Vibratory feeding machine

A technology of vibrating feeder and feeding trough, which is applied in vibrating conveyors, conveyors, transportation and packaging, etc., which can solve the problems of large equipment volume and weight, short service life, and large motor power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

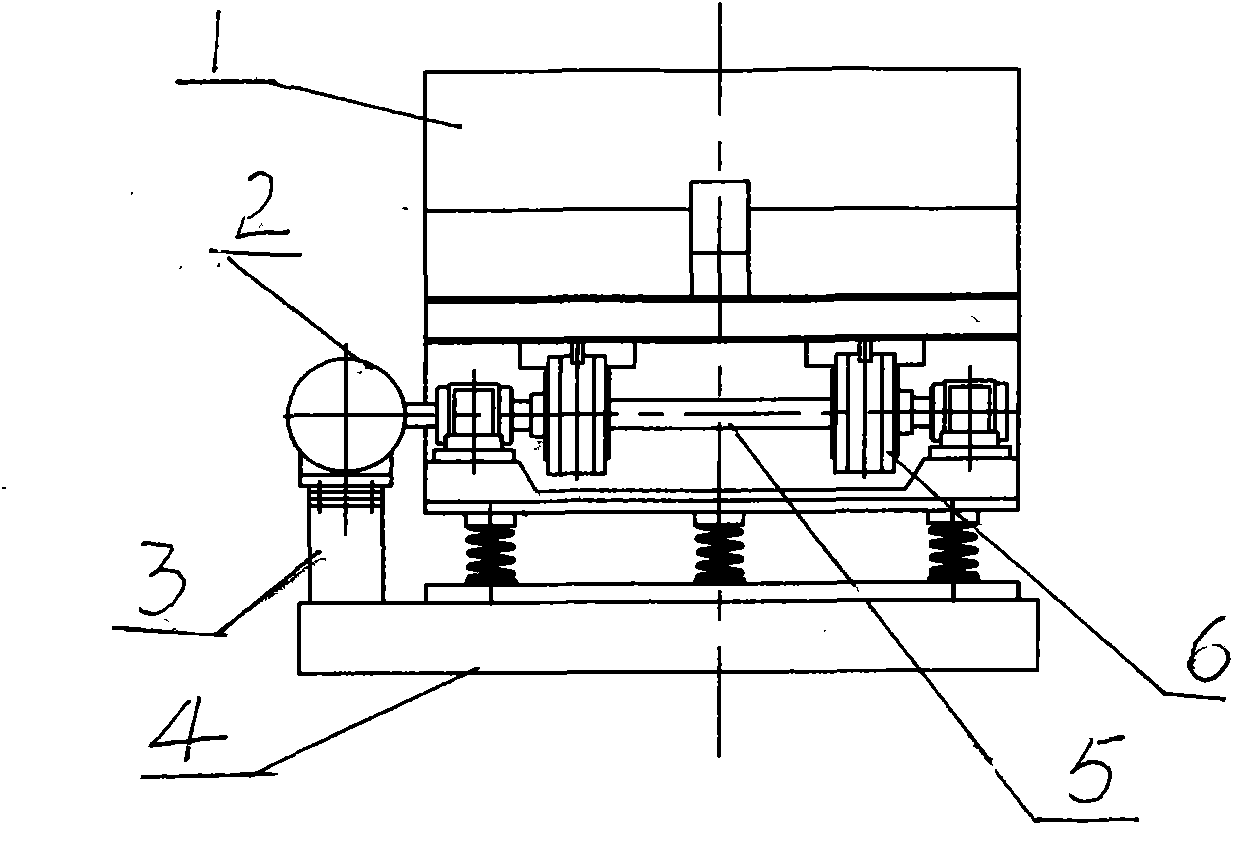

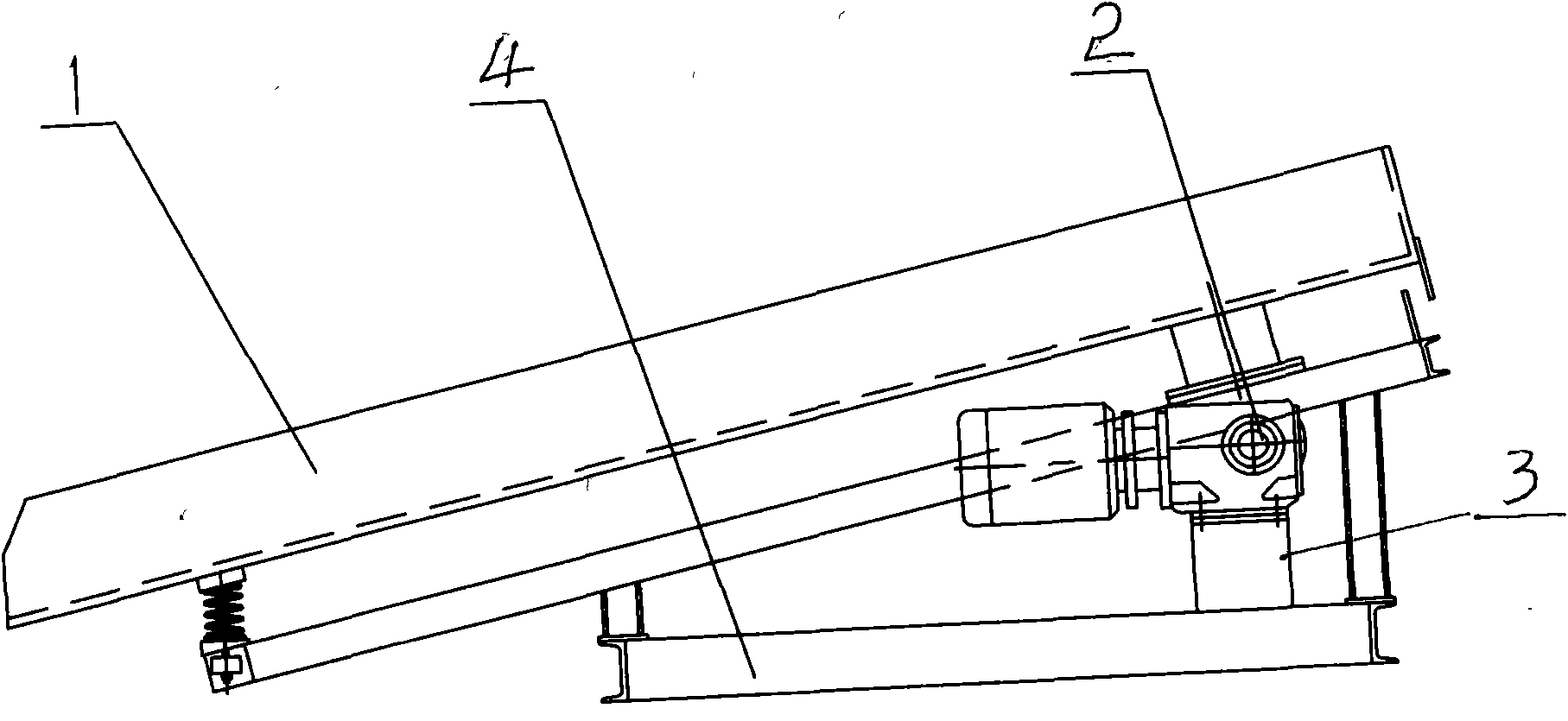

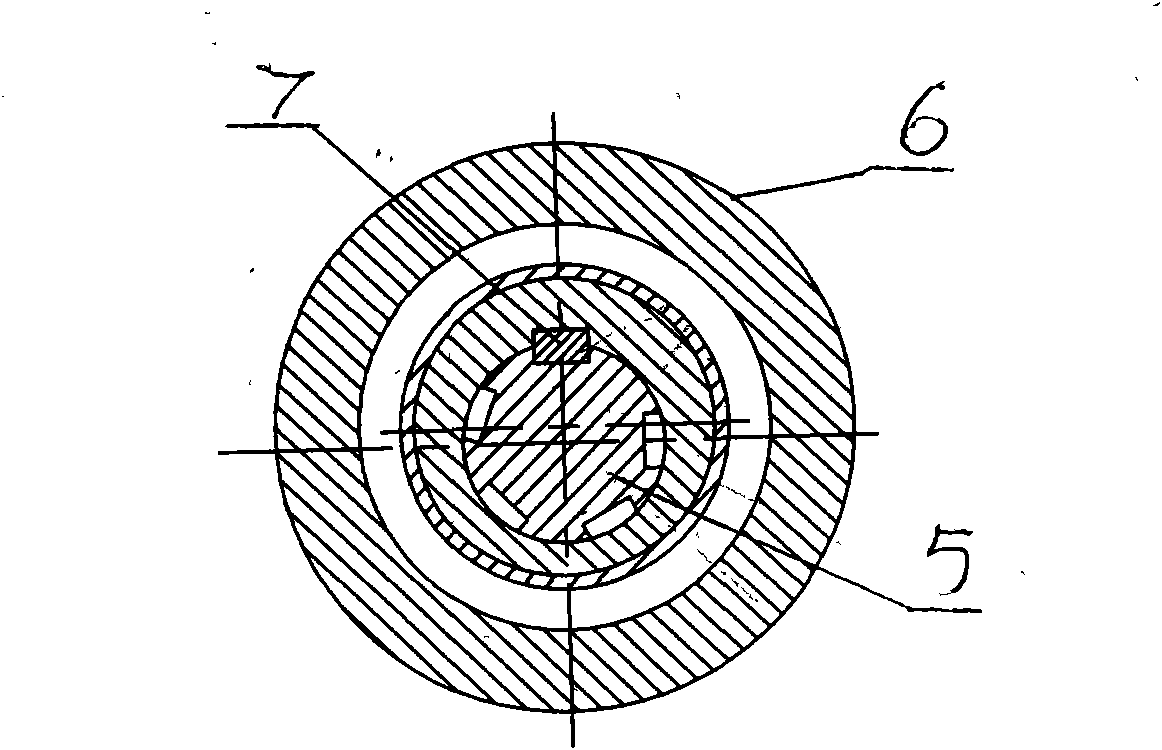

[0006] Embodiments are described in detail with reference to the accompanying drawings. The present invention is an improvement on the prior art, and it includes a feeding trough 1 and its vibration-damping frame 4. The improvement is that a motor base 3 is provided on one side of the feeding trough, and a speed reducer is installed on the motor base. Machine 2, a spline shaft 5 is installed on both sides of the vibration damping frame at the bottom of the feeding trough through the bearing seat, and two vibrators 6 are symmetrically installed on the spline shaft, and one end of the spline shaft is connected to the reducer shaft on (such as figure 1 shown). During use, by adjusting the installation orientation of the key 7 on the spline shaft, the size of the amplitude can be adjusted conveniently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com