Shunt device of heater

A technology of a shunt device and a heater, applied in the field of dyeing, can solve the problems of increasing nozzle pressure difference, reducing the color difference of the fabric, and being unbalanced, and achieving the effect of reducing the pressure difference and reducing the color difference of the fabric.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

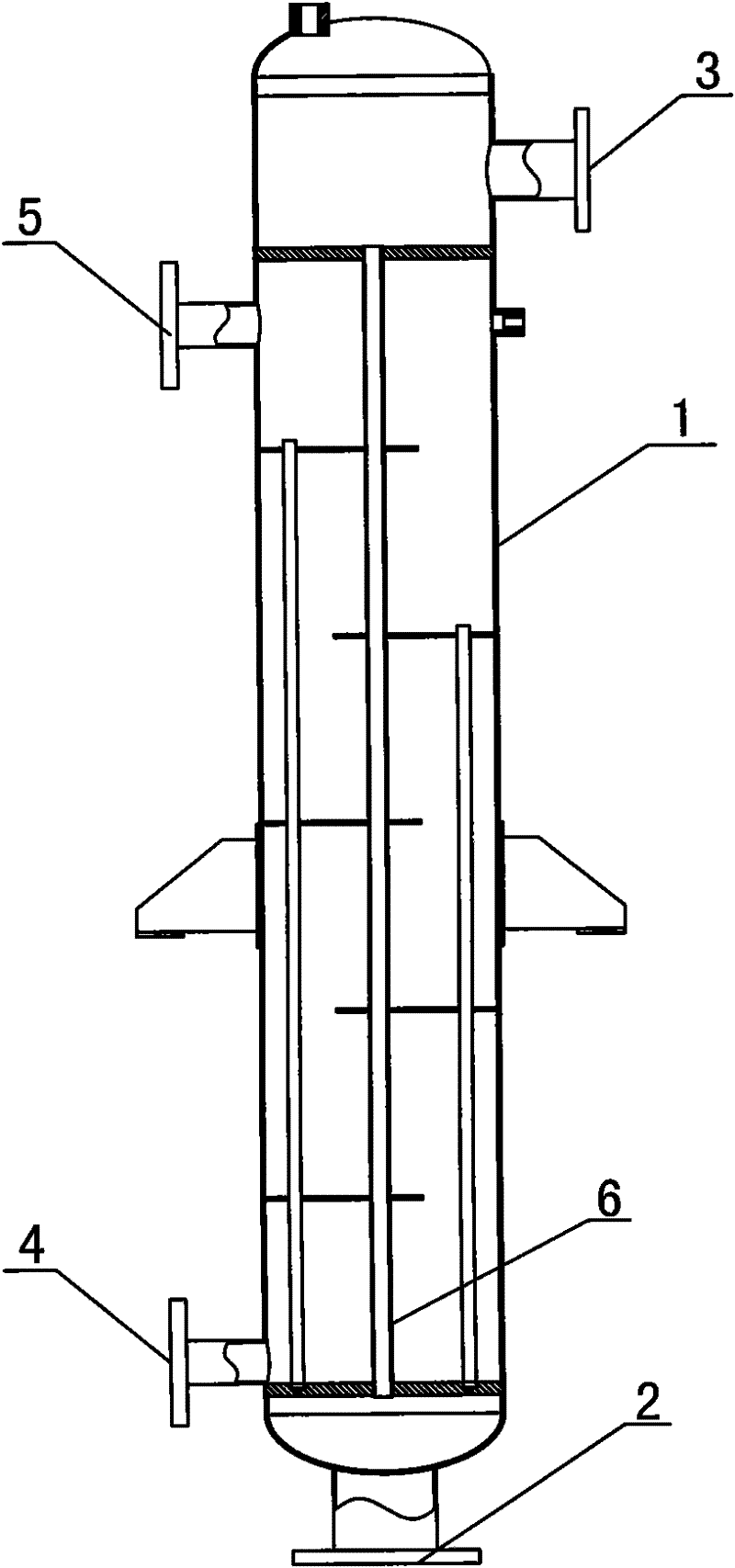

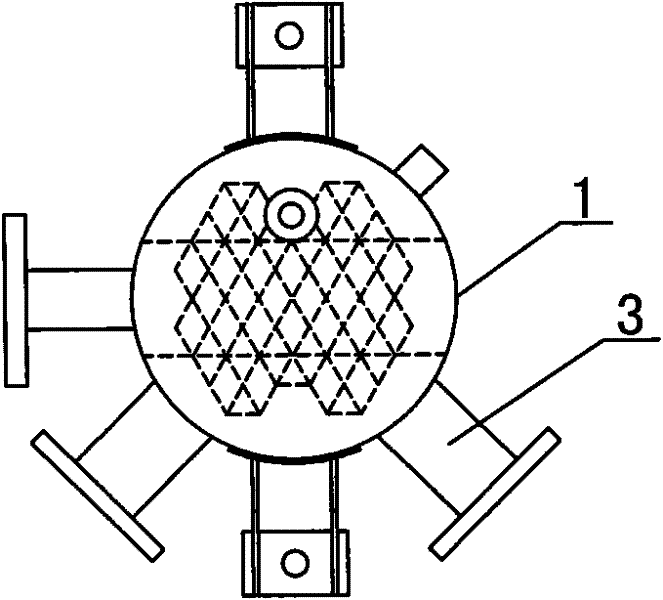

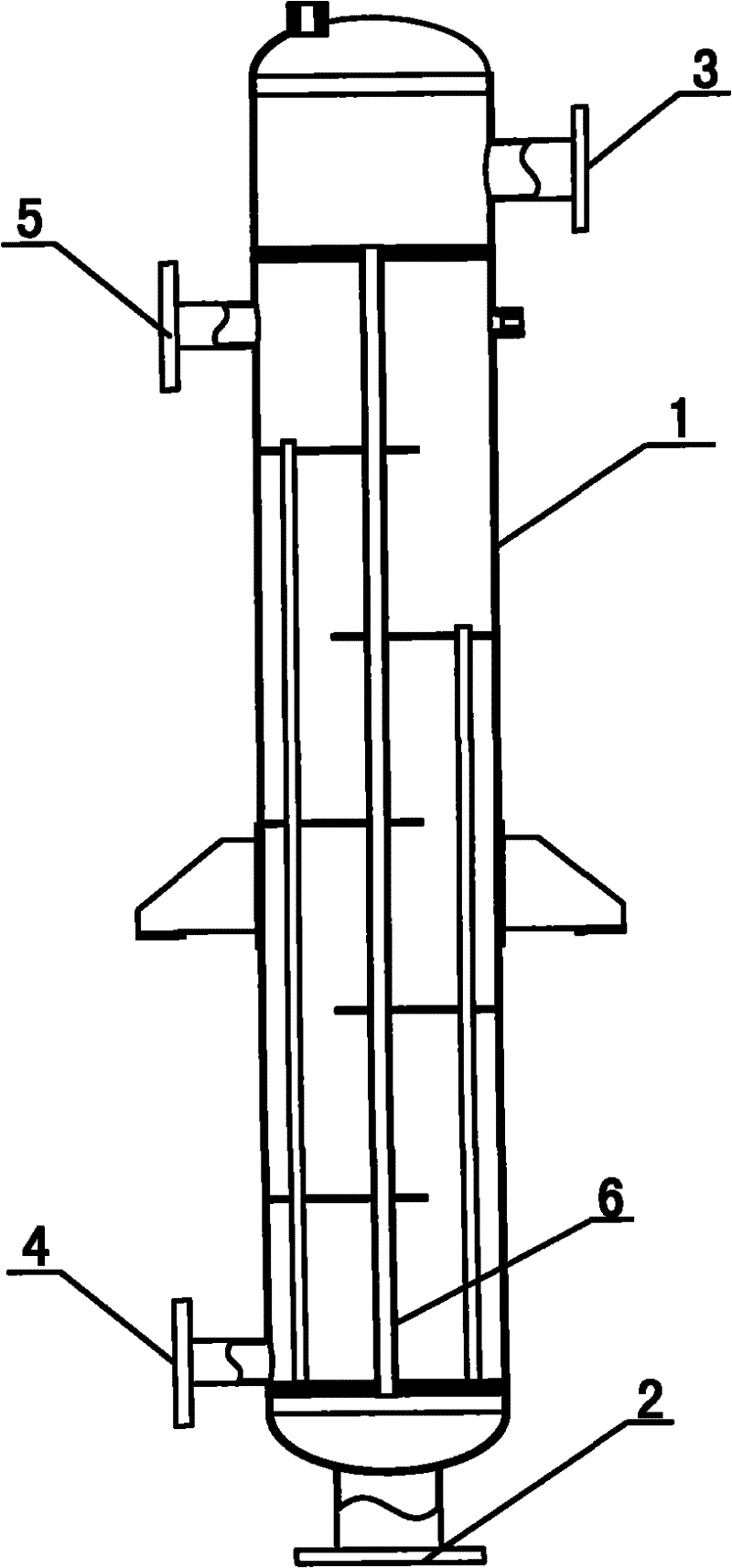

[0012] Such as Figure 1-2 As shown, the heater splitter device of the present invention includes a separate liquid distribution pipeline 6 inside the liquid separation cavity 1, and the dye liquid inlet 2 and the dye liquid inlet 2 are respectively provided at the two ends of the liquid separation cavity 1. Outlet 3, a condensed water outlet 4 is provided on the outside of the cavity located at the dye liquor inlet 2, and a steam inlet 5 is provided on the outside of the cavity located at the dye liquor outlet 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com