Design scheme for lamp tube body and lamp cap of light emitting diode (LED) fluorescent lamp

A technology of LED fluorescent lamps and design schemes, which is applied in the direction of lighting and heating equipment, semiconductor devices of light-emitting elements, light sources, etc., can solve problems such as time-consuming, reduce production progress, and increase labor costs, so as to reduce production costs, upgrade product quality, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Here are two embodiments to realize this patent:

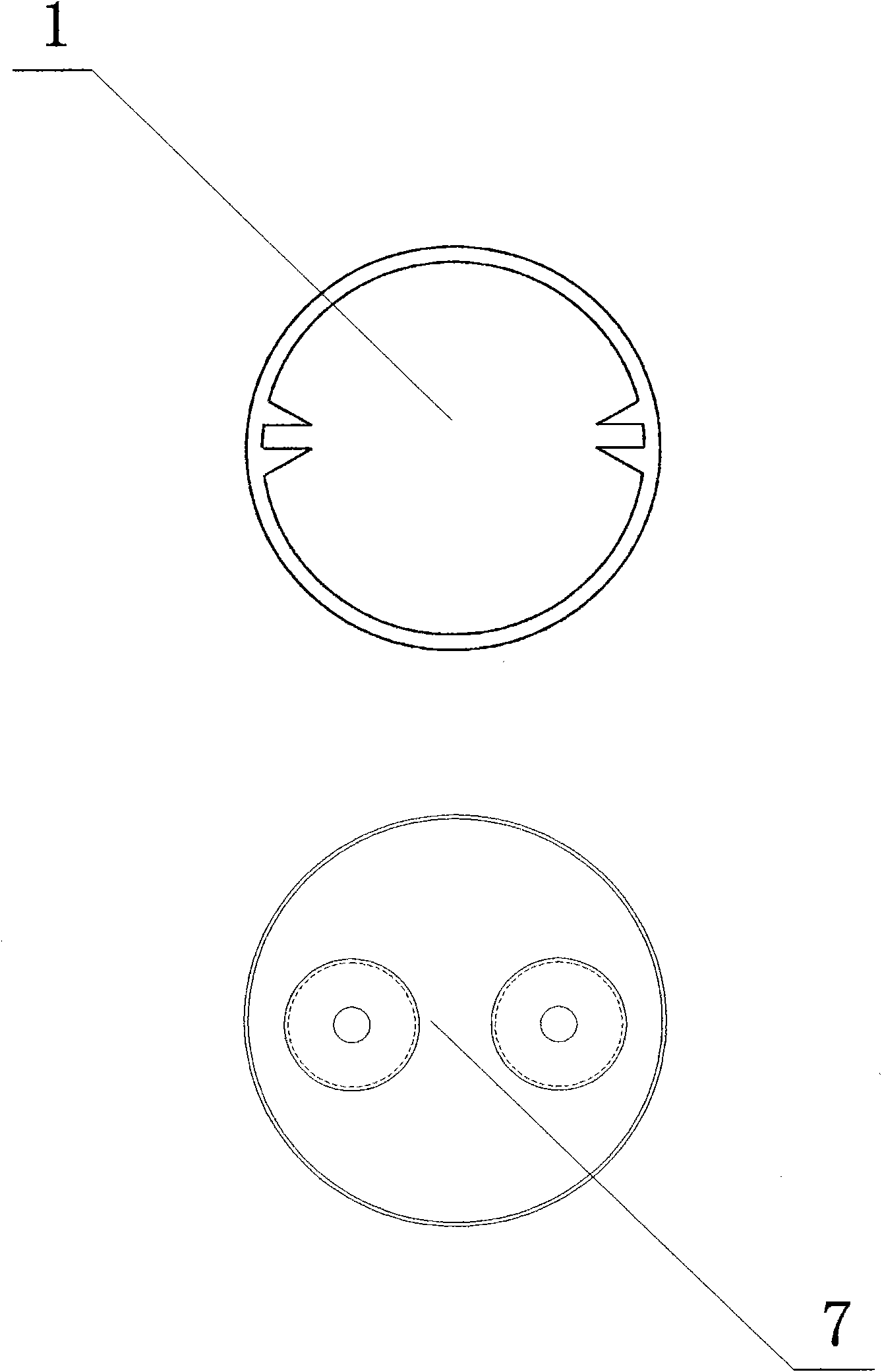

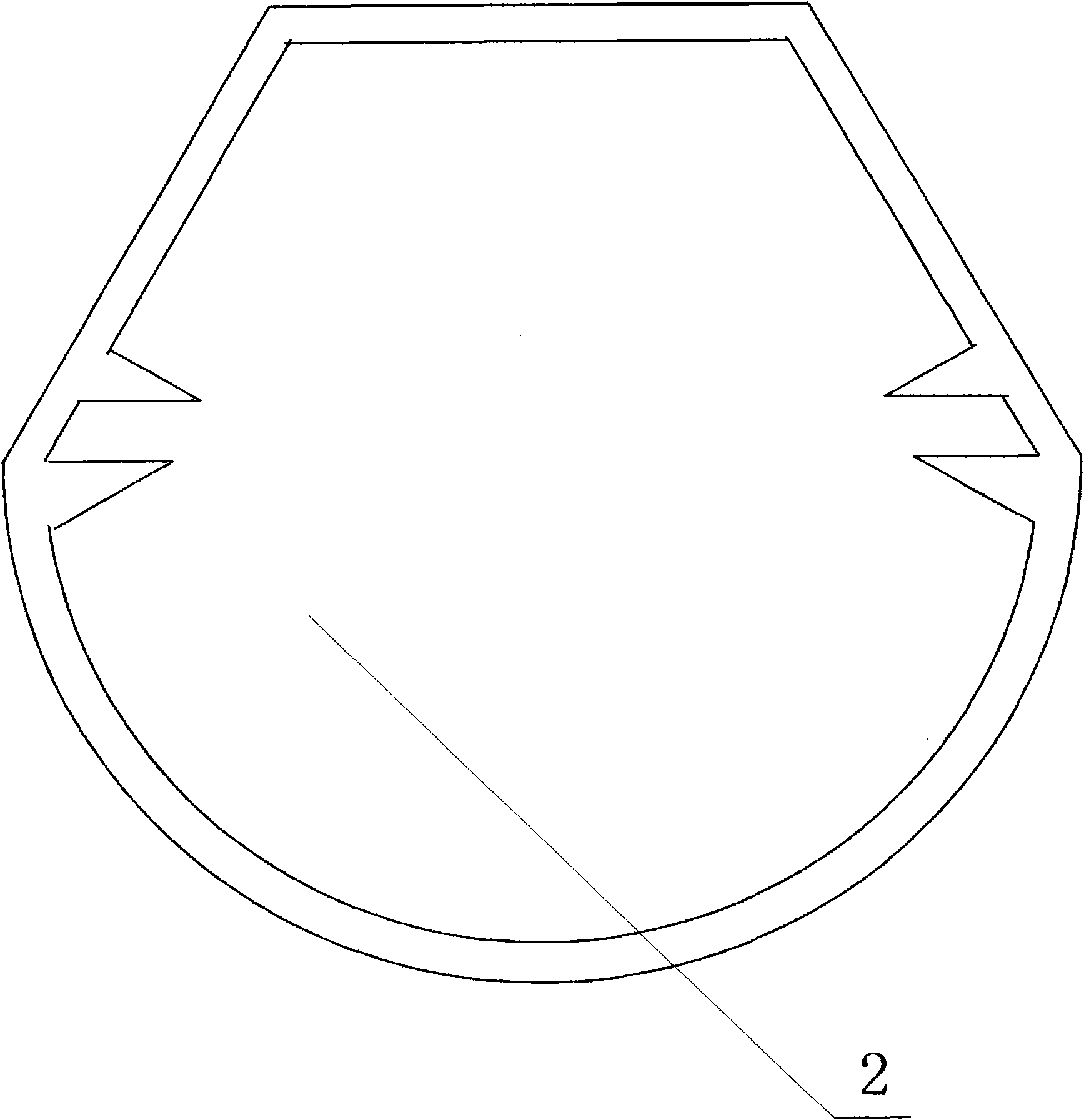

[0027] The first embodiment is to design an integrated special-shaped tube body (2) and a special-shaped lamp holder (6) matched with it, which are used as matching parts for the production of LED fluorescent lamps.

