Patents

Literature

31results about How to "Reduce stress differential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

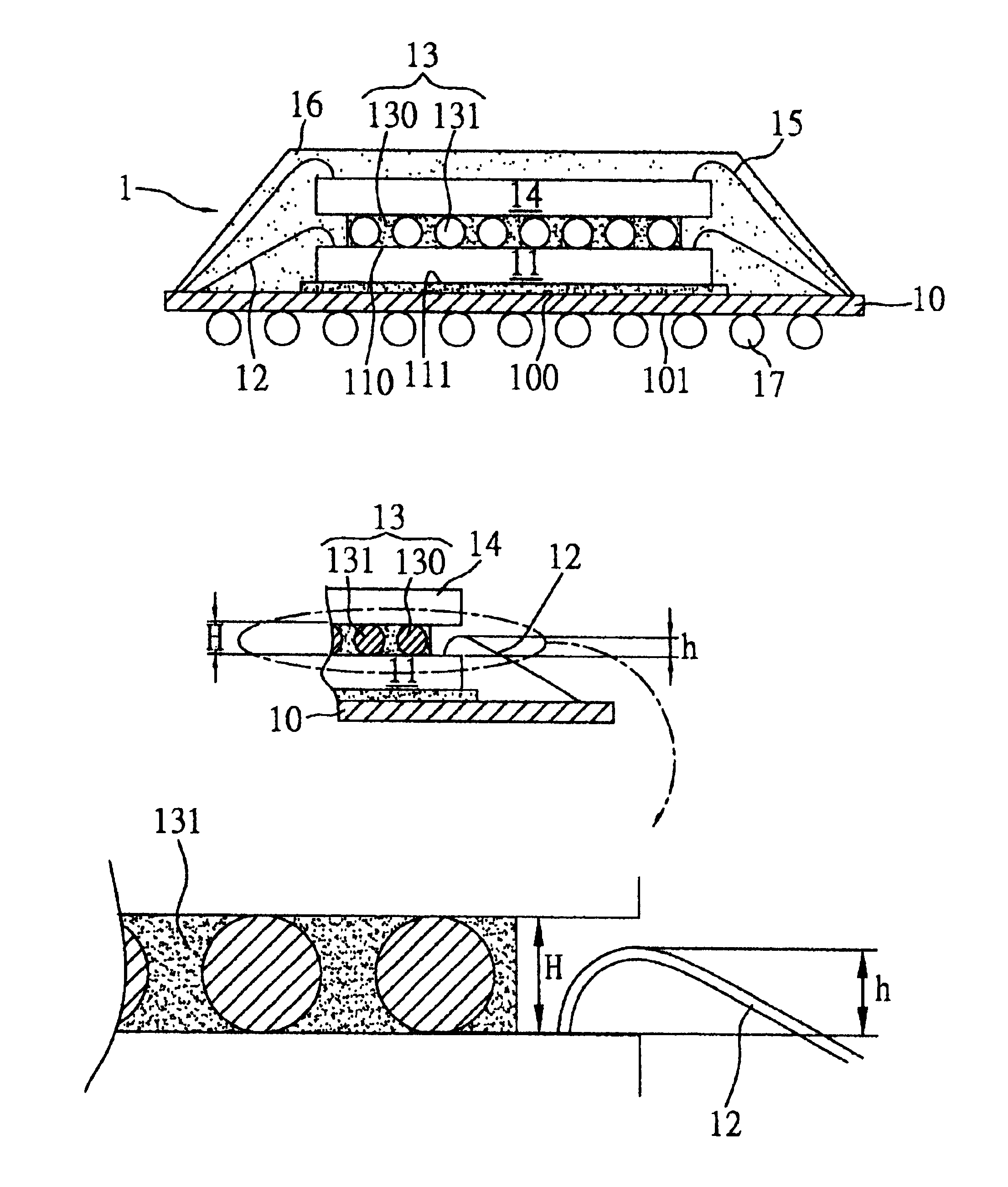

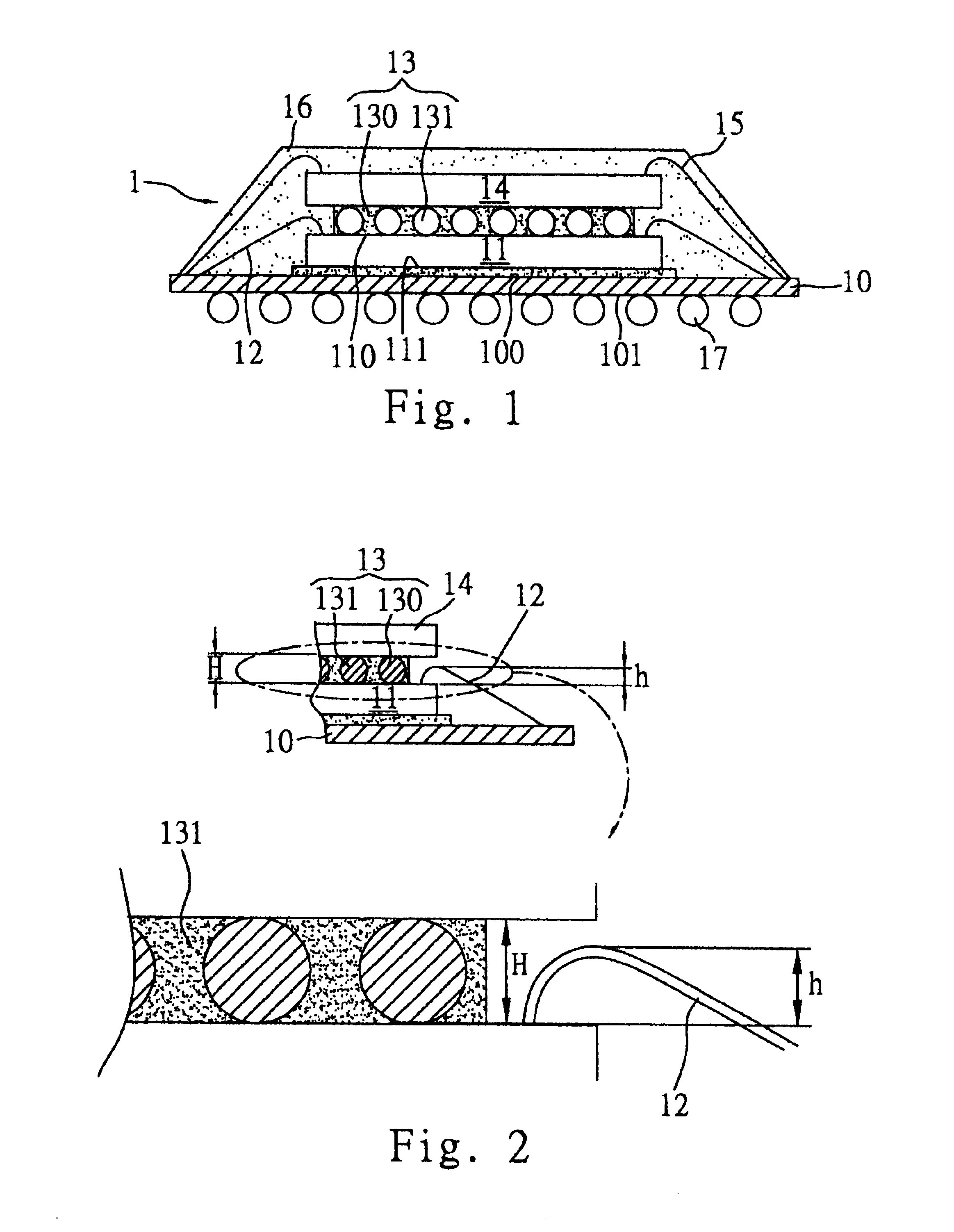

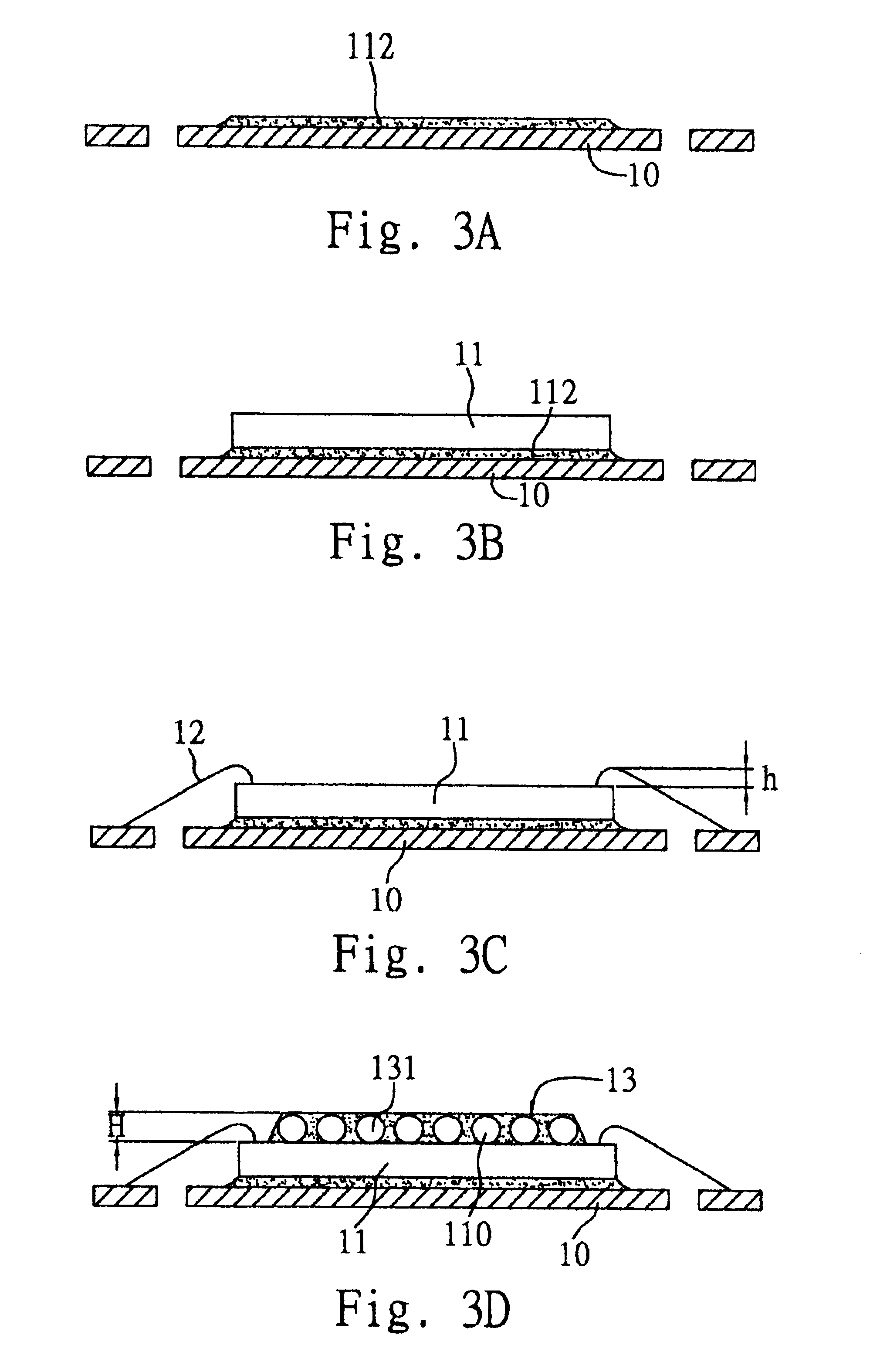

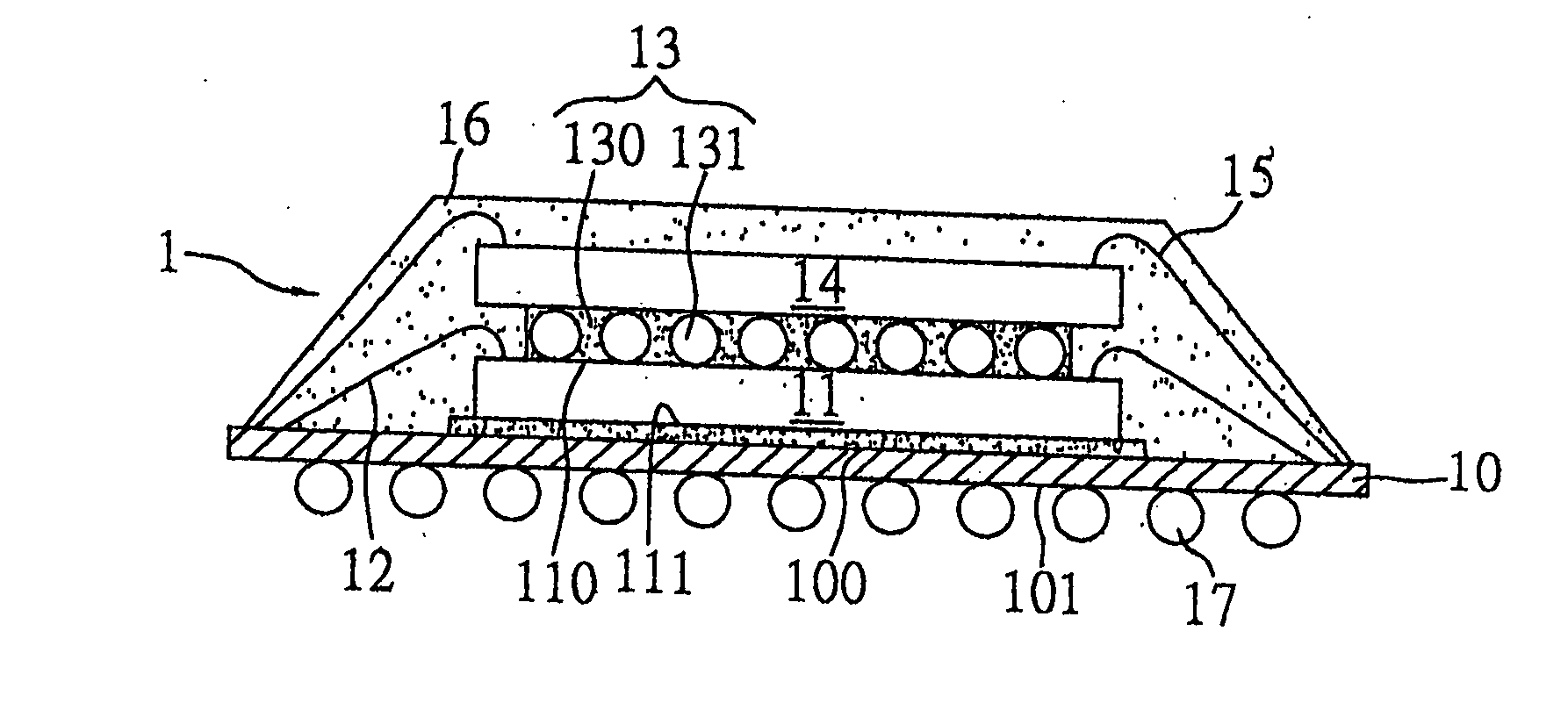

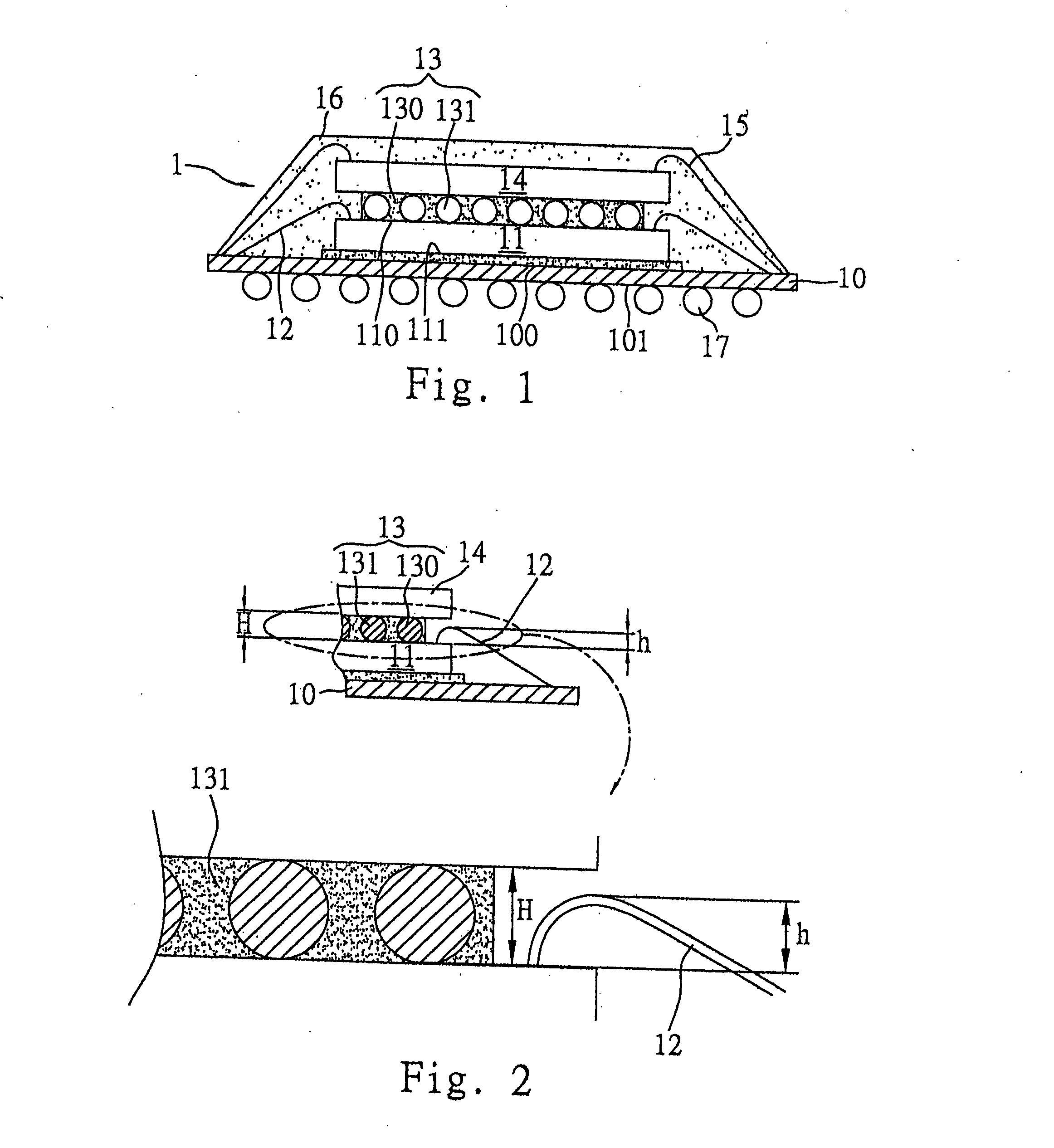

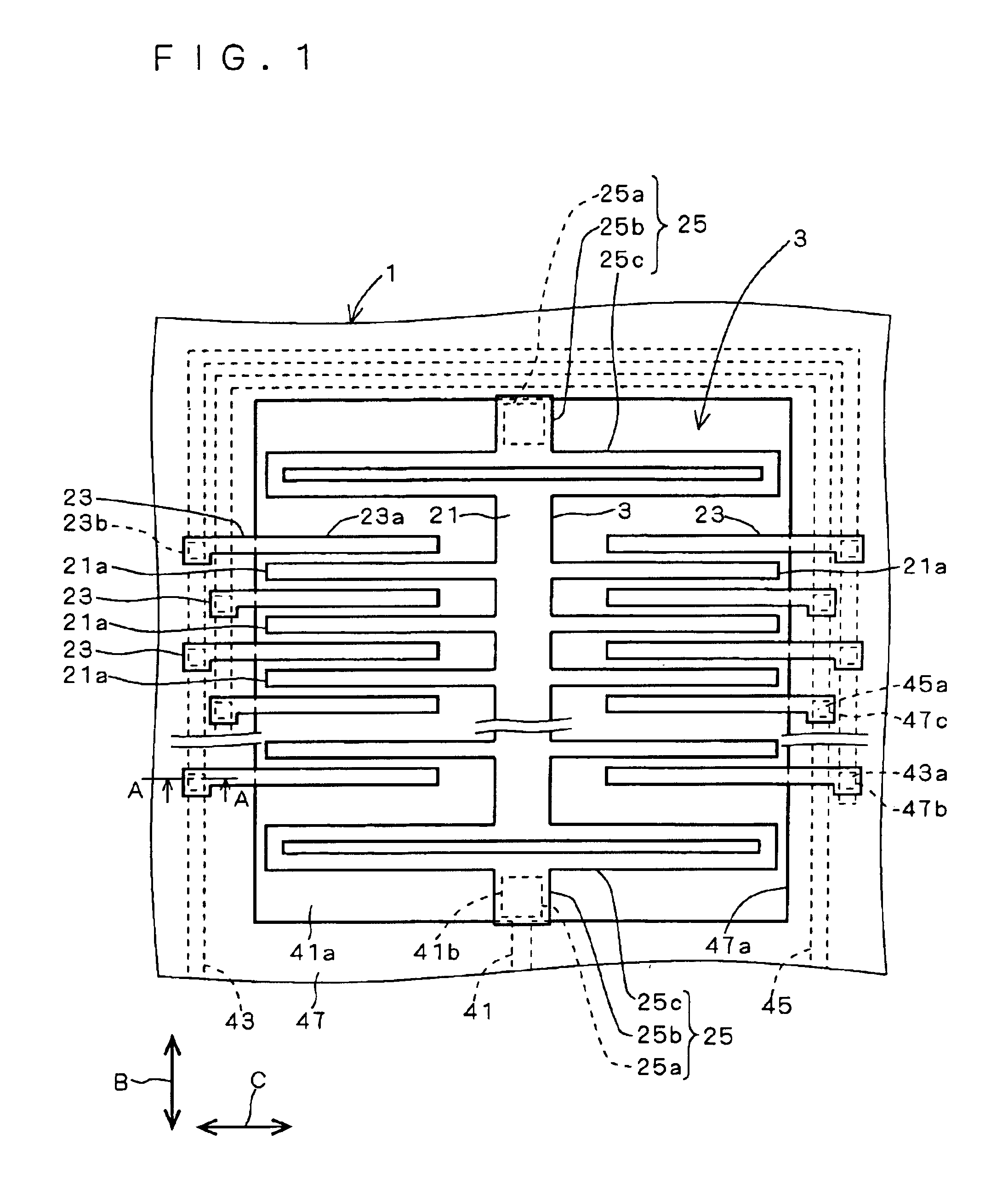

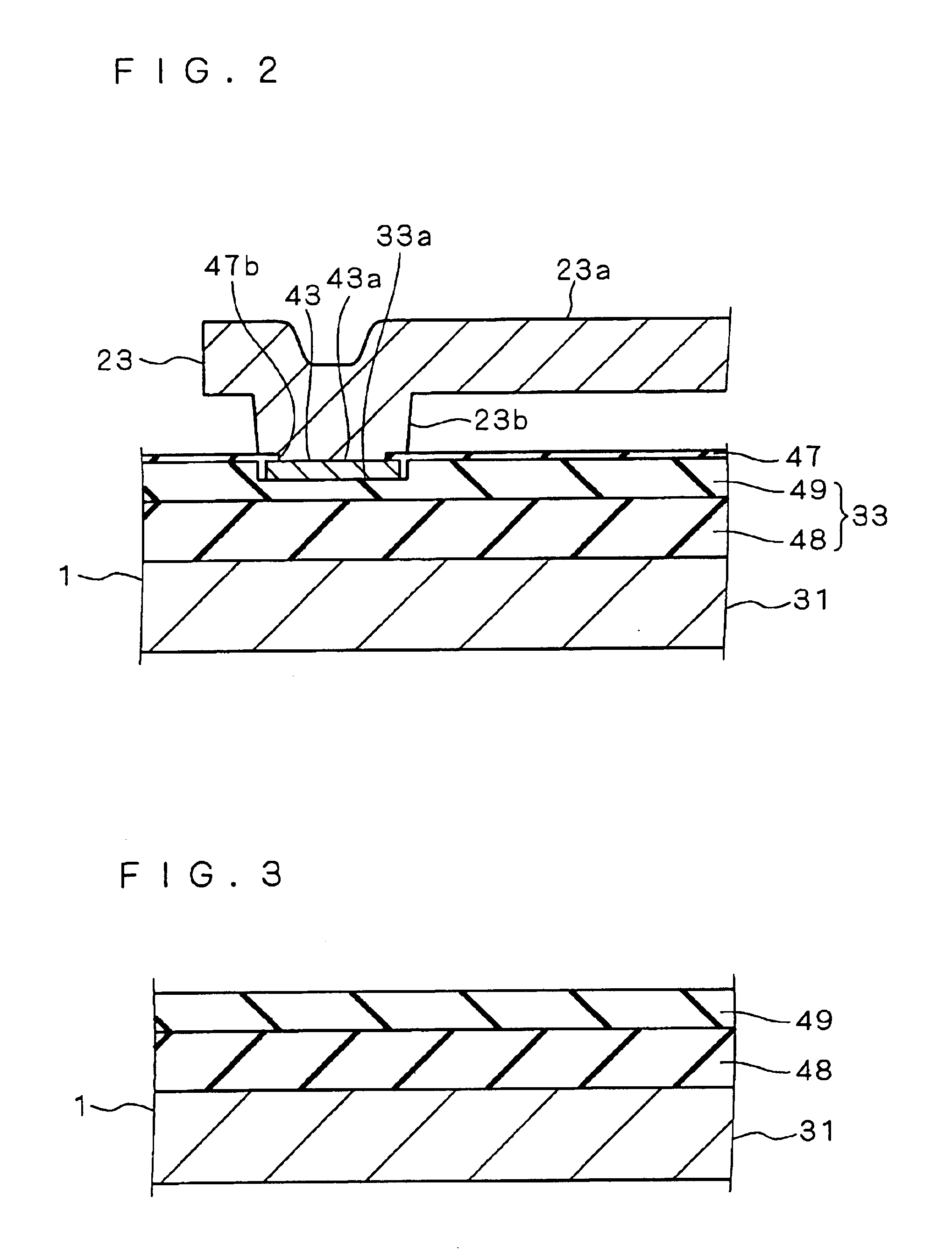

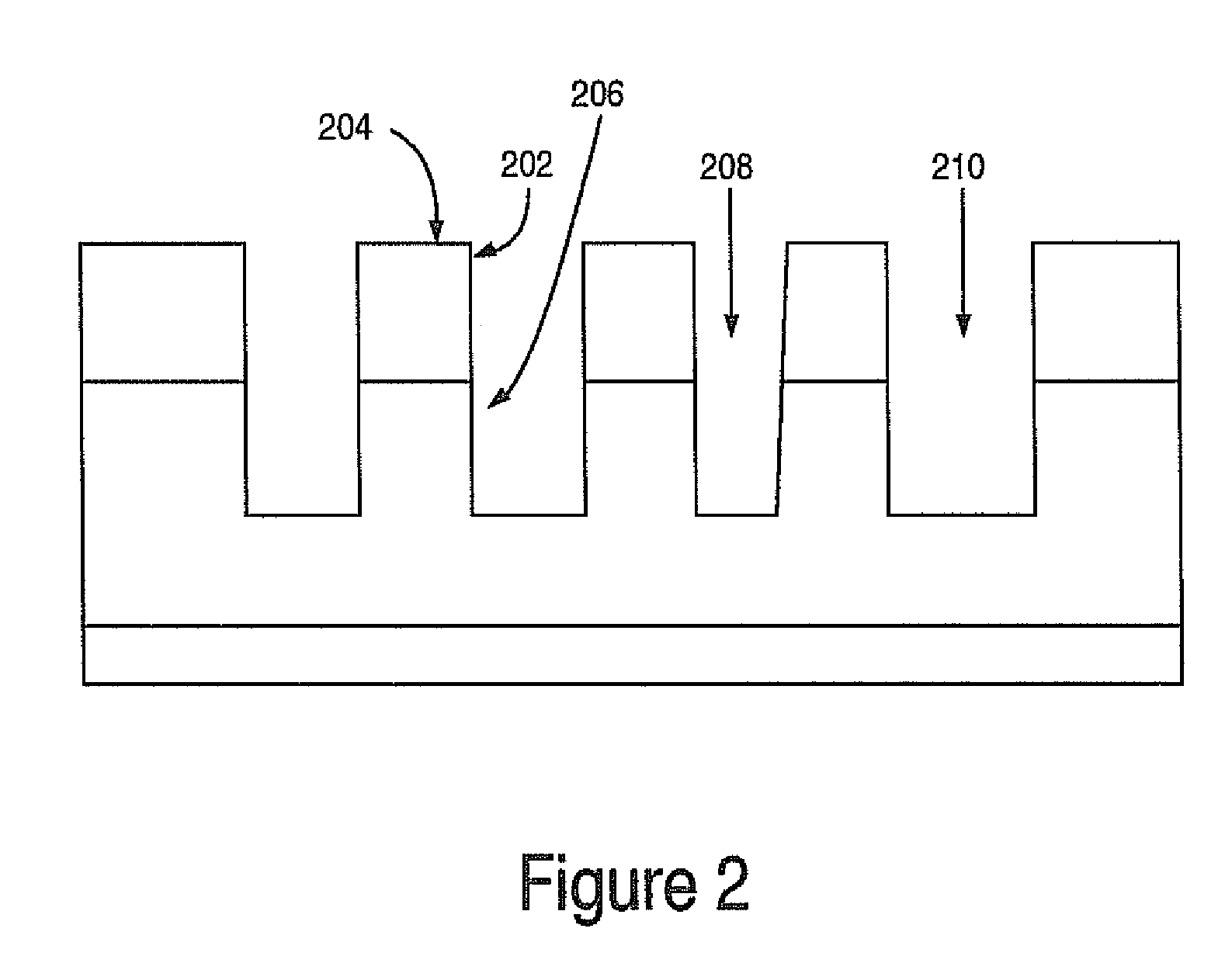

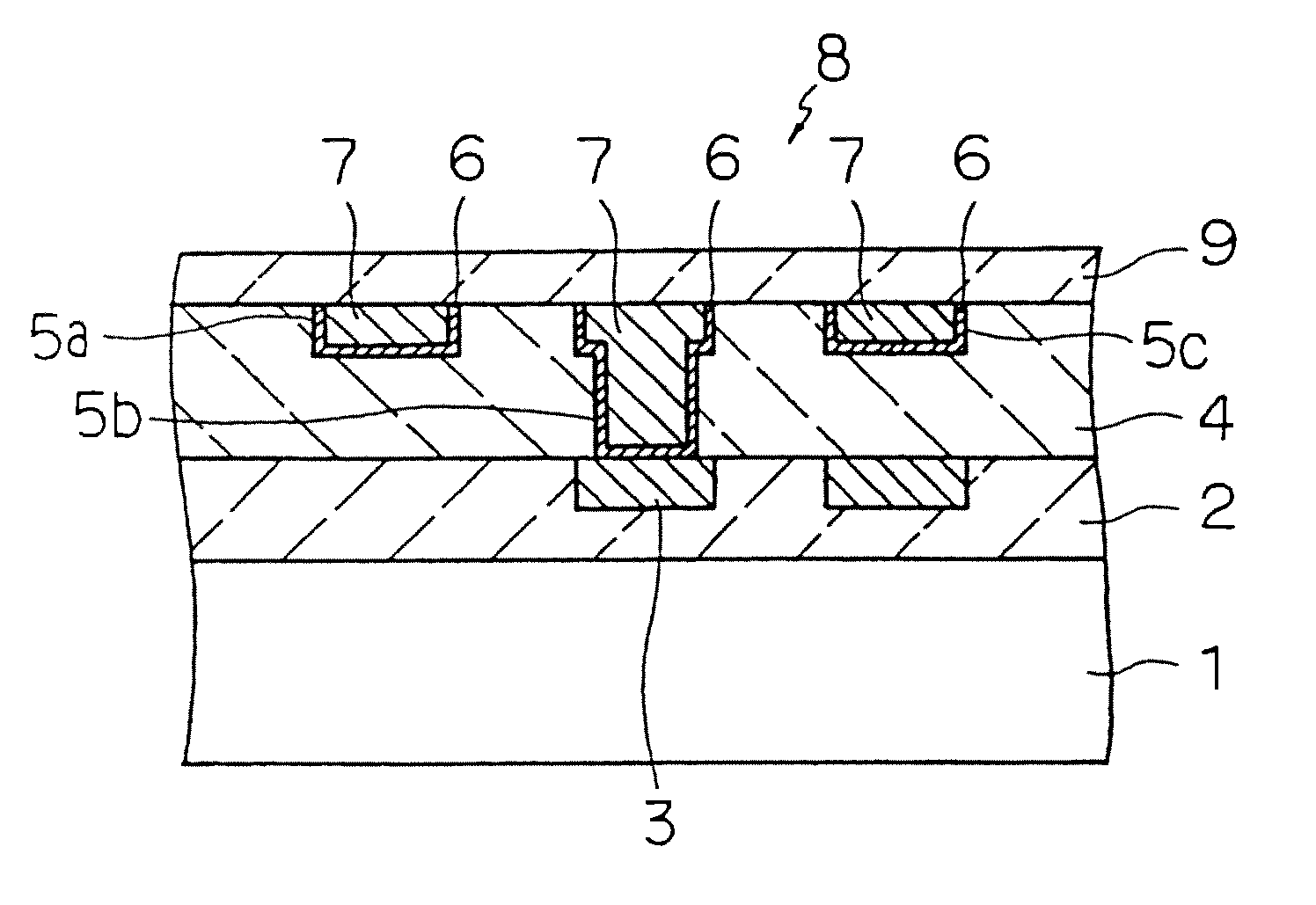

Multichip module

InactiveUS6919627B2Simplifies and reduces timeIncrease productionSemiconductor/solid-state device detailsSolid-state devicesAdhesiveSemiconductor chip

A multi-chip module is proposed, which is designed to pack two or more semi-conductor chips in a stacked manner over a chip carrier in a single package. The multi-chip module is characterized by the use of adhesive with fillers to allow the topmost chip (i.e. the second chip) superimposed to the bottommost chip (i.e. the first chip) after the first chip electrically connected to the chip carrier. The thickness of the adhesive layer depends on the diameter of the fillers higher than loop height of the bonding wires that is positioned above the active surface of the first chip to prevent the bonding wires connected to the first chip to come in contact with the overlaid chip.

