Belt winding aid and method for aiding in cold steel strip winding by using same

A technology of a coiler and a belt, applied in the field of strip steel coiling, can solve problems such as affecting the quality of finished products, fluctuation of coiling tension, uneven edge of steel coil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

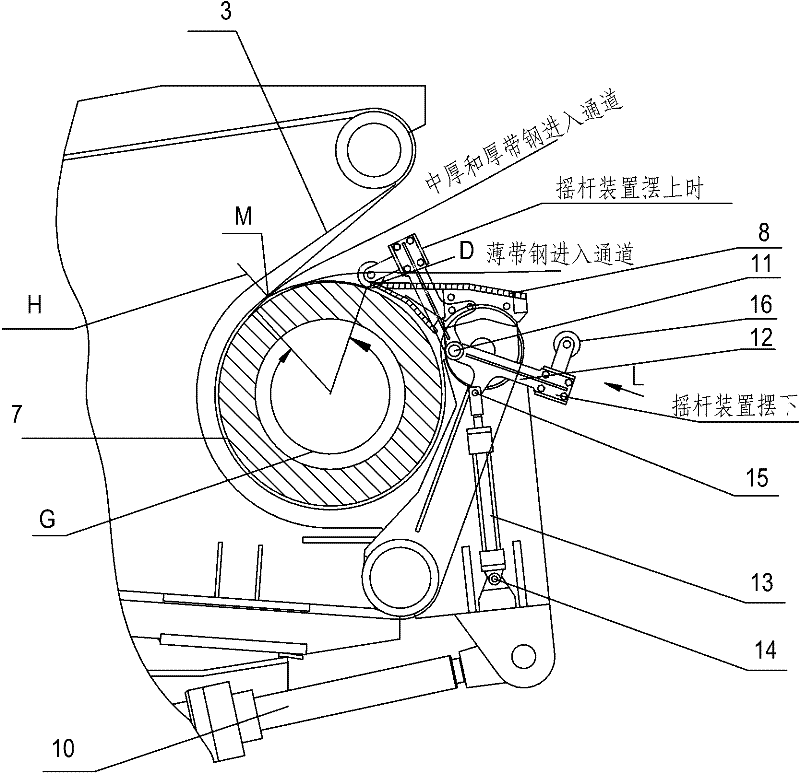

[0026] The present invention will be further described below in conjunction with the accompanying drawings and various embodiments.

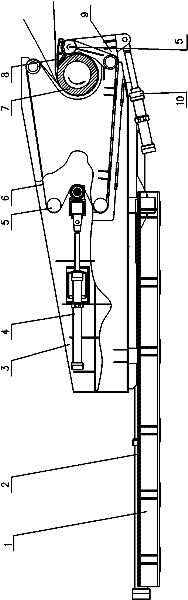

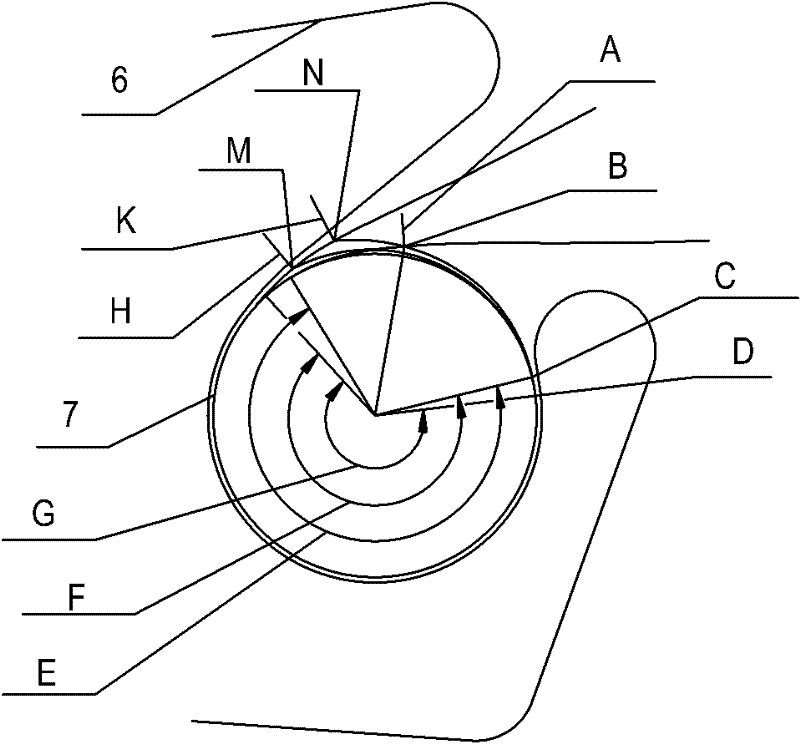

[0027] The structure of the main part of the belt winding aid of the present invention is as image 3 As shown, the structure of the omitted part is the same as figure 1 The same: mainly including trolley 3, base 1, endless belt 6, rotating arm 9, first hydraulic cylinder 2, second hydraulic cylinder 10, guide plate 8, third hydraulic cylinder 4, wherein trolley 3 is connected to first hydraulic cylinder 2 and Under the push of the first hydraulic cylinder 2, it can slide horizontally along the base 1 to the reel 7 of the coiler, and a plurality of pulleys 5 are installed on the trolley 3; Arm 9, the pivoting arm 9 is movably connected with the second hydraulic cylinder 10 and can rotate upwards under the promotion of the second hydraulic cylinder 10; the guide plate 8 is arranged above the pivoting arm 9 and keeps a fixed distance with the coi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com