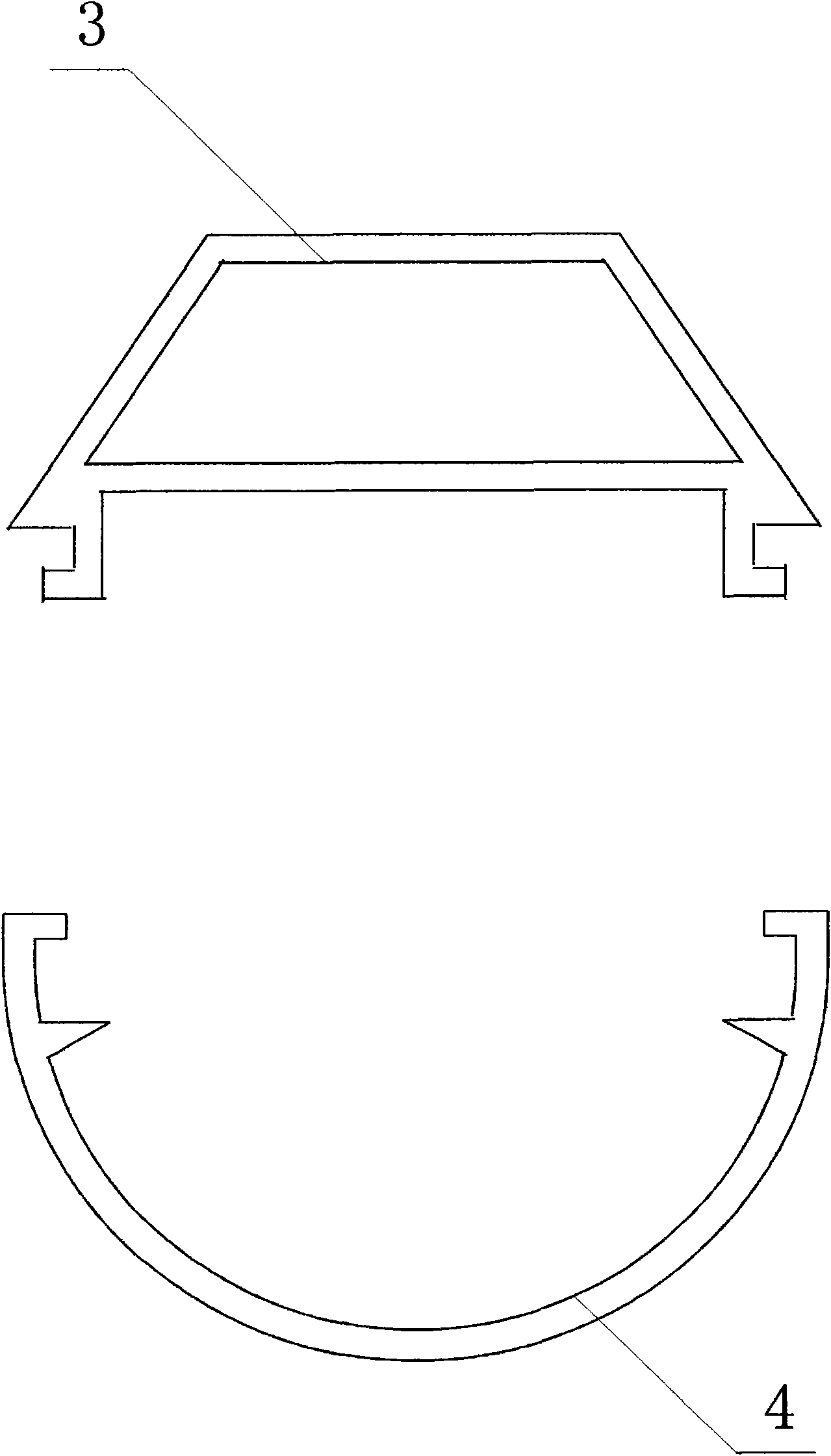

[0028] press figure 2 The cross-section of the integral special-shaped tube body (2) is shown to make a set of plastic die-casting molds, through which a certain length of integral special-shaped tube body (2) is die-casted with transparent PC plastic; Image 6 As shown, a set of stamping molds for metal parts is made, and the special-shaped lamp cap (6) is stamped out with thin aluminum skin through this set of molds, and the first embodiment is completed.

[0029] The second embodiment is to design a combined special-shaped tube body (5), the lamp holder still adopts the special-shaped lamp holder (6) as a supporting part in the production of LED fluorescent lamps. This set of accessories is used for LED fluo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com