Quantitative filling device

A technology for filling equipment and measuring cups, which is applied in the field of equipment for quantitatively filling mercury sphygmomanometers with mercury, can solve problems such as low production efficiency, outdated processes, mercury poisoning, etc., so as to improve production efficiency, realize non-contact operation, reduce The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

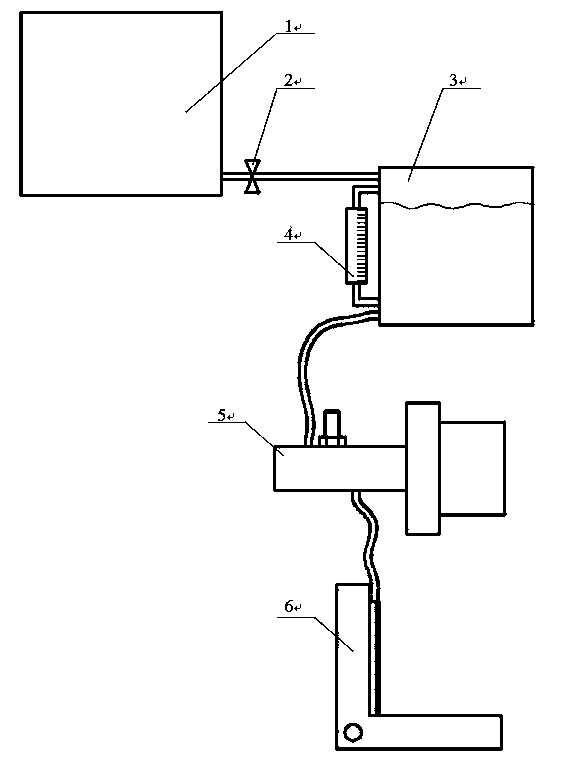

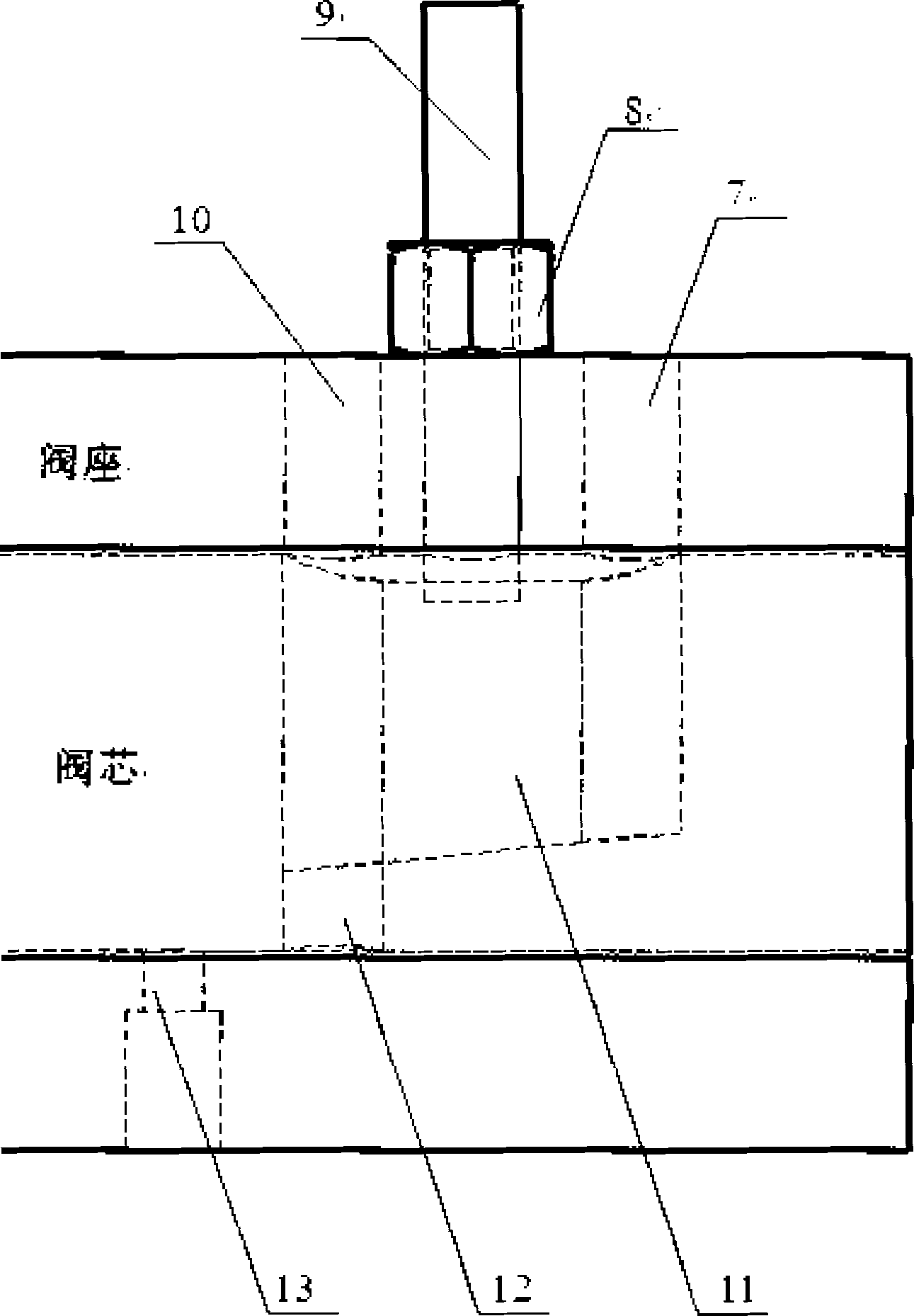

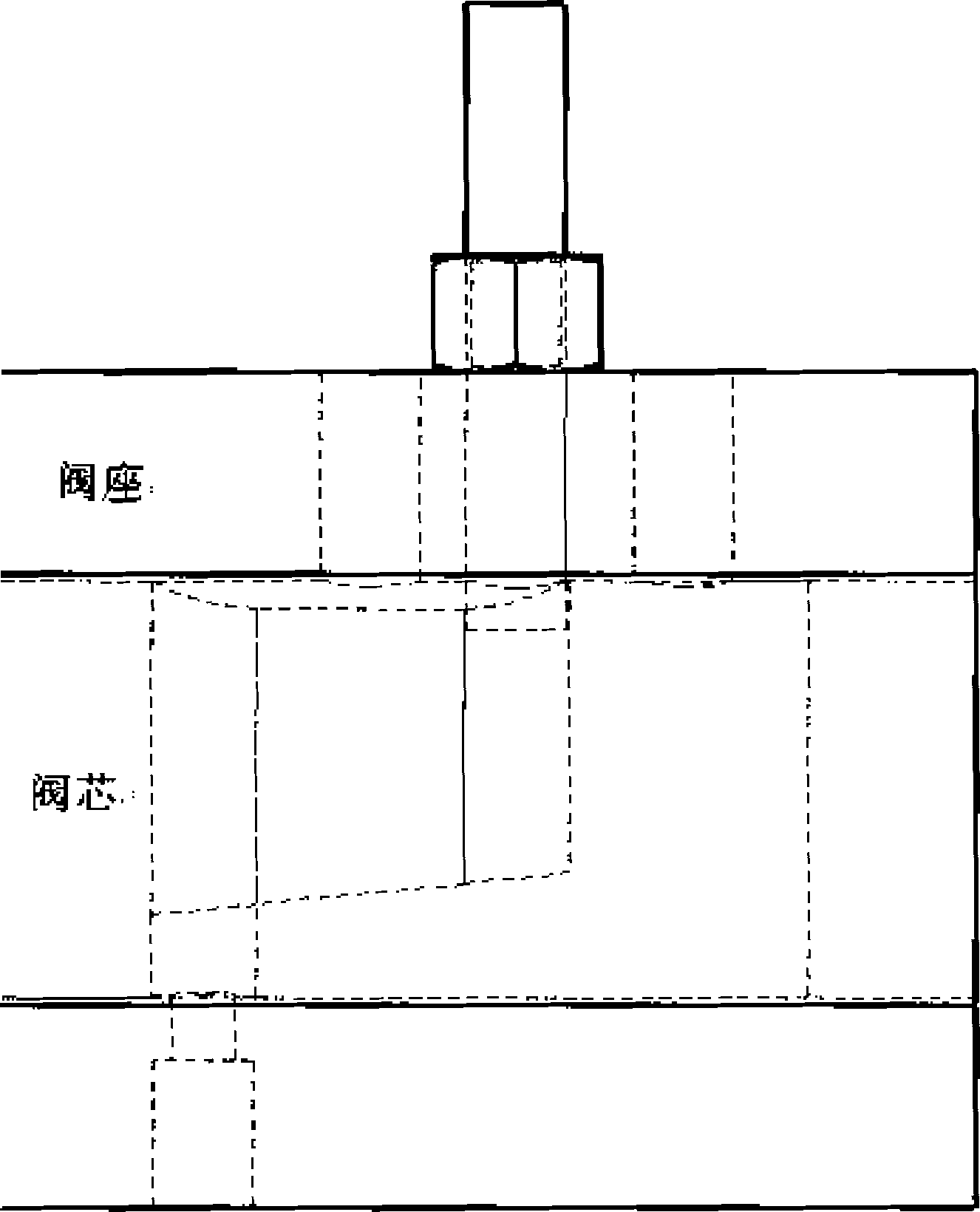

[0010] Such as figure 1 As shown, a mercury sphygmomanometer filling equipment includes a lead bucket 1, a switch 2, a mercury cup 3, a scale 4, and a filling device 5. Mercury can react with various metals, but not with lead and plastics, so the materials used in the present invention are lead and plastics. The lead barrel 1 is used to store mercury during transportation, and generally has a relatively large volume. Lead the lead barrel 1 to an outlet, and there is a switch 2 at the outlet, and the mercury flows into the mercury cup 3 through a plastic tube. The side of the mercury cup 3 is equipped with A scale meter 4, through which the amount of mercury in the mercury cup 3 can be known. There is an opening at the lower end of the mercury cup 3, which is connected to the mercury inlet hole 7 of the valve seat in the filling device 5 through a rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com