Safe and explosion-proof pyrotechnic composition milling device

A pyrotechnic agent and safety technology, which is applied in the field of pyrotechnic agent grinding devices, can solve the problems of safety hazards, no grinding samples, sieving safety system, no safety hazards that can eliminate pyrotechnic agents, etc., and achieves the effect of simple structure and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

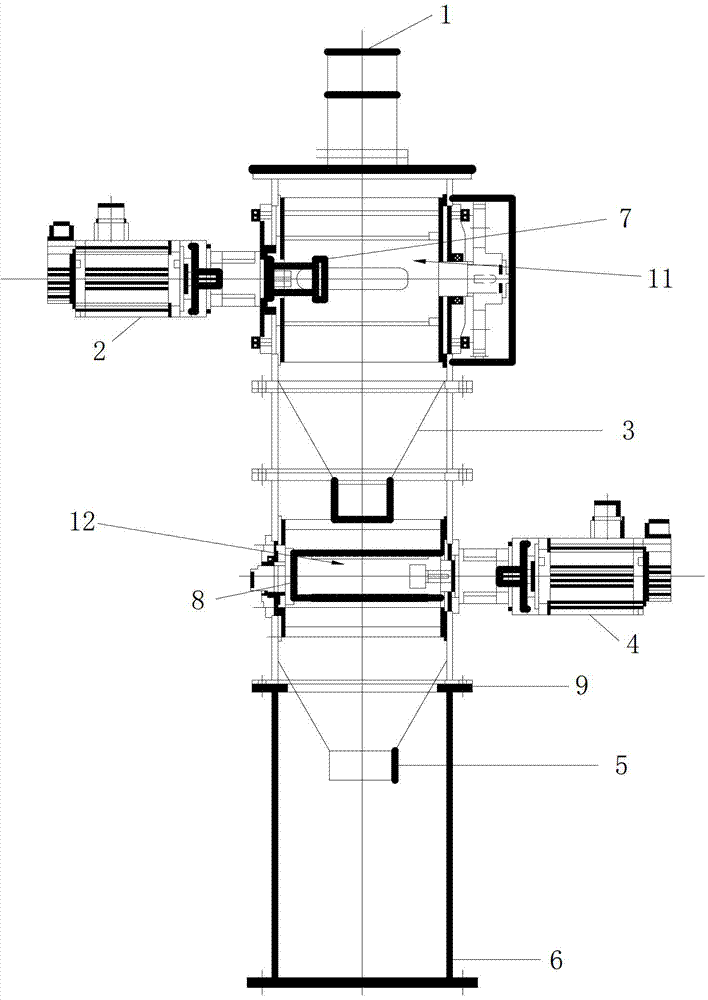

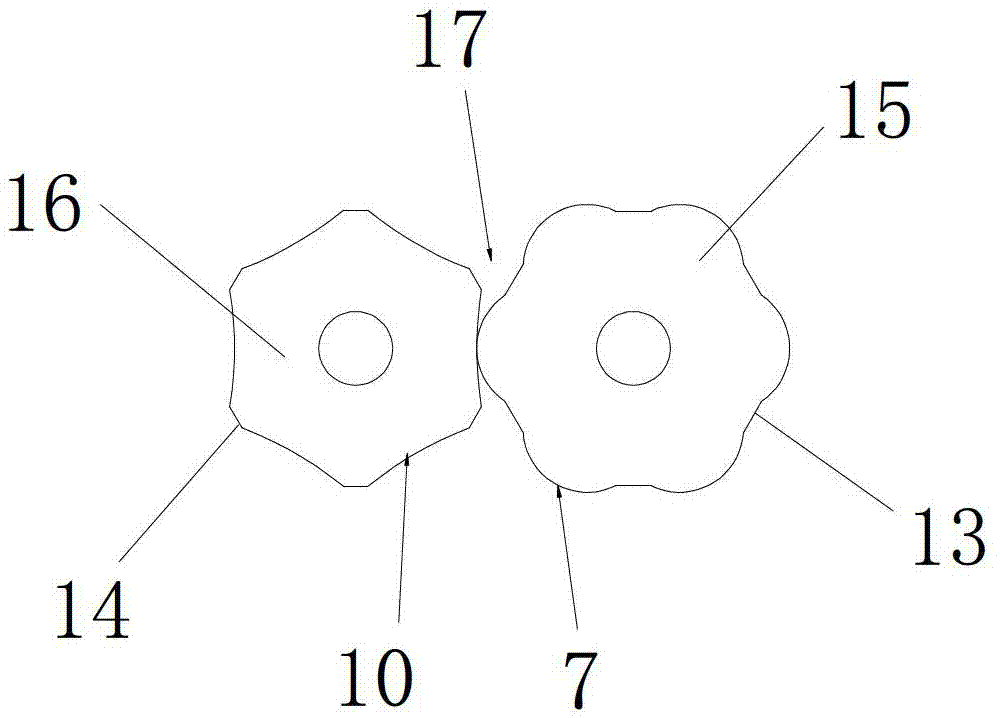

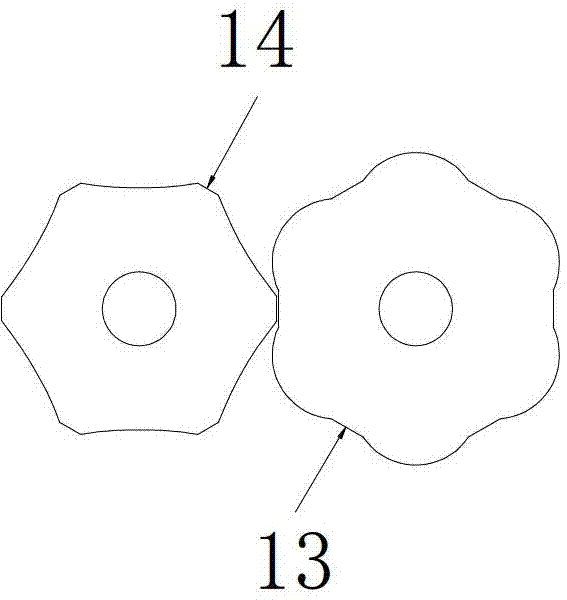

[0016] Below in conjunction with accompanying drawing, the present invention will be further described:

[0017] As shown in the drawings, the frame 6 is sequentially provided with an automatic feeding mechanism 1, a primary crushing system 11, a secondary crushing system 12, a vibrating screen 9, and a material collection box 5 from the top to the bottom; the primary crushing system 11 Between the secondary crushing system 12, there is an excessive connection seat 3 with a blanking channel, and the primary crushing system 11 and the secondary crushing system 12 are composed of an engaged active copper roller 15, a passive copper roller 16 and a driving device. constitute.

[0018] The driving device is composed of a hydraulic motor, a transmission wheel set, and a pair of transmission pairs. A pair of transmission pairs such as two meshed gears are respectively installed on the end shafts of the driving copper roller 15 and the passive copper roller 16 to realize the active c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com