Owner:SILICONWARE PRECISION IND CO LTD

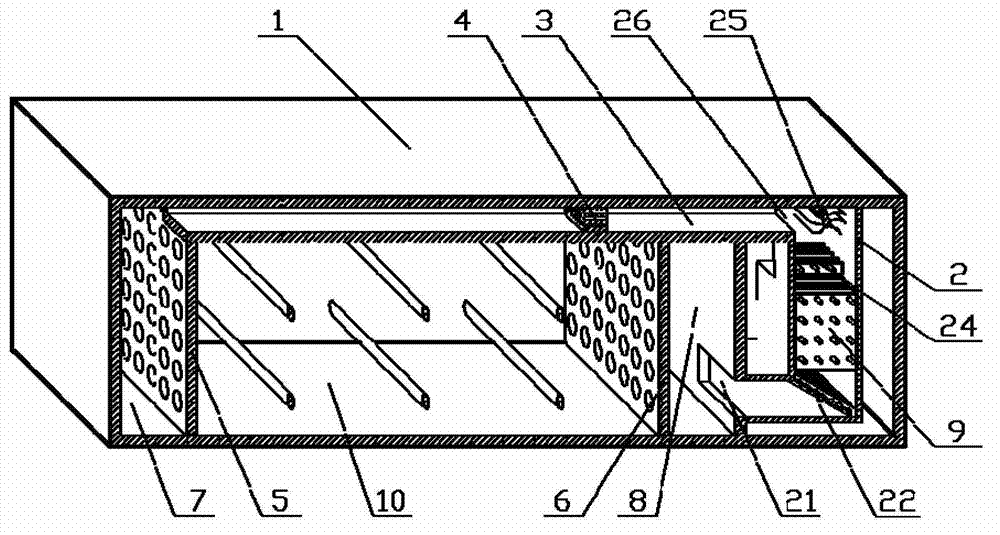

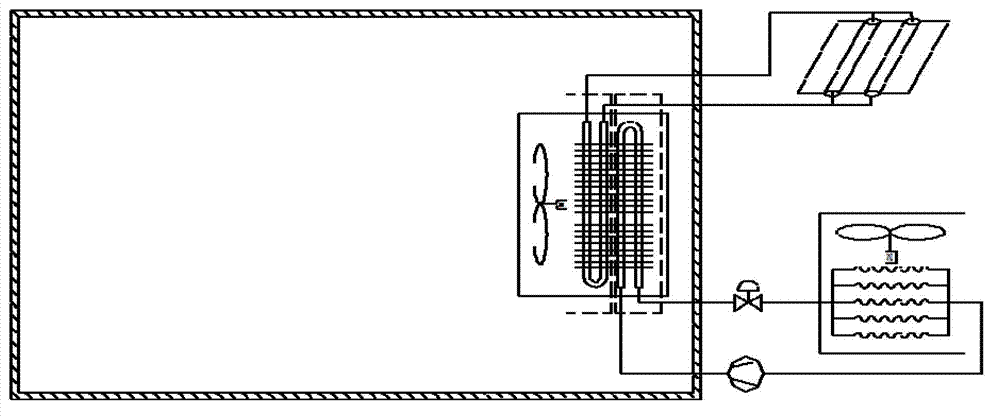

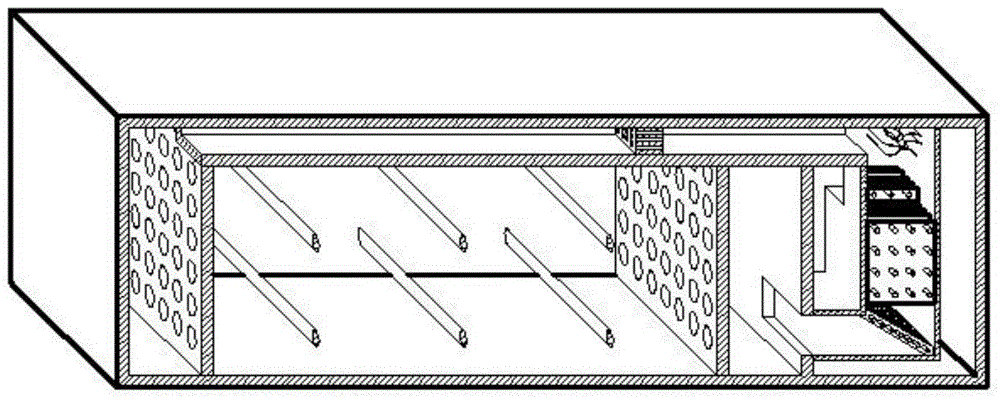

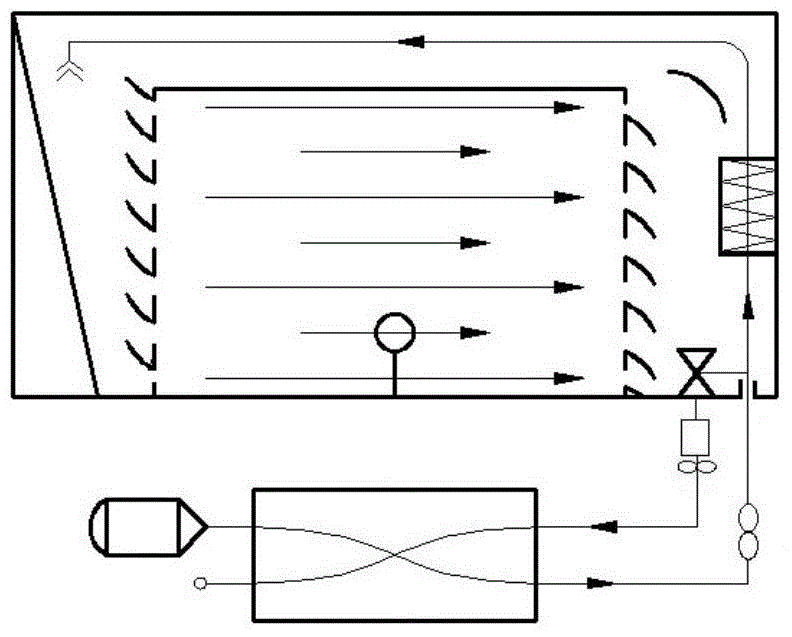

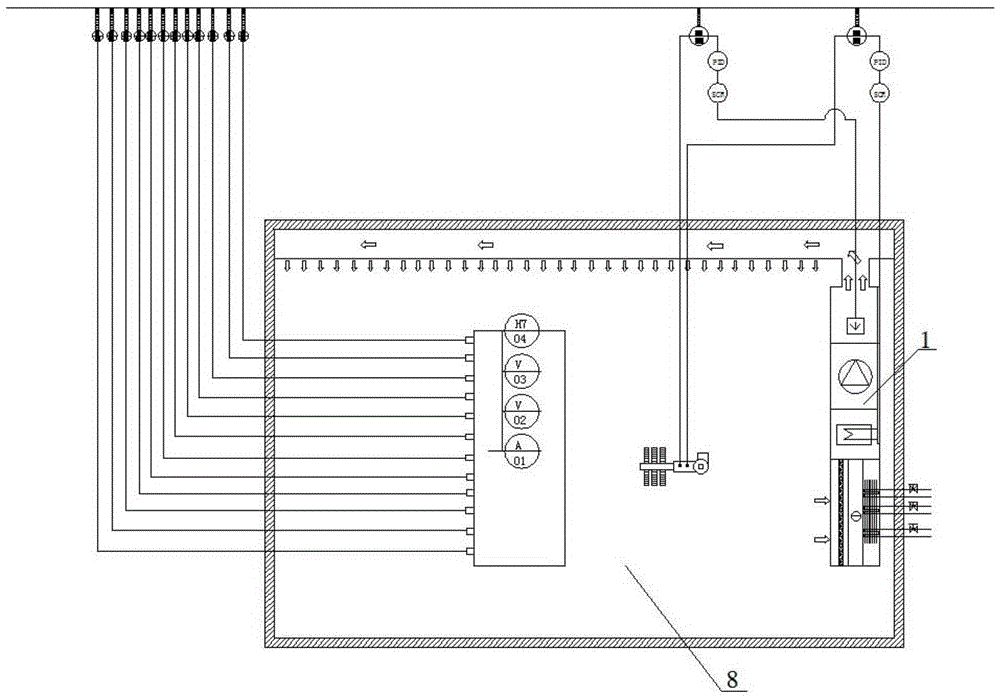

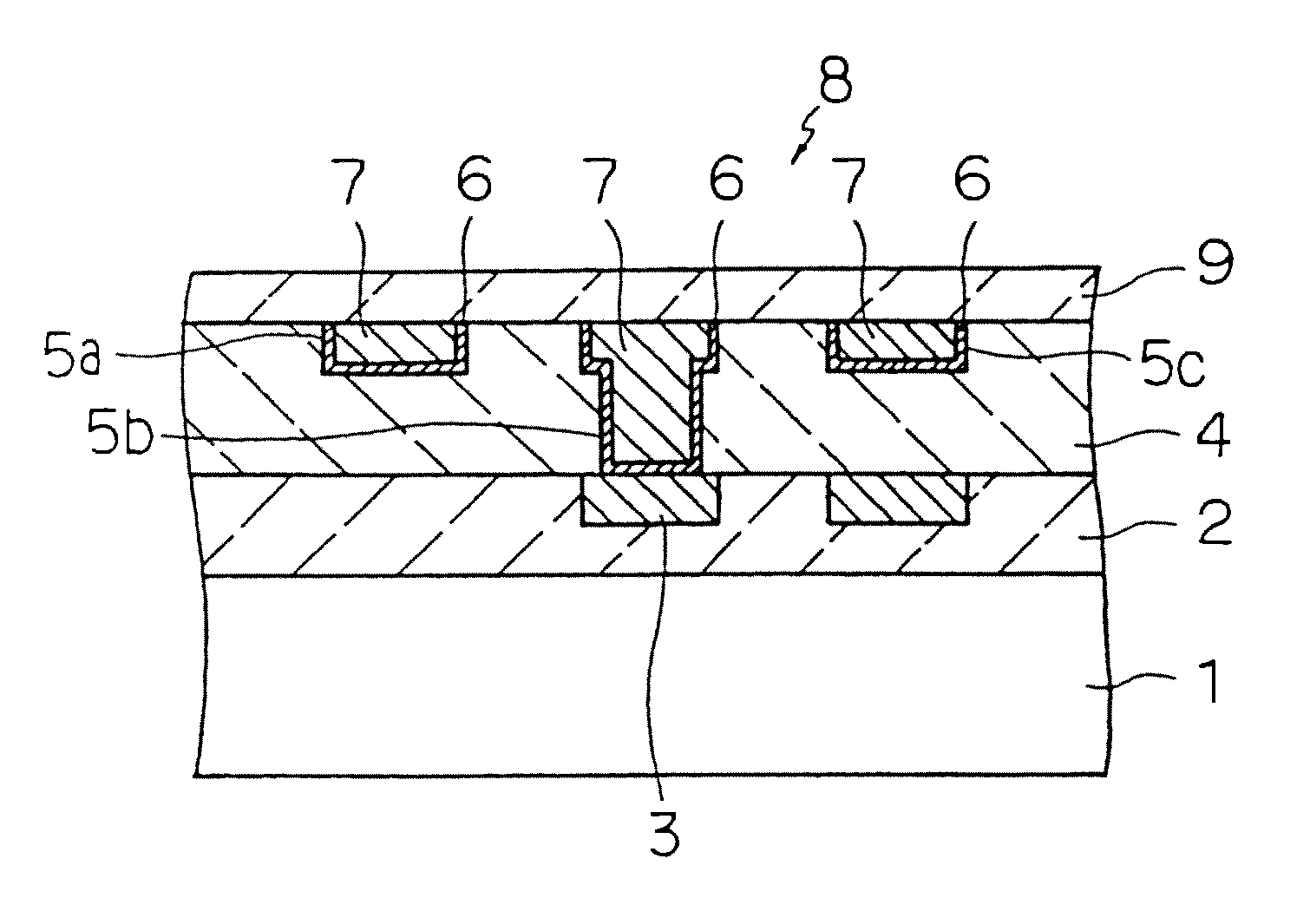

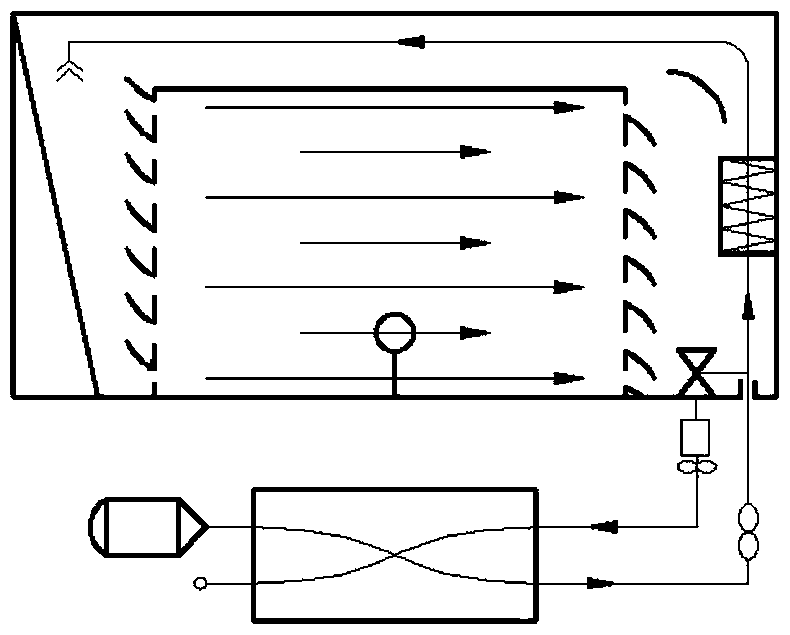

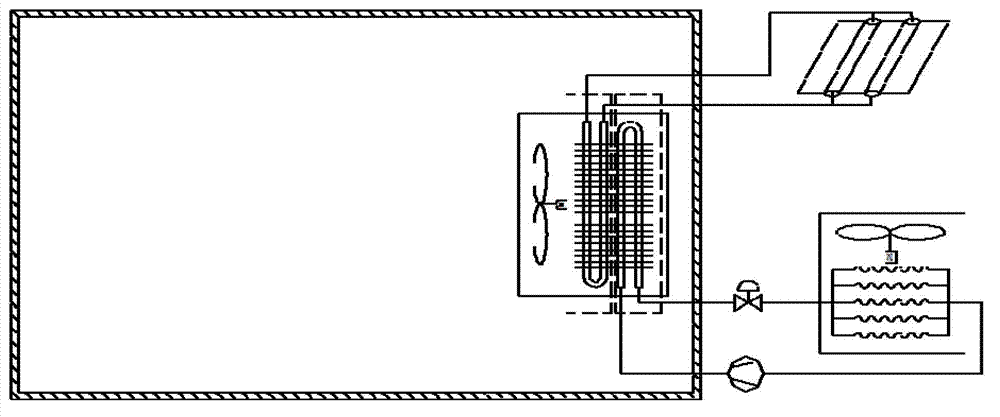

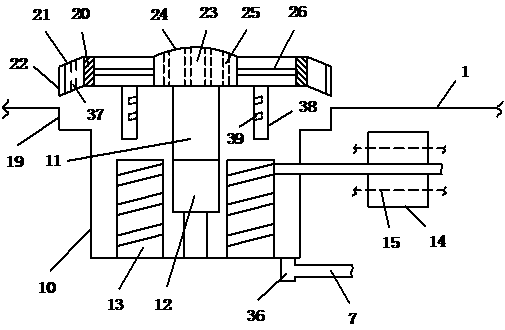

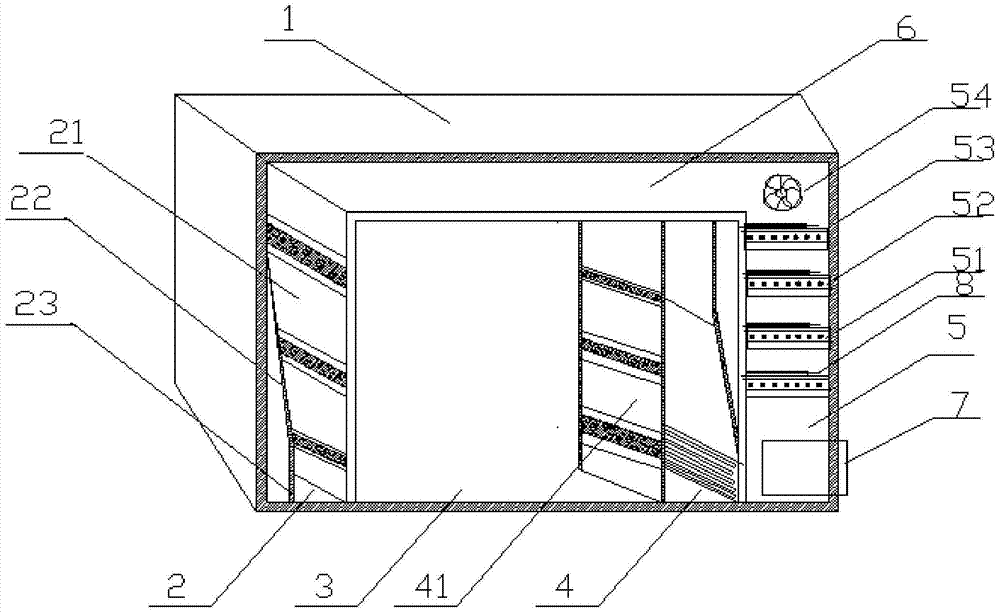

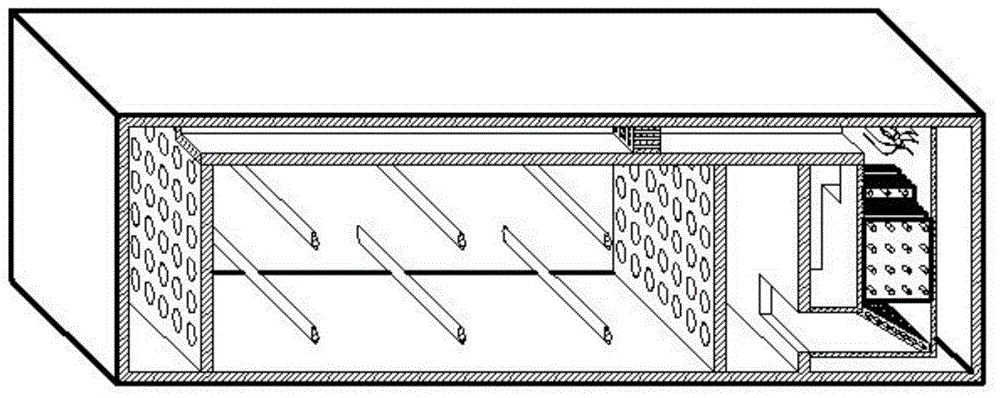

Edible fungus dried air circulation treatment device

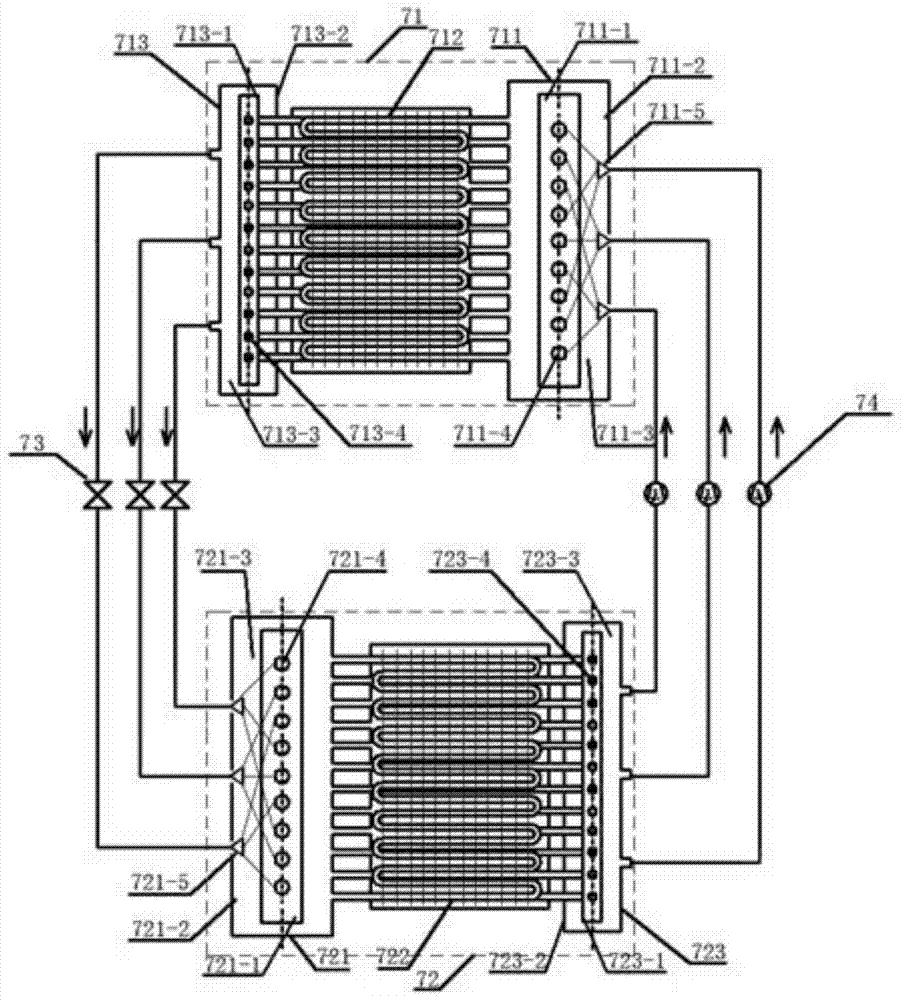

ActiveCN103202520ASuitable for dry conditionsWell organized airflowFood processingFood treatmentRefrigerant distributionThermodynamics

The invention discloses an edible fungus dried air circulation treatment device which comprises a baking chamber, an air treatment unit, an air supply header pipe, an air mixing device, and an air supply pore plate and an air return pore plate which are arranged in the baking chamber in parallel, wherein the baking chamber is segmented into an air supply static pressure space, an air return static pressure space and a baking workshop; the air treatment unit consists of an air inlet, a solid adsorption and dehumidification device, a heat pump loop, a fan, an auxiliary electric heater and an air outlet; the heat pump loop consists of a condenser and three groups of compressors and an evaporator assembly which are arranged in parallel; and the compressors and the evaporator assembly comprise an expansion valve, an evaporator and compressors which are sequentially connected. By employing the parallel air supply mode and the general-branch-general-branch refrigerant distribution mode, the air distribution is improved, and the uniformity and stability of the air flow and temperature field in the baking chamber during operation are guaranteed, so that the consistency of the baking effect is guaranteed, and the energy consumption in the process of operating the baking chamber at a low load is reduced.

