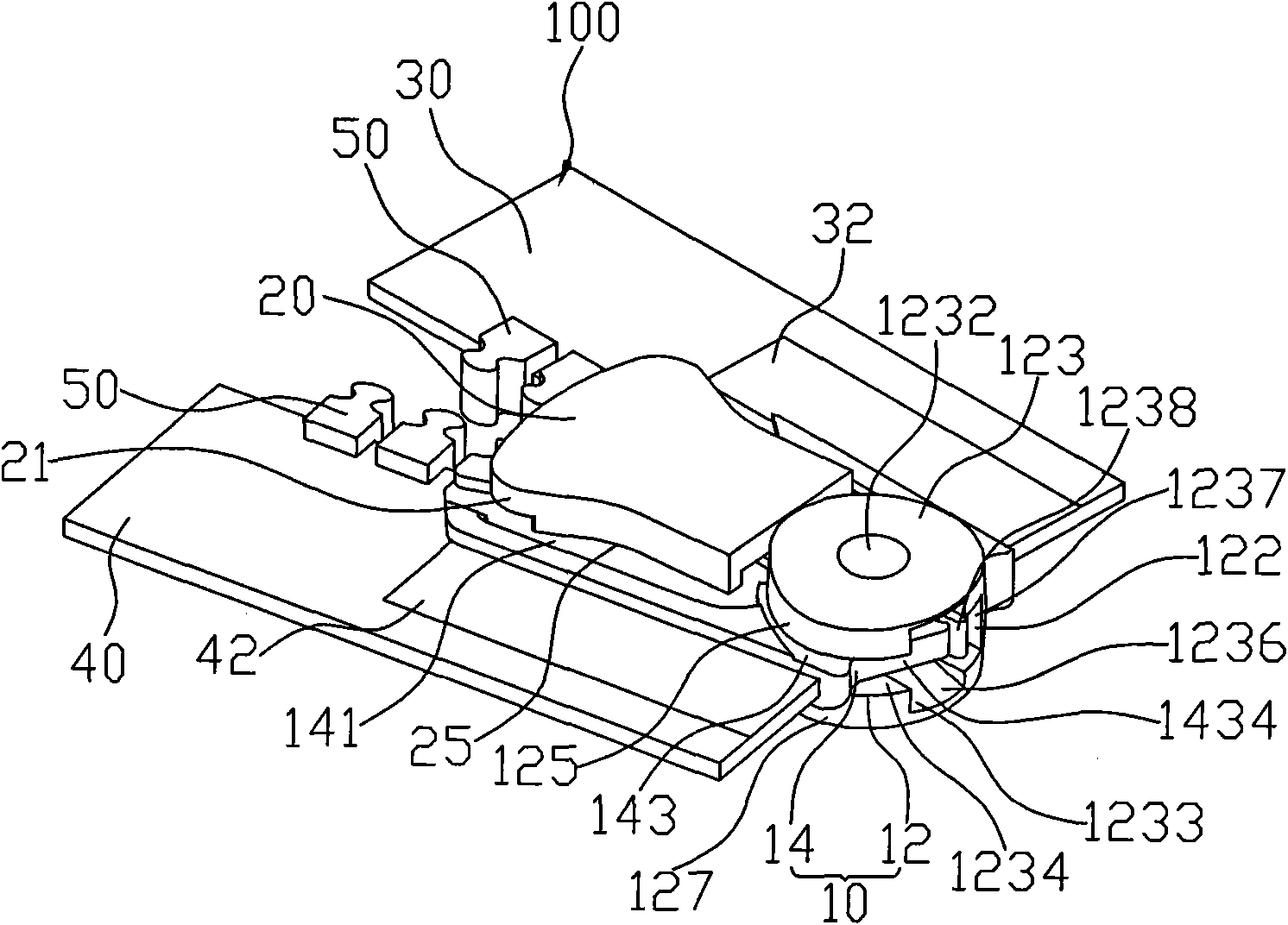

[0046] figure 1 It is a three-dimensional exploded view of the first embodiment of the closed zipper 100 of the present invention. The closed zipper 100 includes a bottom stop 10 , a slider slider 20 , a chain tape 30 and a chain tape 40 . The two chain belts 30, 40 are respectively provided with a row of chain teeth 50 correspondingly. The two chain belts 30 , 40 are respectively provided with a reinforcing piece 32 , 42 on opposite sides of the respective bottom ends. The bottom stop 10 includes a socket 12, a pin 14 and an elastic piece 1238. The pin 14 is integrally injection-molded on the reinforcement piece 42 of the chain belt 40. The socket 12 is integrally injection-molded on the chain belt 30 relative to the pin 14. On the reinforcement sheet 32.

[0047] Please refer to figure 1 , the slider 20 includes an upper board 21 and a lower board 23 , a passageway 25 is formed between the upper board 21 and the lower board 23 .

[0048] Please refer to figure 1 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com