Multi-core superfine coaxial cable CT connecting line cabling process

A technology of ultra-thin coaxial and coaxial cables, which is applied in the manufacture of coaxial cables, cable/conductor manufacturing, circuits, etc., and can solve the problems that limit the development of color CT data cable production technology, the complex structure of back-twisting equipment, and the difficulty in design, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

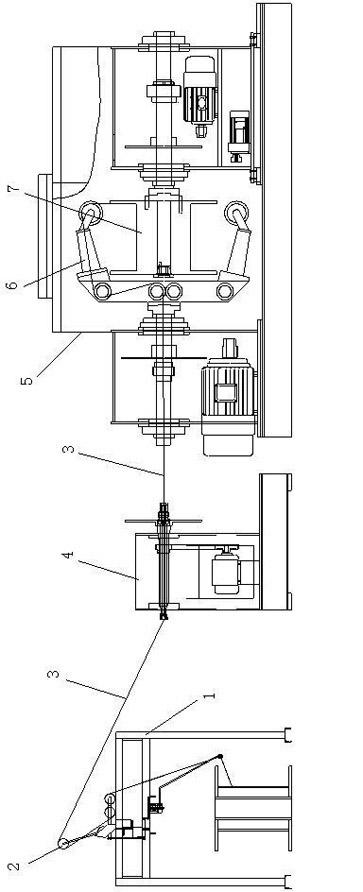

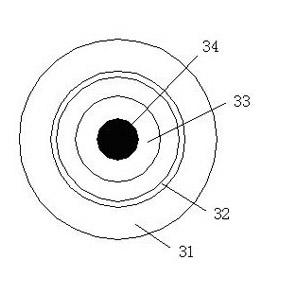

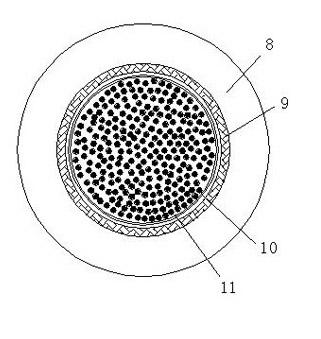

[0018] refer to figure 1 , figure 2 and image 3 , the CT connection wire forming process of the multi-core ultra-thin coaxial cable, the core wire 3 is released by the throwing type pay-off frame 1, and the core wire 3 produces S-direction or Z-direction torque during discharge, and the torque length is is the circumference of the core wire 3 on the pay-off shaft; the core wire 3 enters the wrapping machine 4 after coming out from the pay-off wheel 2 of the pay-off frame 1, and enters the single twisting machine 5 after passing through the wrapping machine 4 for twisting and winding. Cable take-up, the core wire 3 first enters the bow belt 6 for twisting, and the coaxial cable after twisting enters the take-up shaft 7 for cable take-up; the bow belt 6 is in the opposite direction of the torque generated when the core wire 3 is unwound Rotation, that is, if the core wire 3 produces S-direction torque when it is unwound, the bow belt 6 will rotate towards the Z direction; W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com