Owner:NANJING NORMAL UNIVERSITY +1

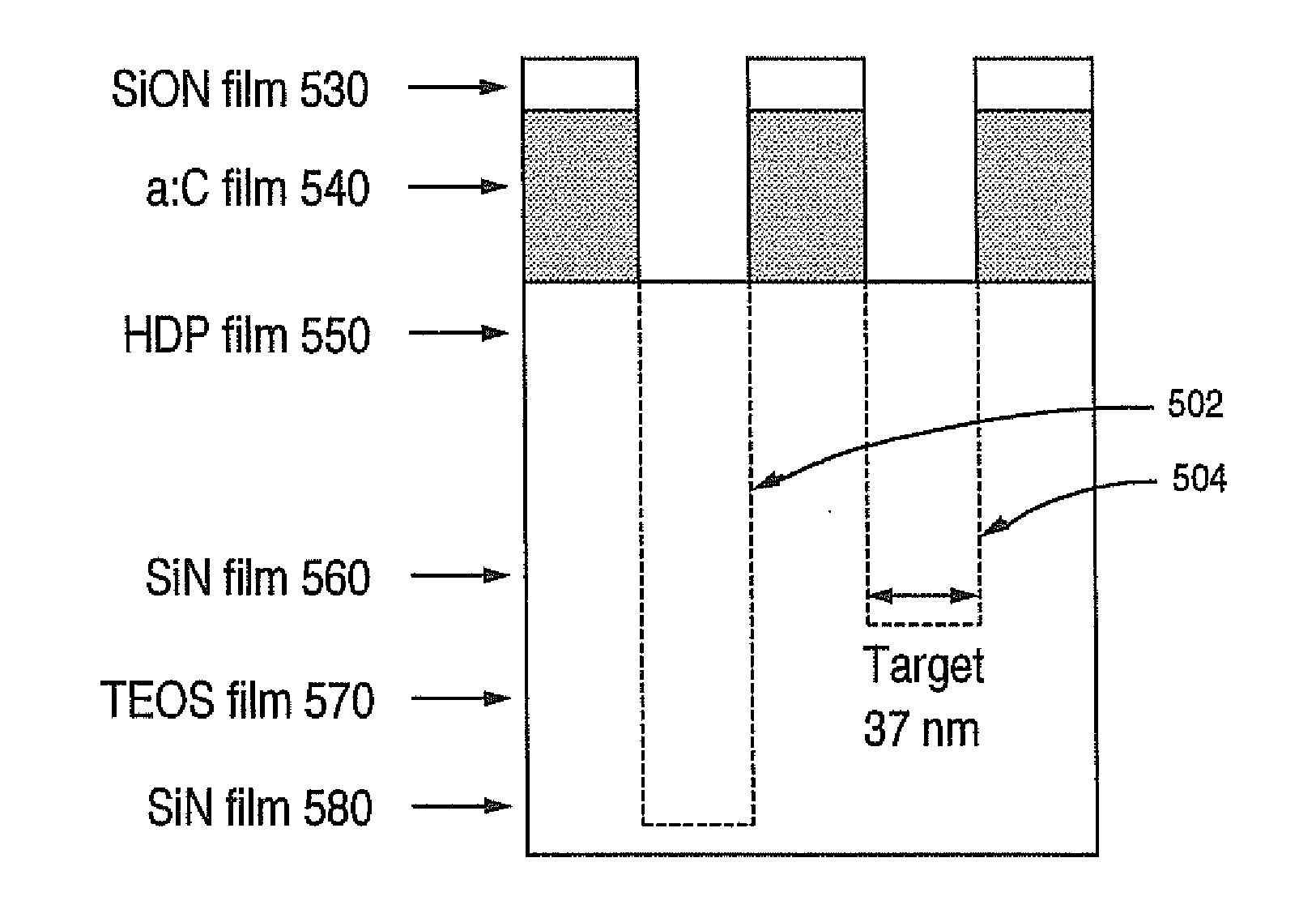

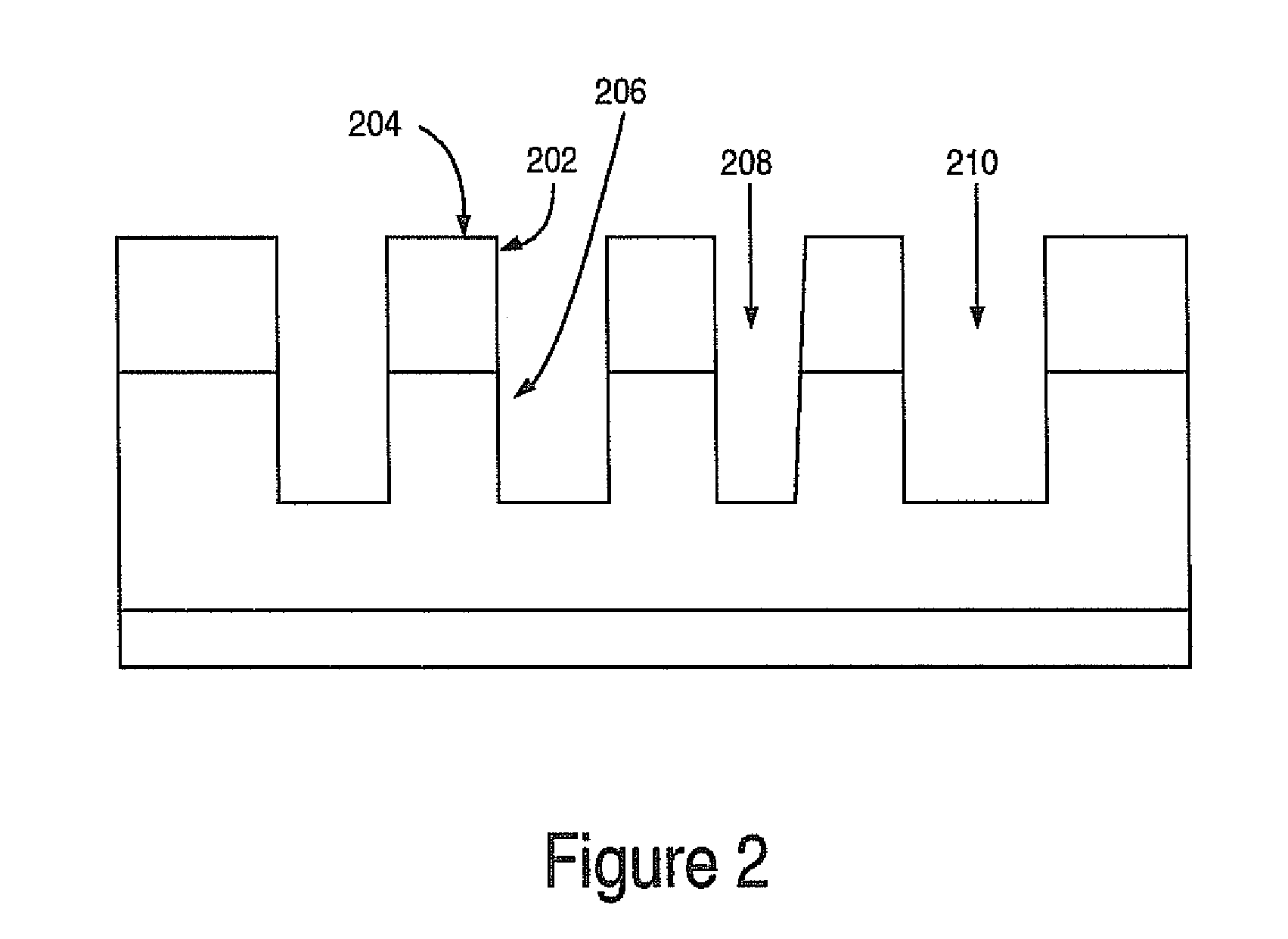

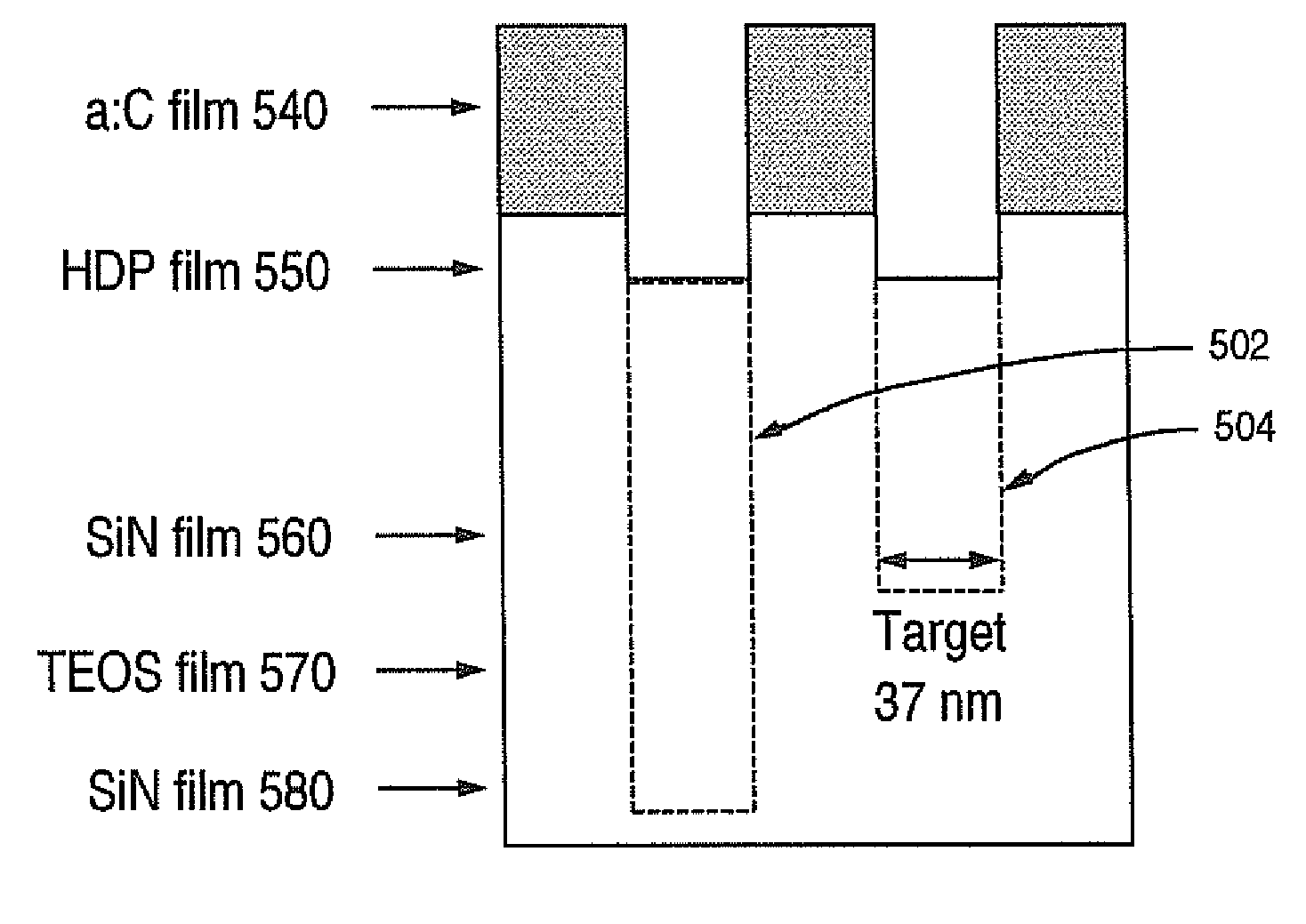

Line-edge roughness improvement for small pitches

ActiveUS20110159699A1Narrow downReducing film stress differenceSemiconductor/solid-state device manufacturingEtchingEngineering

A method for mitigating line-edge roughness on a semiconductor device. The method includes line-edge roughness mitigation techniques in accordance with embodiments of the present invention. The techniques include: reducing the SiON film thickness below a conventional thickness; increasing the photoresist thickness above a conventional thickness; etching the SiON film with an etch bias power less than a conventional wattage amount with an overetch percentage less than a conventional overetch percentage; removing the SiON film layer immediately after completion of the amorphous carbon film layer etching; and lowering the lower electrode temperature below a conventional temperature

Owner:SPANSION LLC

Manufacturing method for multichip module

InactiveUS20050006785A1Reduce coefficientFluidity be reduceSemiconductor/solid-state device detailsSolid-state devicesThermal conductivityAluminium

A manufacturing method for a multi-chip module is provided, which is designed to pack two or more semi-conductor chips in a stacked manner over a chip carrier in a single package. An adhesive with fillers allows a second chip to be superimposed over a first chip after the first chip is electrically connected to the chip carrier. The diameter of the fillers is higher than loop height of the bonding wires that are positioned above the active surface of the first chip to prevent the bonding wires to come in contact with the second chip. Moreover, the other embodiment of the fillers (such as copper or aluminum) with high thermal conductivity is also capable of enhancing heat dissipation of the stacked package application.

