Power back-twisting pay-off machine

A technology of power and pay-off reel, which is applied in the direction of thin material processing, delivery of filamentous materials, transportation and packaging, etc., which can solve the problems of uneven force on the pay-off reel, lower production efficiency, high operating noise, etc., and achieve wear and tear Small size, improved production efficiency, and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe in detail the technical content, structural features, and achieved effects of the present invention, detailed descriptions are given below with reference to the embodiments and the accompanying drawings.

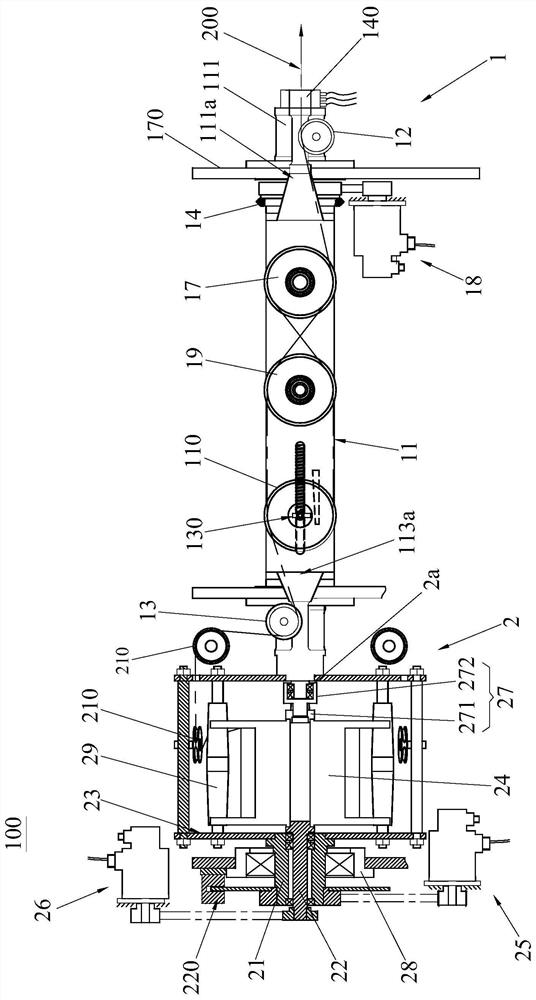

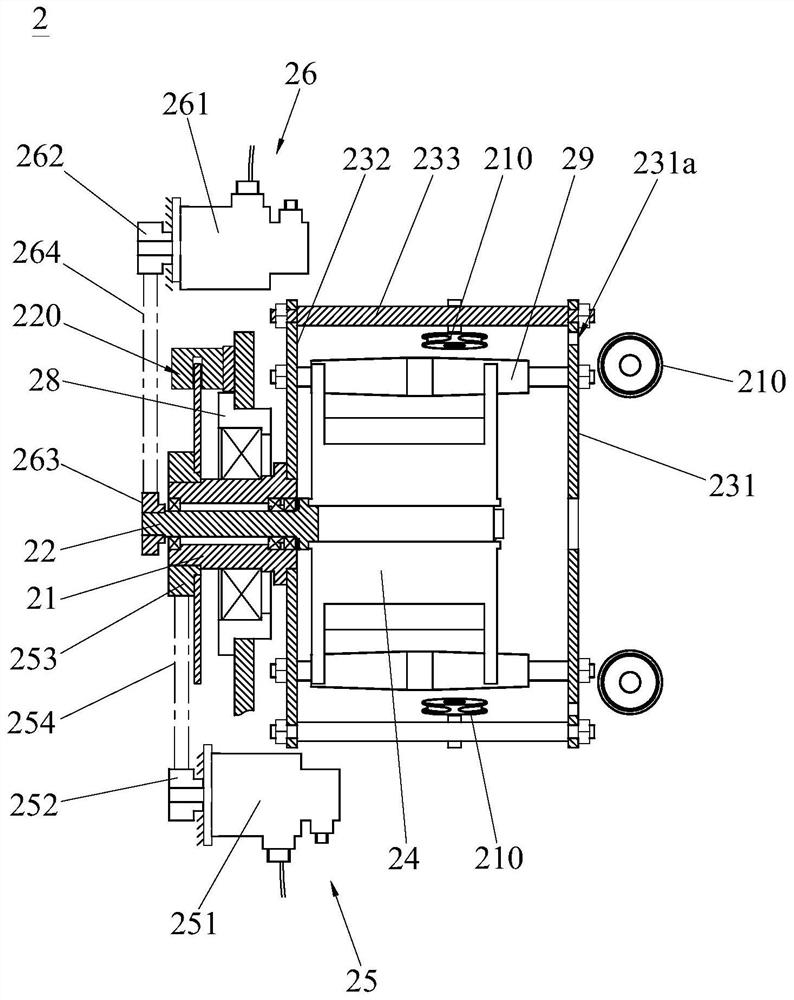

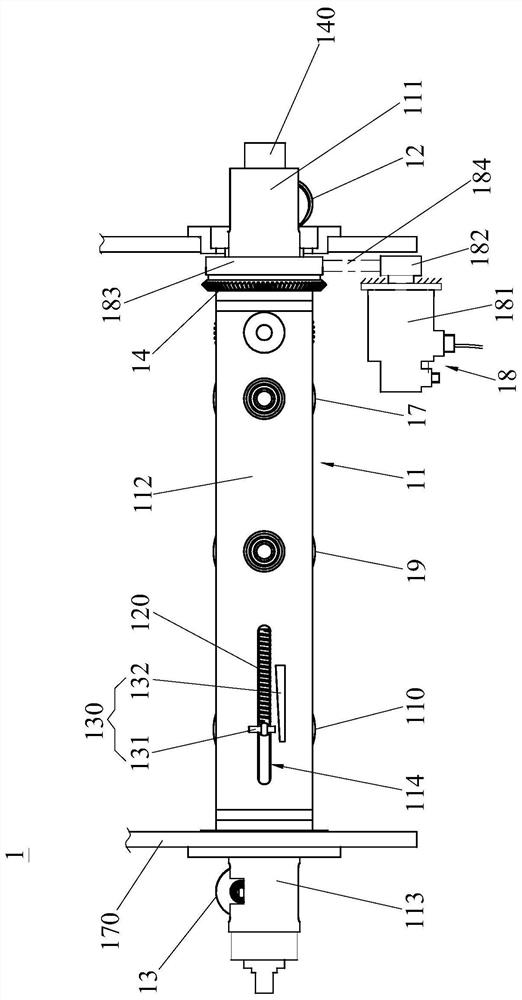

[0023] like Figure 1 to Figure 2 As shown, the power untwisting pay-off machine 100 of the present invention is suitable for untwisting and paying off the core wire 200, and it includes a pay-off tension mechanism 1 and a pay-off mechanism 2; the pay-off mechanism 2 includes a main shaft 21, a pay-off shaft 22. Turntable 23, pay-off reel 24, turntable drive mechanism 25 and reel drive mechanism 26, the main shaft 21 is coaxially and rotatably sleeved outside the pay-off reel 22; The center is detachably connected to one end of the pay-off shaft 22, and the center of the other side of the pay-off reel 24 is coaxial and rotatable with the rotation center axis of the pay-off tension mechanism 1 through a bearing 2a. The center of one side of the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com