Range hood with noise reduction structure

A range hood and noise reduction technology, applied in the field of range hoods with noise reduction structure, can solve the problem of high noise at the air inlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

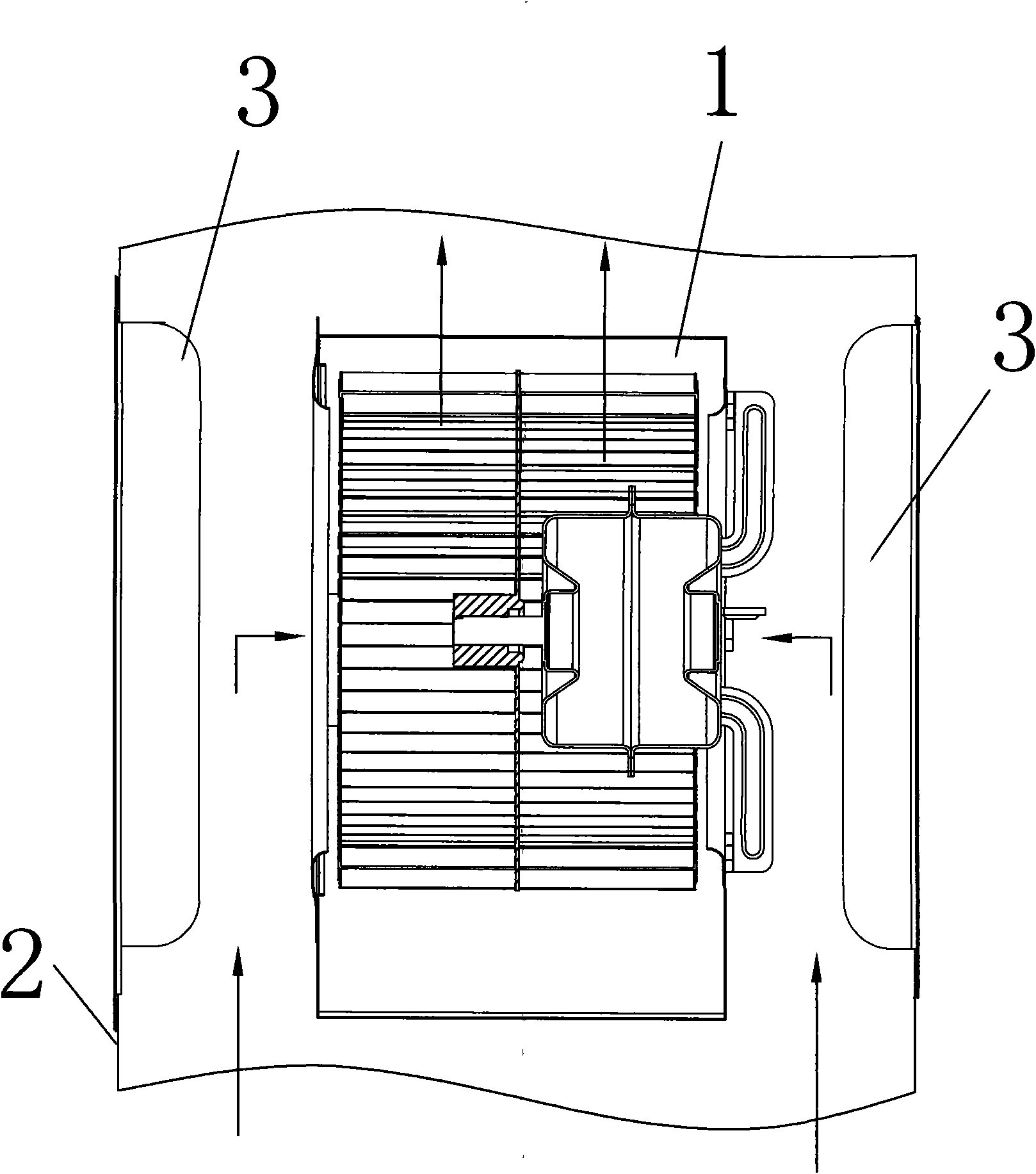

[0013] Embodiment: A range hood with a noise-reducing structure, which includes a centrifugal wind turbine set 1 and an air duct housing 2, the centrifugal wind turbine set 1 includes a wind wheel, a motor and a volute, and the centrifugal wind turbine The wheel set 1 is arranged in the air duct housing 2, and the air inlet of the air duct housing 2 is perpendicular to the air intake surface of the centrifugal wind wheel set 1. Based on the installation and use direction, the inner side of the air duct housing 2 is in line with the air intake surface. The two opposite sides parallel to the radial plane of the wheel are respectively provided with a rectifying plate 3, and the two rectifying plates 3 are respectively located on the two opposite sides of the air inlet of the centrifugal wind turbine group 1, and the two rectifying plates 3 are fixed on the sides of the air duct housing 2. On the inner side, oil fume can pass through the rectifying plate 3 to reach the air inlet sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com