Owner:SILICONWARE PRECISION IND CO LTD

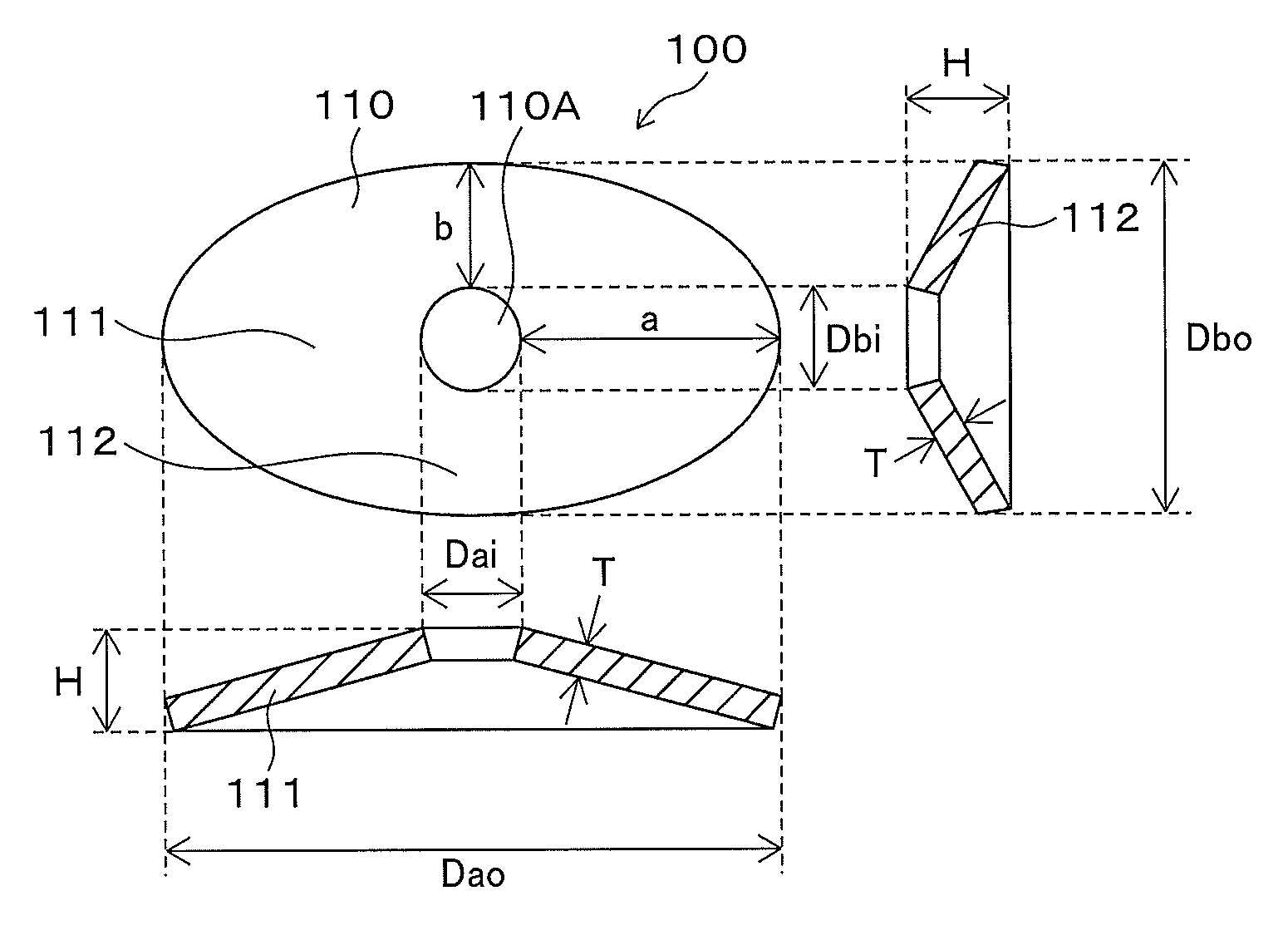

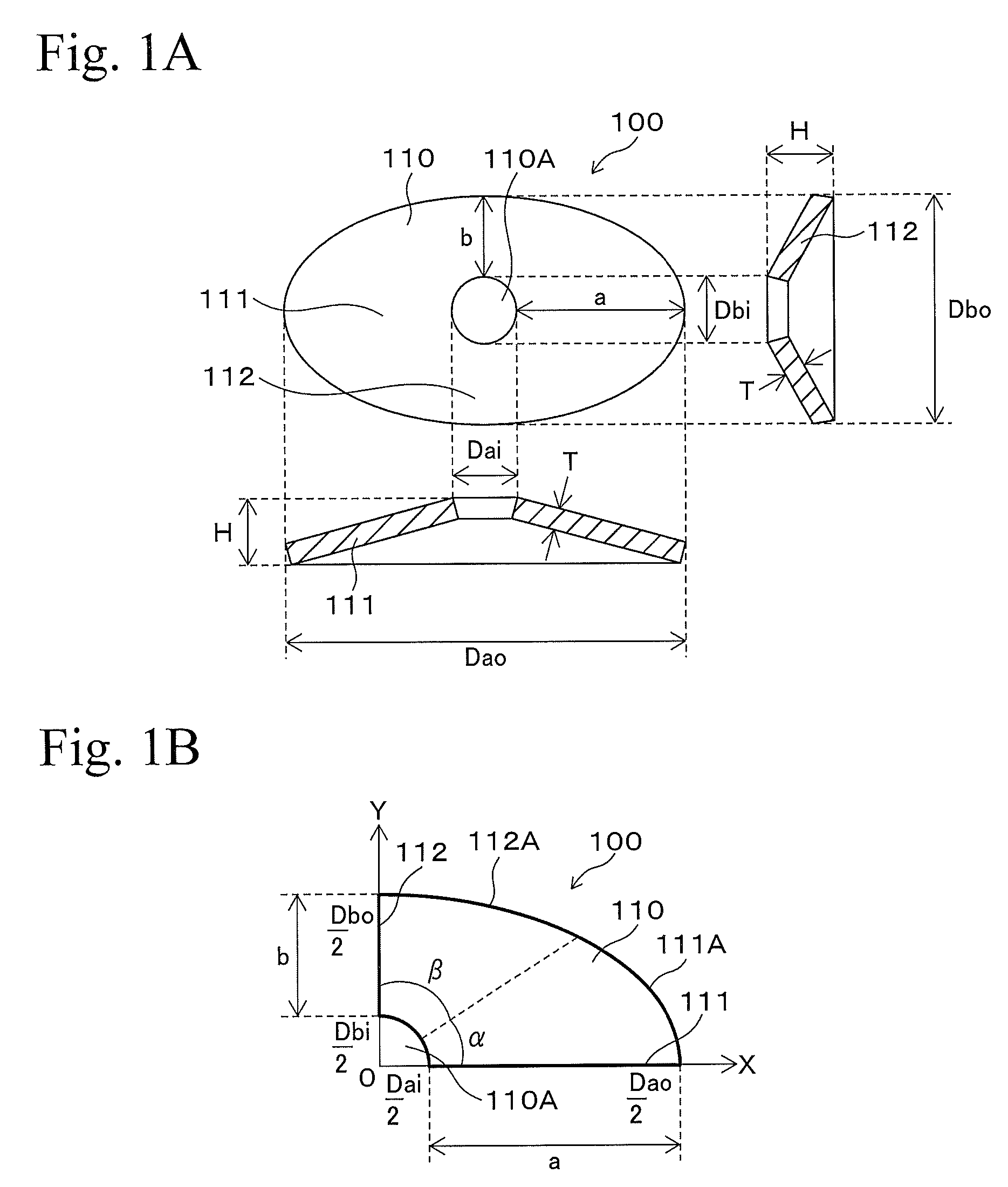

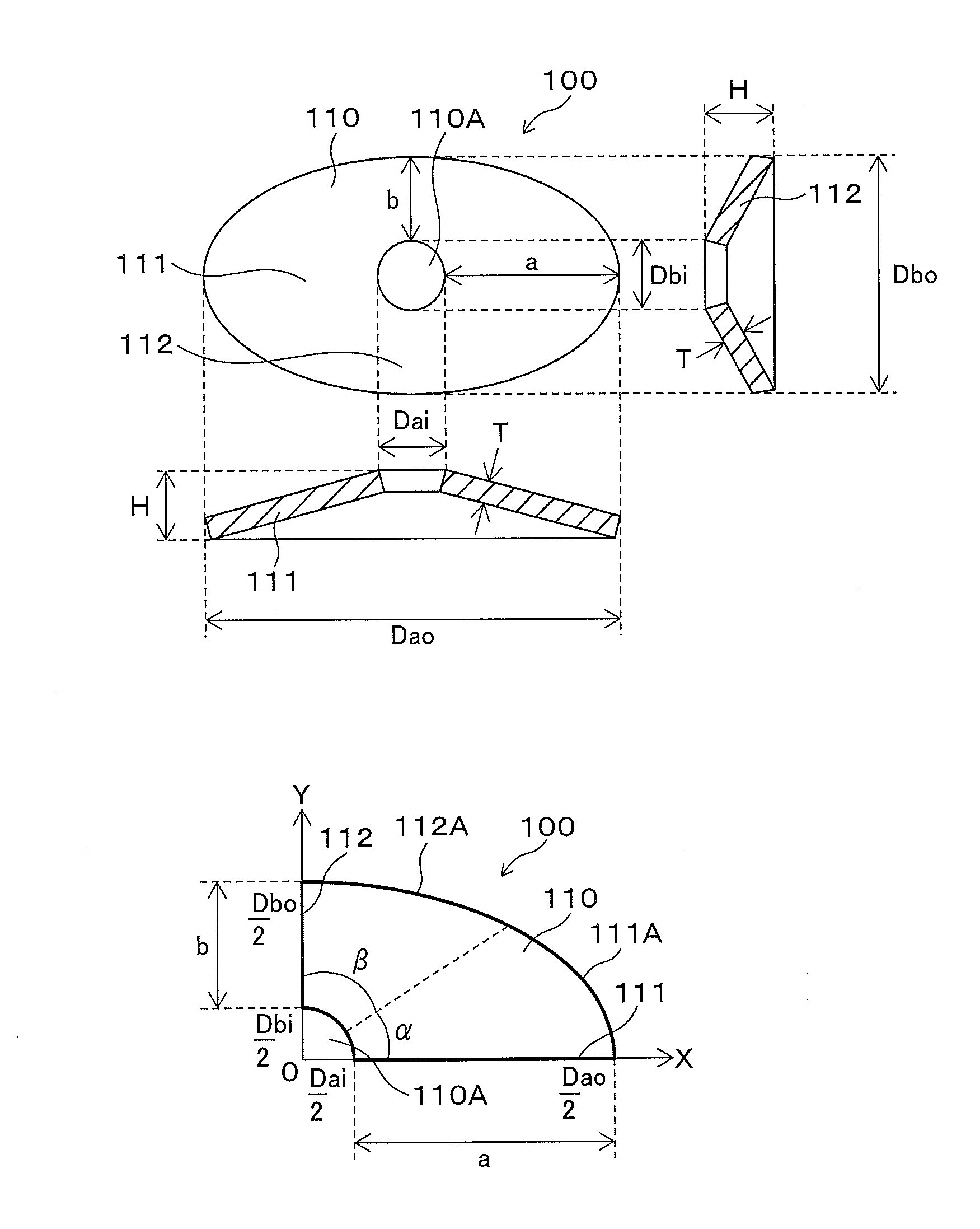

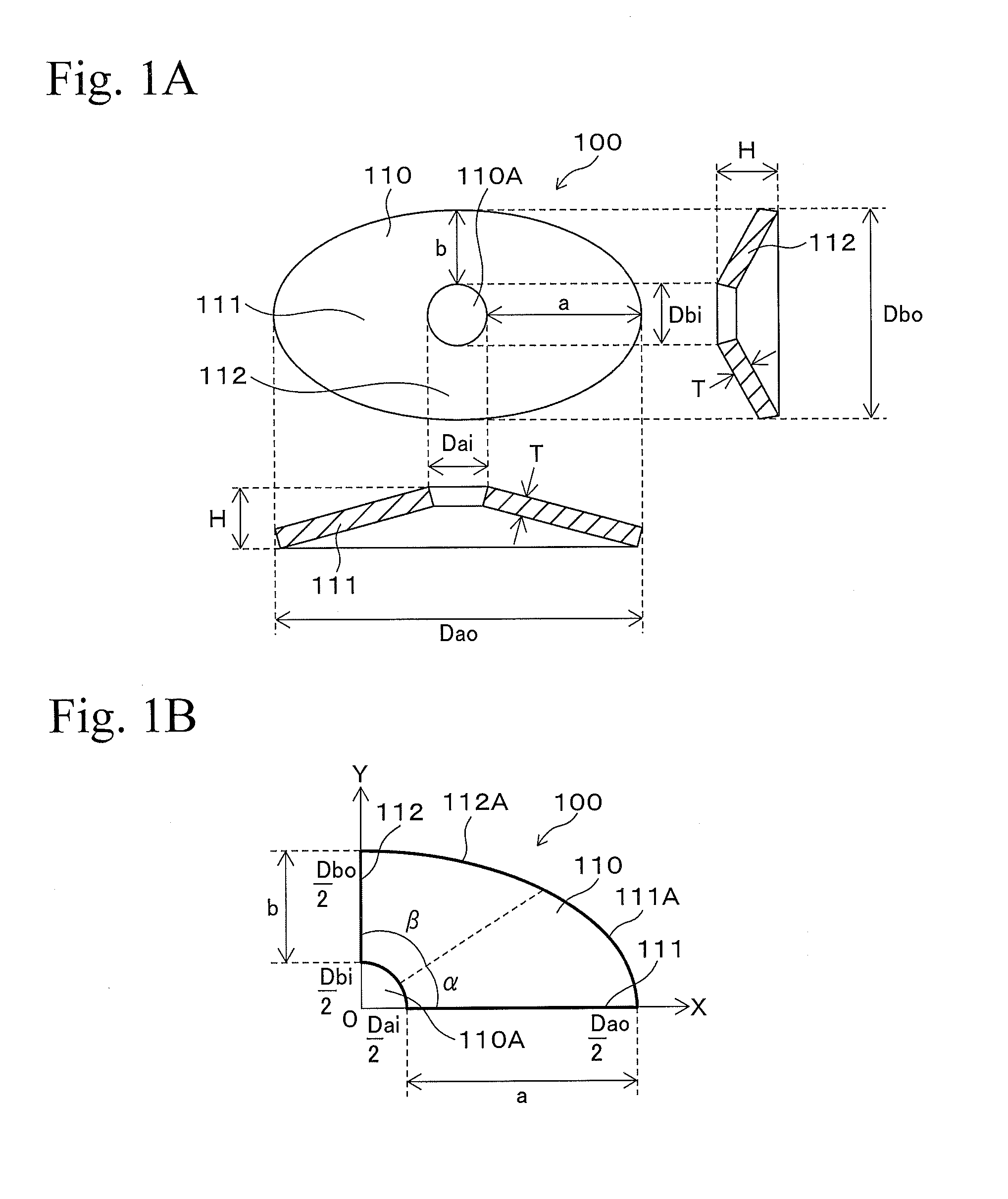

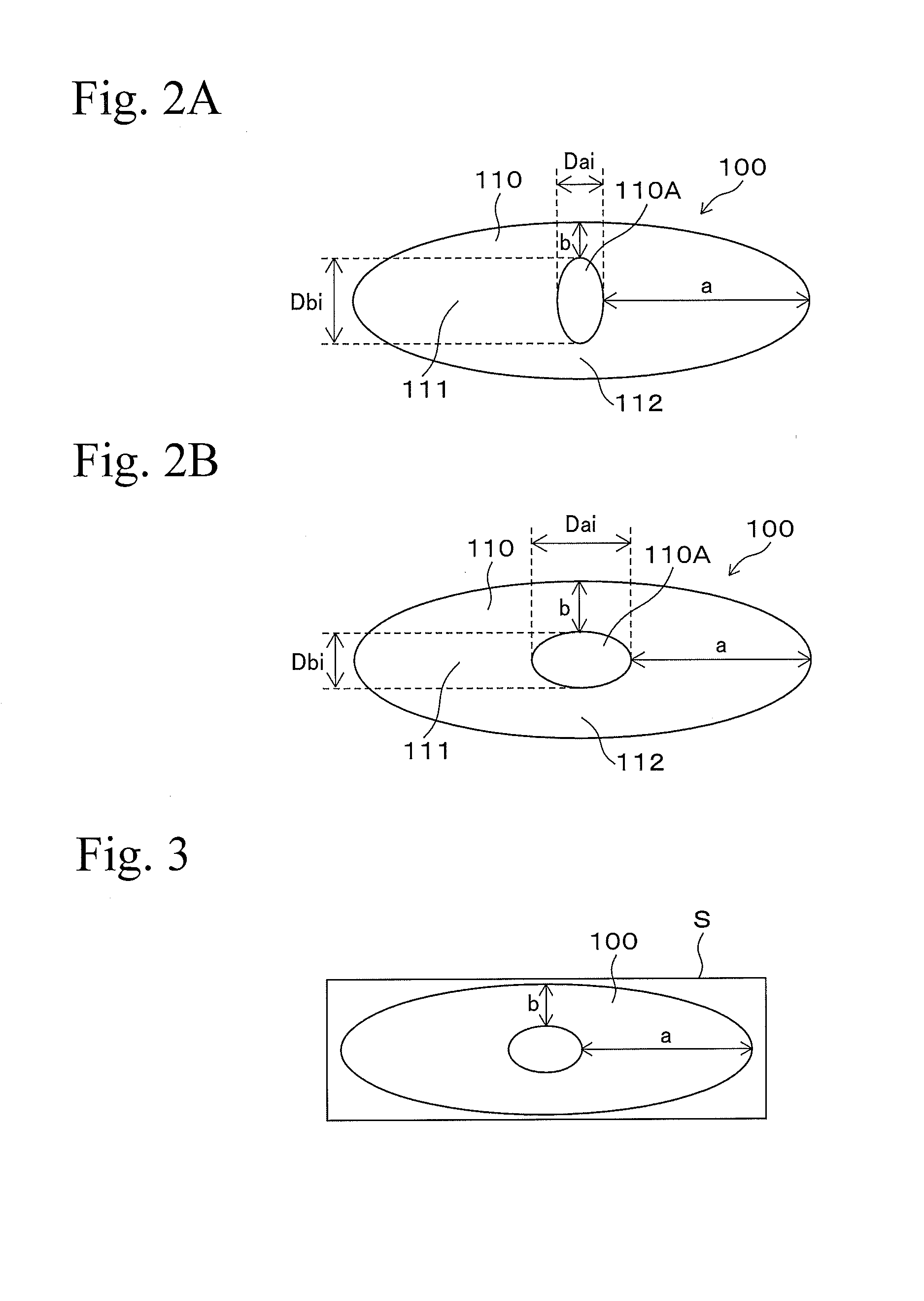

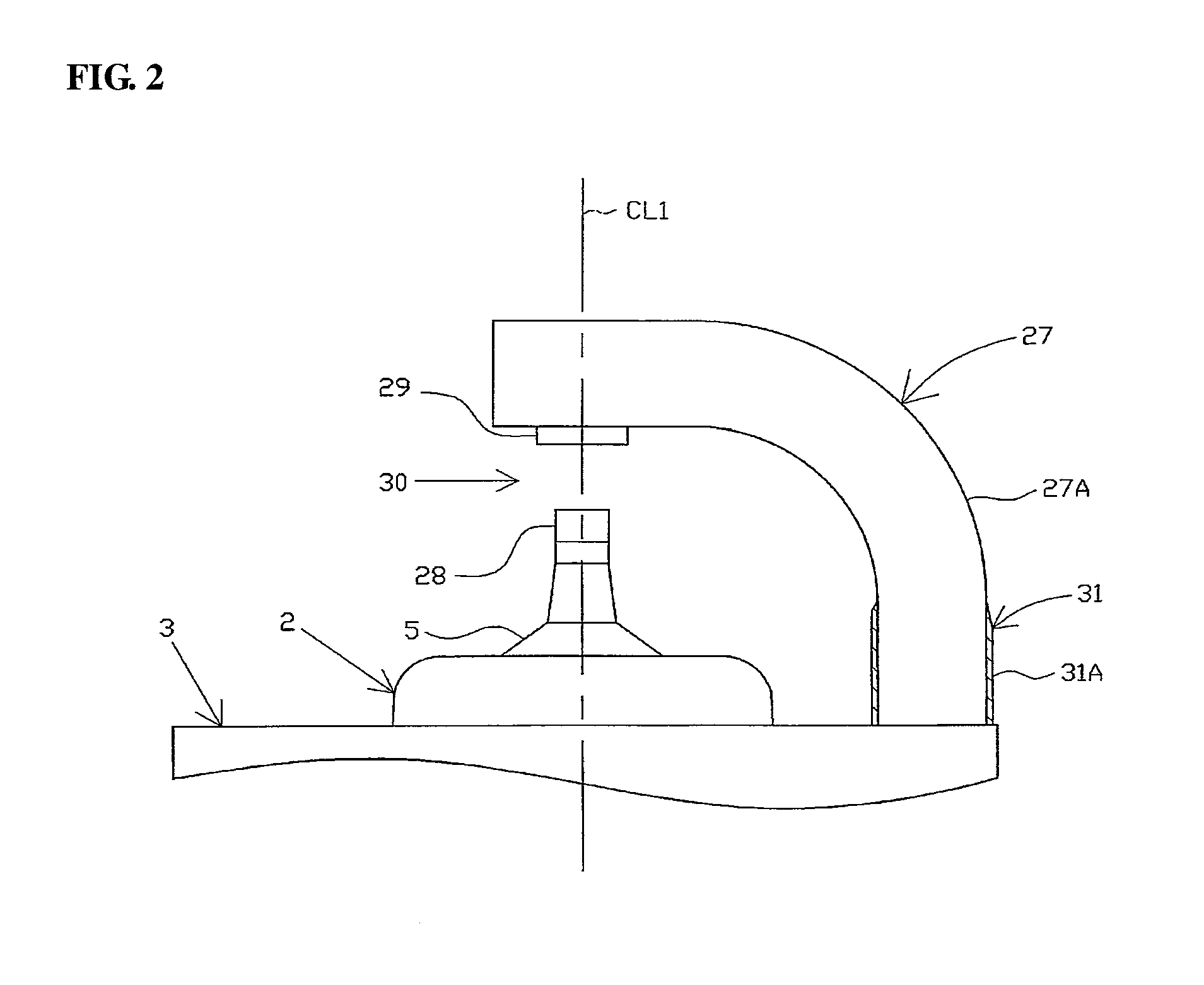

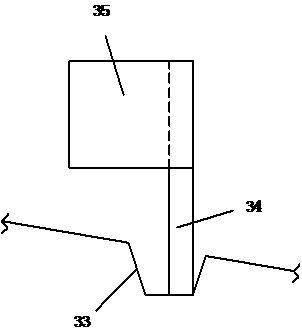

Coned disc spring

ActiveUS9400027B2Reduce stress differentialNon-linear load characteristicsBelleville-type springsRing springsEllipseEngineering

An elliptical coned disc spring can be accommodated in a rectangular installation space, can yield non-linear load characteristics, and can reduce stress differences between a bending part at a long radial part side and a bending part at a short radial part side. An elliptical coned disc spring has a body in which an outer circumference is an ellipse in a disc shape. A hole is formed at the center of the body. The hole may have various shapes such as a circle, an ellipse, etc. The body has a long radial part 111 and a short radial part. A plate width of the long radial part is set to be greater than a plate width of the short radial part (that is, a>b).

Owner:NHK SPRING CO LTD

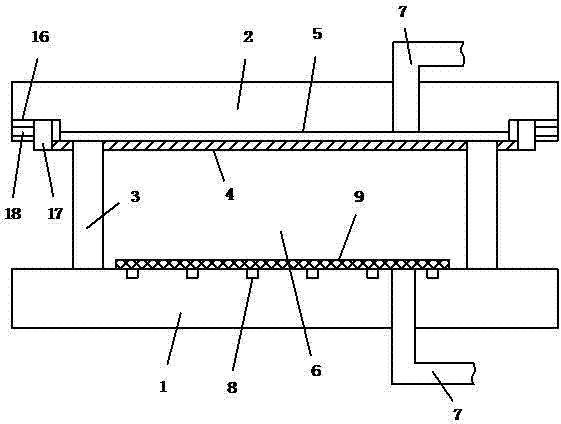

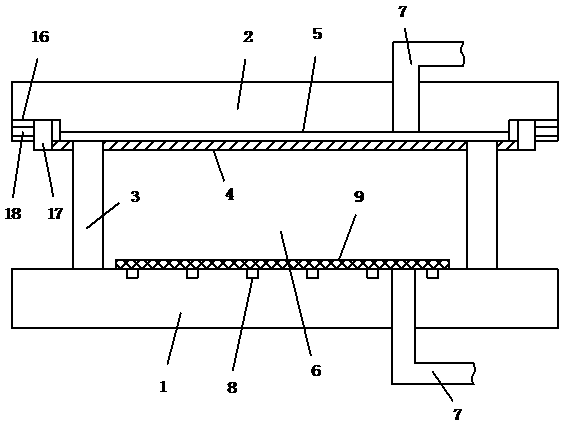

Laminating apparatus for solar assembly and laminating packaging method thereof

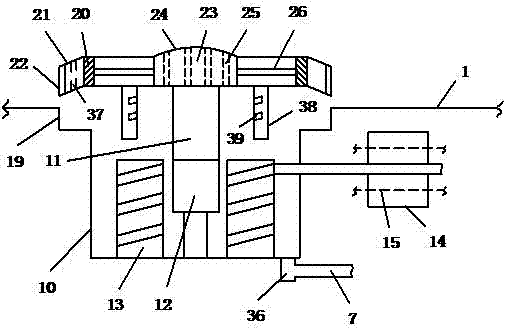

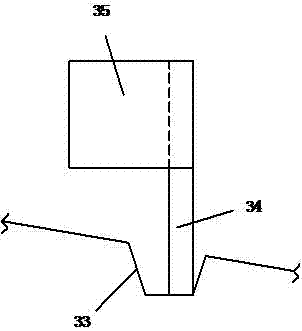

InactiveCN106972073AImprove the temperature field distributionImprove the uniformity of temperature field distributionFinal product manufactureLaminationHydraulic cylinderSilica gel

The present invention discloses a laminating apparatus for a solar assembly. The laminating apparatus comprises a substrate and a pressing plate; a hydraulic cylinder drives the pressing plate to move up and down, so that the substrate and the pressing plate can be pressed together; the bottom surface of the pressing plate is provided with a silica gel film; the surface of the substrate is provided with a plurality of pushing pins; a cushion is laid on the pushing pins; mounting holes are arranged formed in the substrate; the pushing pins are installed in the mounting holes through lifting rods; the bottoms of the lifting rods are provided with heat insulating sleeves; electric heating wires are arranged in the substrate; the bottoms of the mounting holes are provided with spiral oil guiding tubes; annular grooves are formed at the tops of the mounting holes; the edges of the pushing pins are provided with metal elastic sheets through first springs; the external sides of the metal elastic sheets are provided with silica gel dumping cushions; the edge of the pressing plate is provided with slide rails; a clamping block is slidingly arranged in each slide rail; each clamping block is connected with a corresponding first air cylinder; and the clamping blocks are fixedly held at the edge of the silica gel film. With the laminating apparatus of the invention adopted, defects in the prior art can be eliminated, and the heating and pressure uniformity of components in a laminating process can be improved, and the yield of products can be improved.

