Noise reduction device for front shaft forge piece feeding workshop section of intermediate frequency heating furnace

A technology for noise reduction and forging, applied in forging/pressing/hammer devices, metal processing equipment, furnaces, etc., can solve problems such as huge noise, and achieve the effects of reducing mechanical vibration, prolonging equipment service life, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

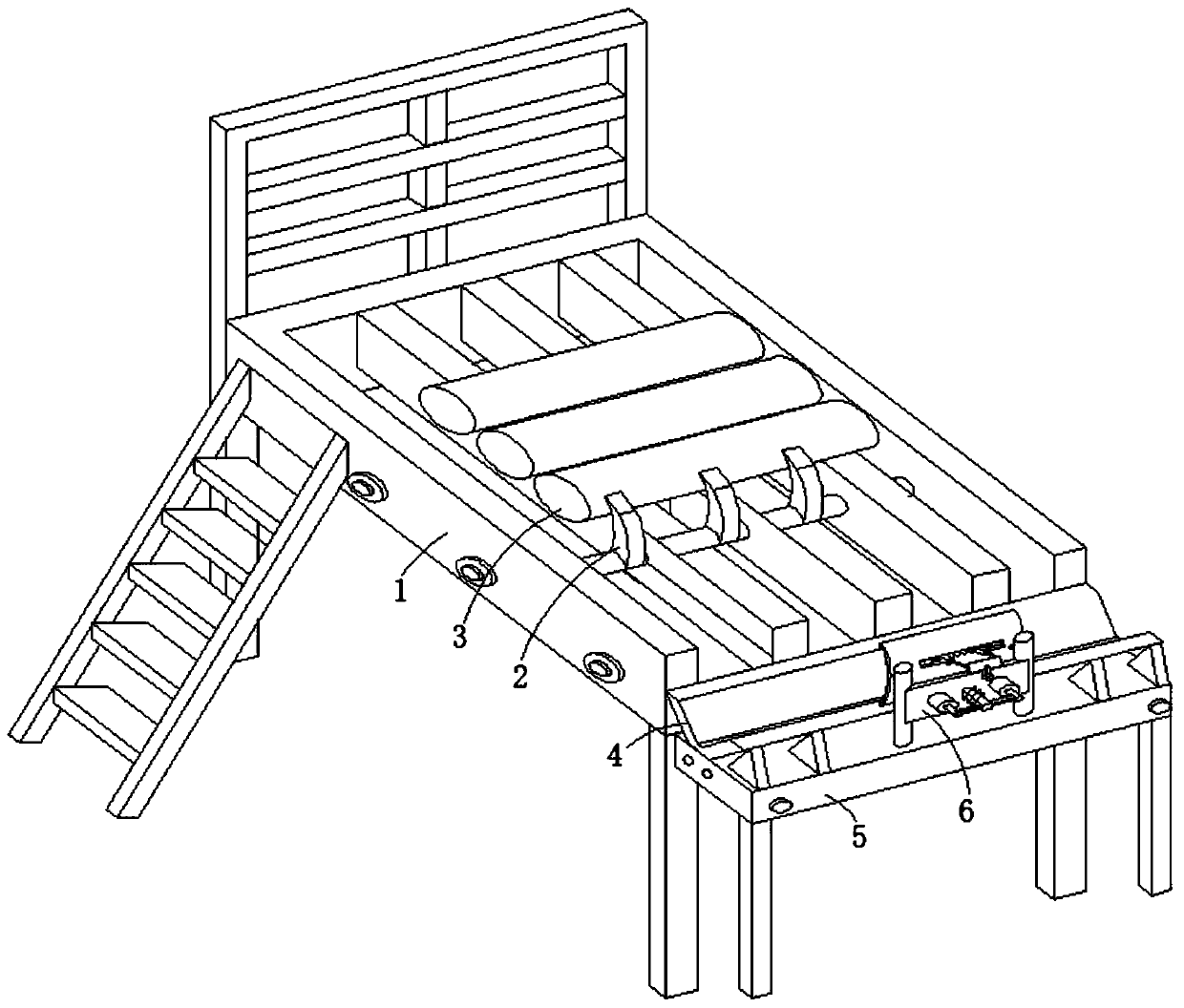

[0029] Attached below Figure 1-7 The present invention is further described with embodiment:

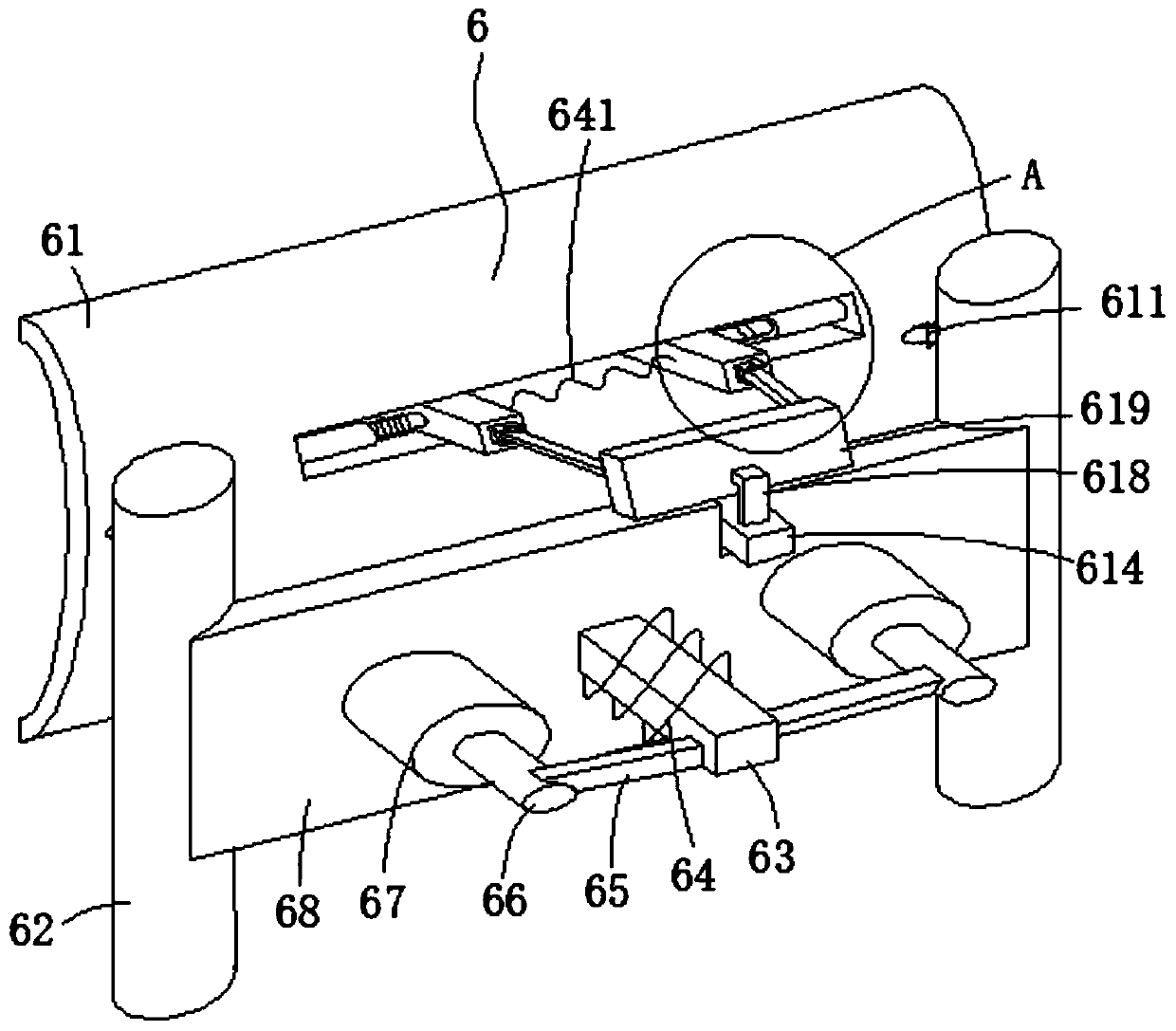

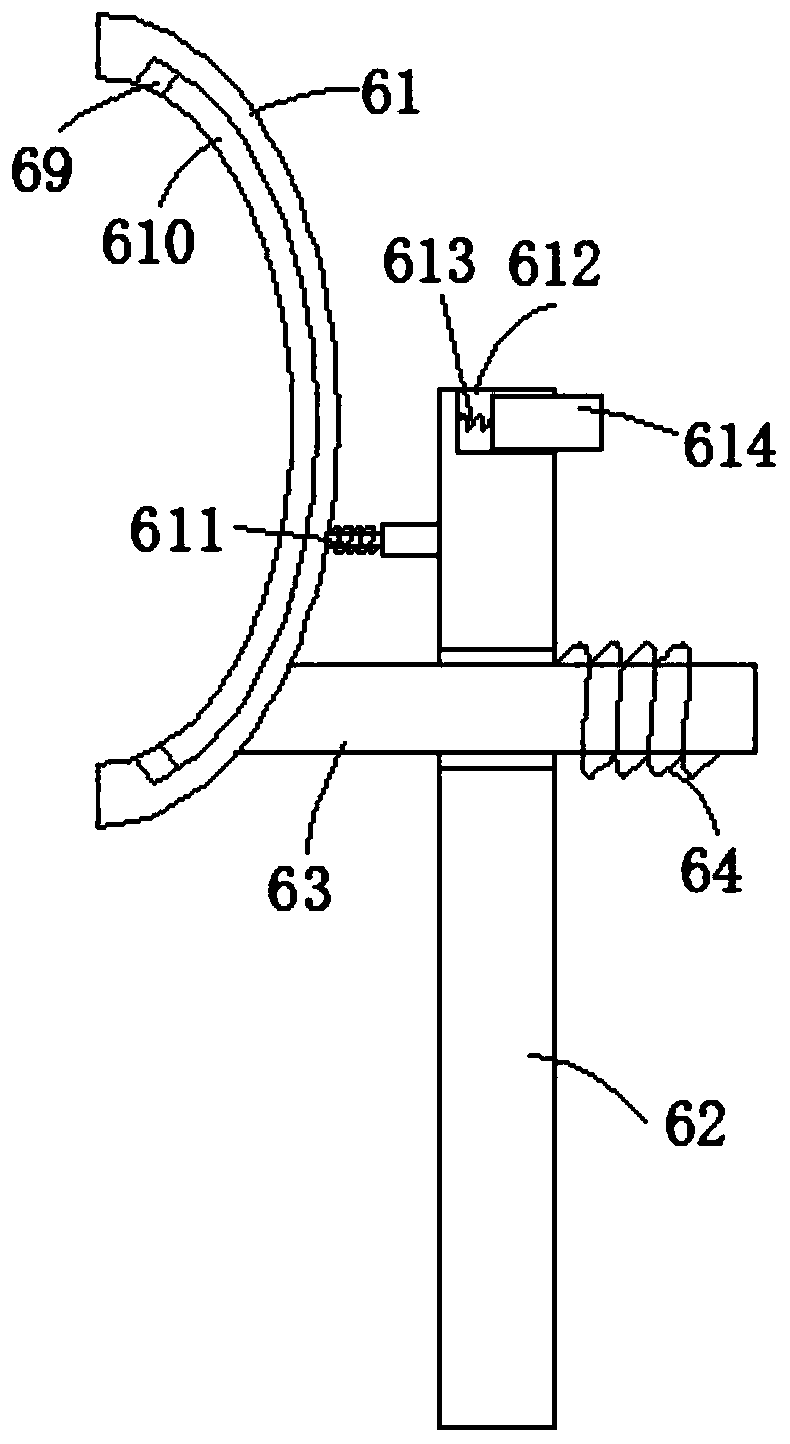

[0030] A noise reduction device for the loading section of the front shaft forging of an intermediate frequency heating furnace, comprising a transmission channel 4, a workbench 5 and a noise reduction device 6, the transmission channel 4 is set on the workbench 5, and the workbench 5 is connected to the placement bed 1, A stopper 2 is arranged on the placement bed 1, and a forging body 3 is arranged against the stopper 2, and the noise reduction device 6 is arranged on the workbench 5, and the noise reduction device 6 is arranged above the transmission channel 4, and the noise reduction device 6 Including the noise reduction plate 61 and the support column 62, the noise reduction plate 61 and the support column 62 are connected by the first elastic telescopic rod 611, and the rear end of the noise reduction plate 61 is fixedly provided with the first moving plate 63, the first movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com