Owner:江苏盐芯微电子有限公司

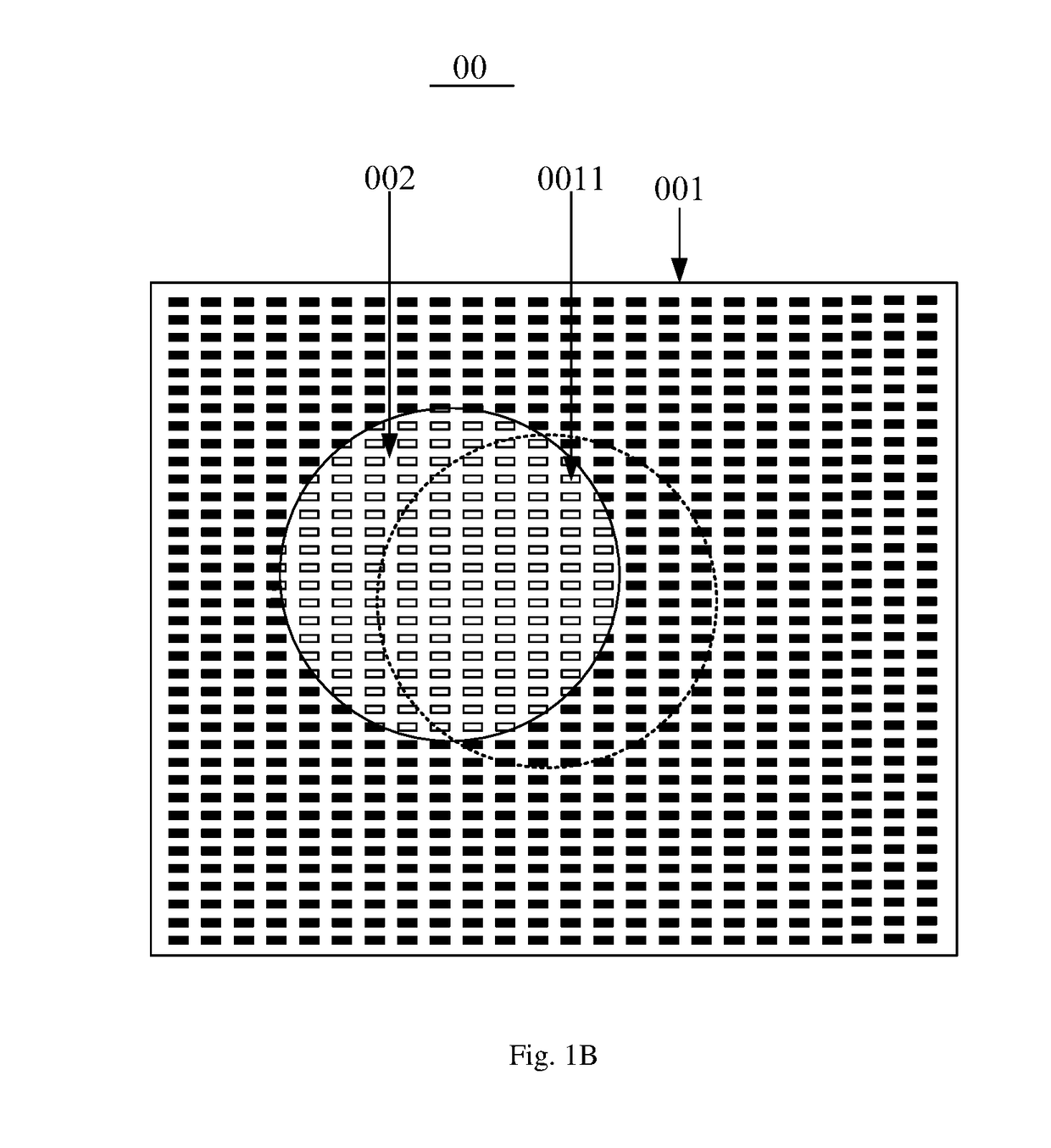

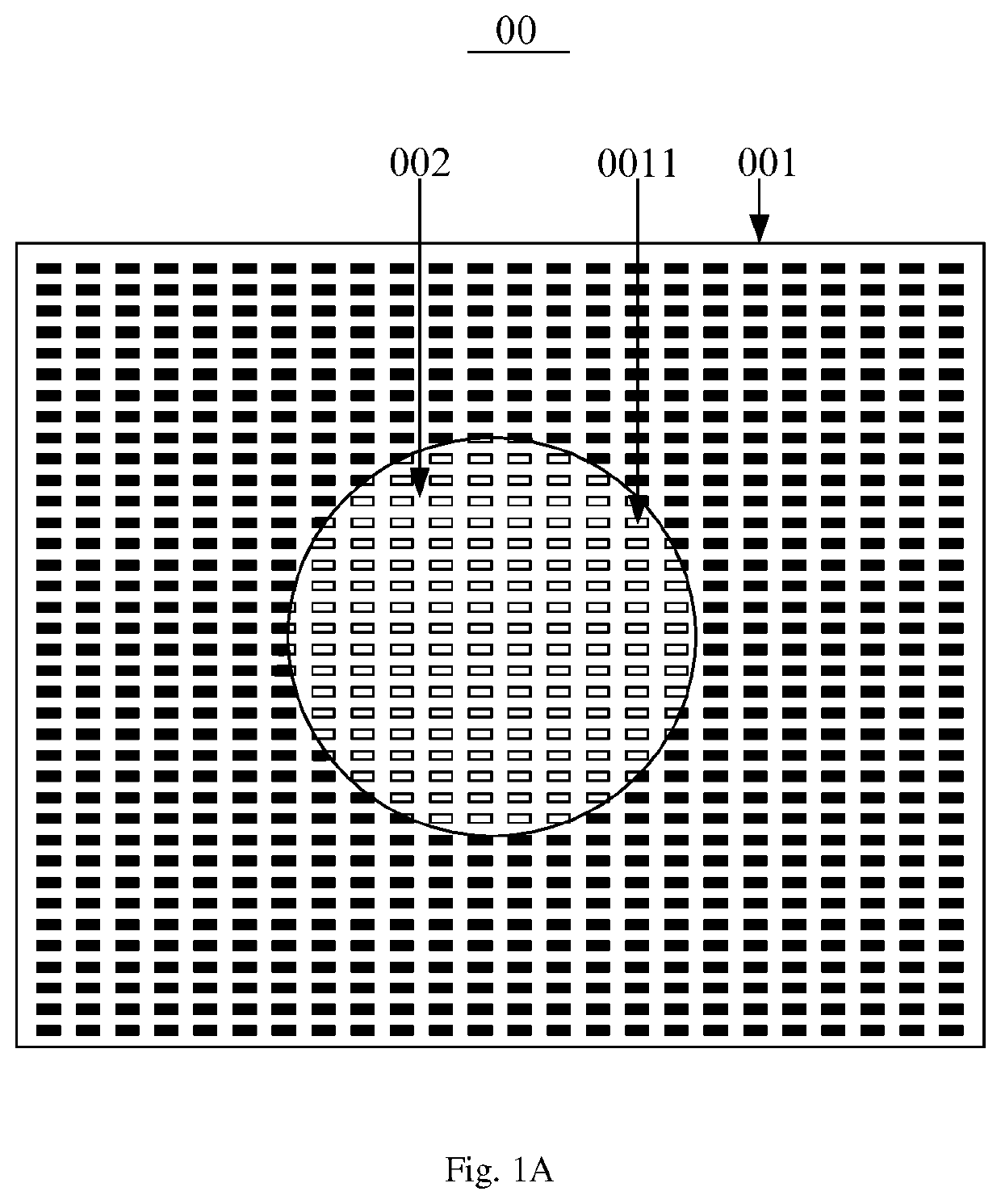

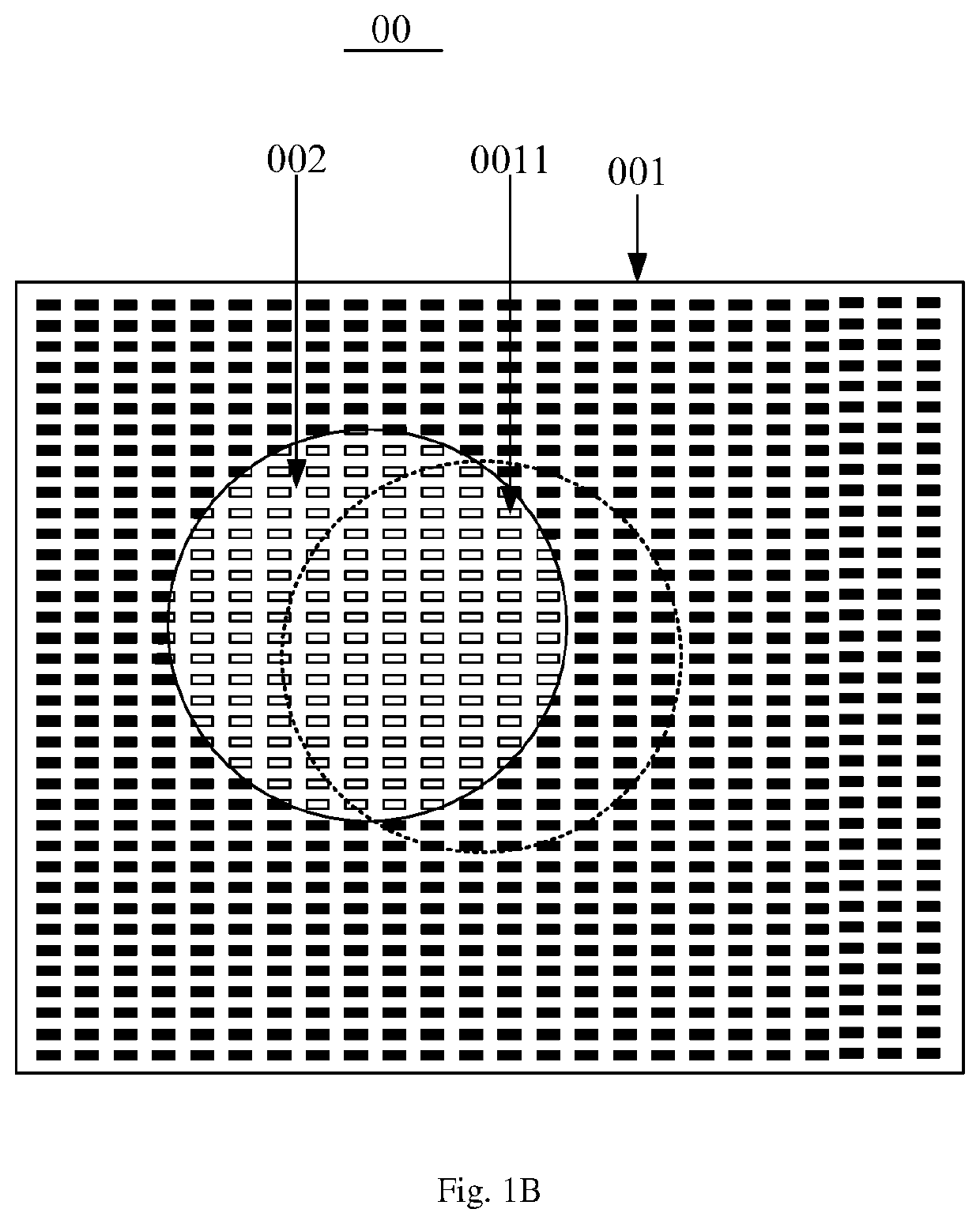

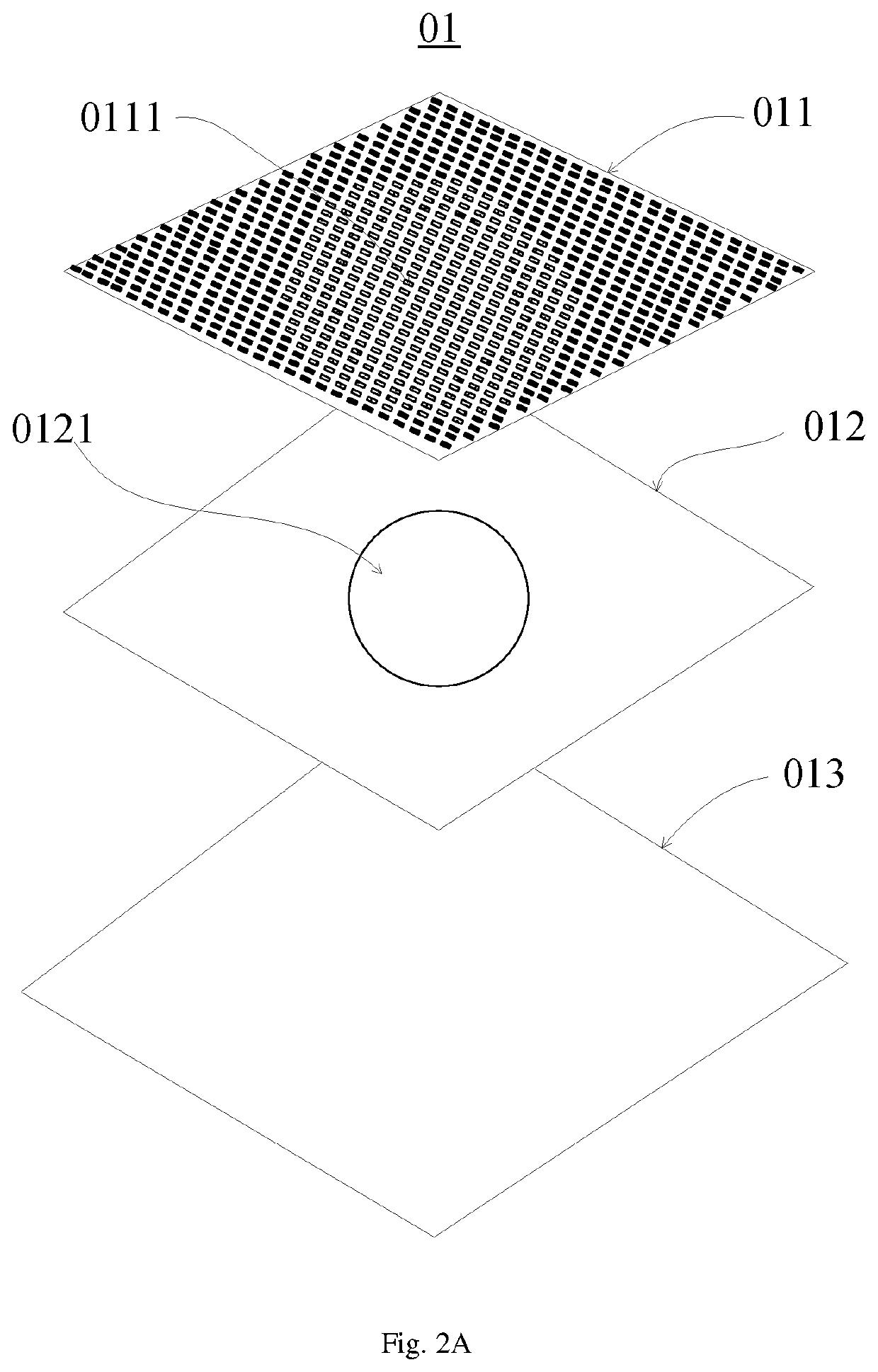

Mask assembly and method for manufacturing the same and display device

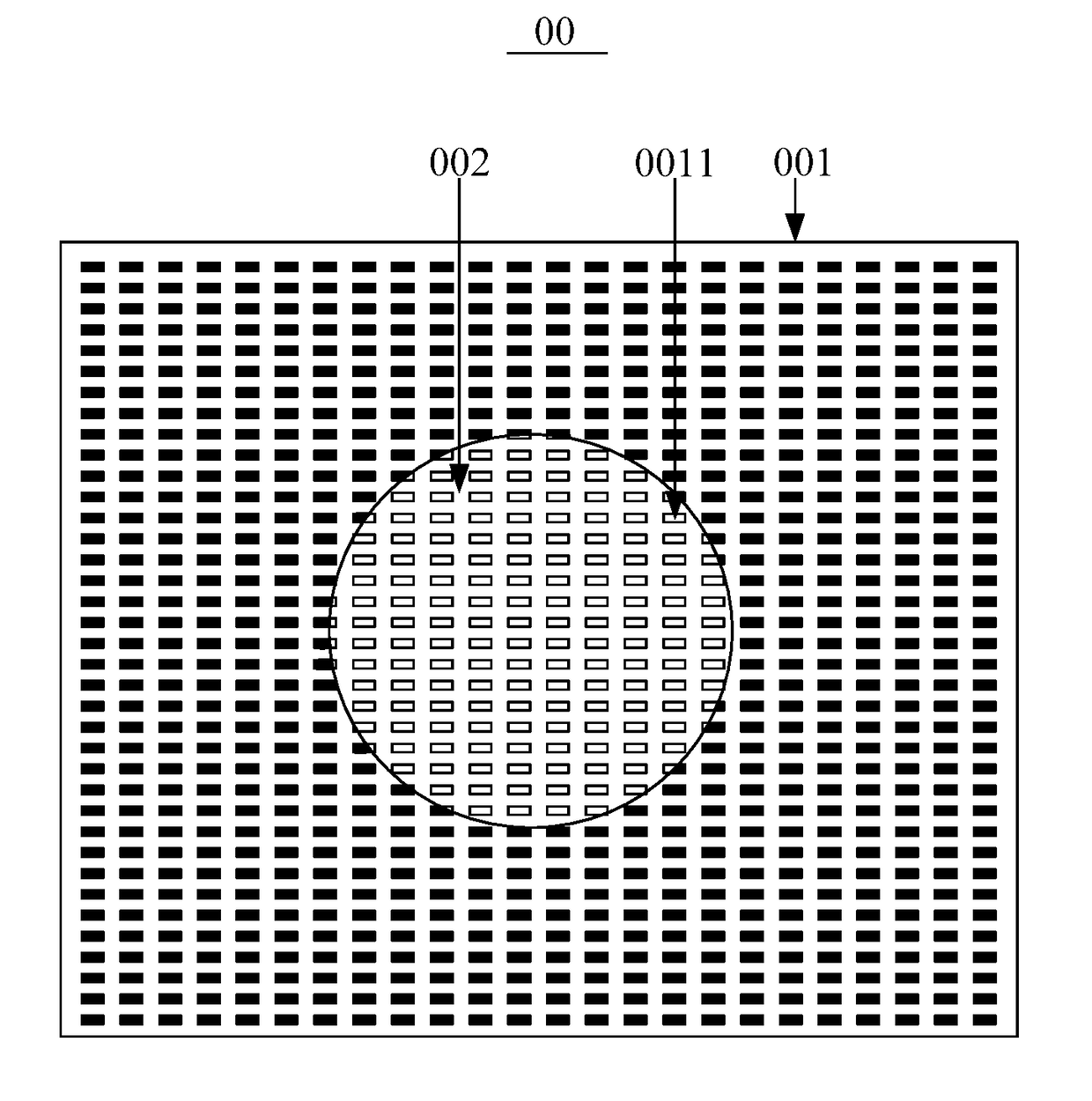

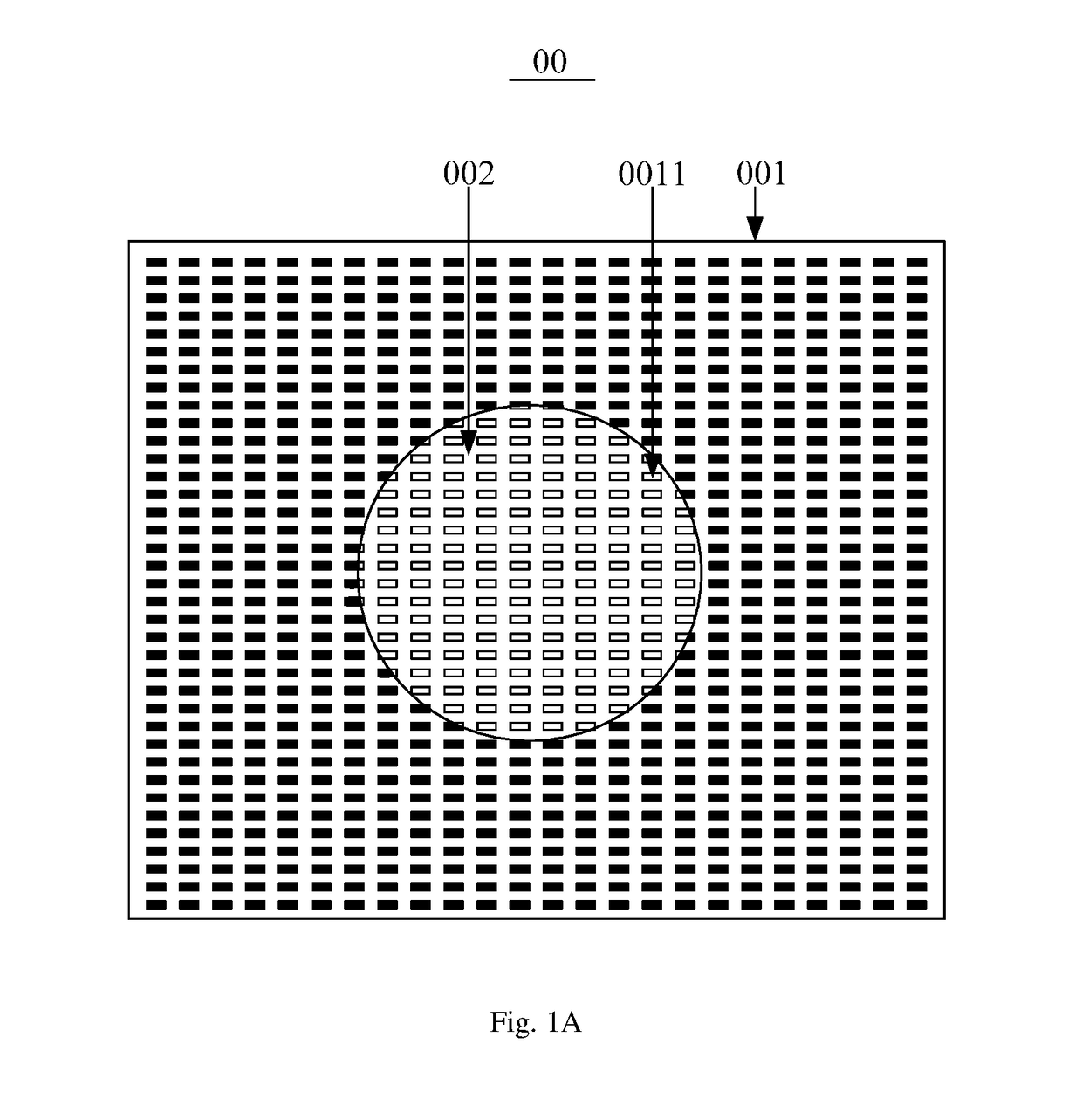

ActiveUS20180209028A1Reduce stress differentialVacuum evaporation coatingSolid-state devicesDisplay deviceEvaporation

The present disclosure provides a mask assembly and a method for manufacturing the same, and a display device. The mask assembly includes a frame, a first mask and a second mask, and the first mask and the second mask are superposed on the frame; the first mask includes an opening region, the second mask includes an evaporation region in which a first evaporation hole is provided for allowing an evaporation material to pass therethrough and a buffer region surrounding the evaporation region and configured to block off the evaporation material, and an orthographic projection of the boundary of the opening region onto the second mask is located within the buffer region.

Owner:BOE TECH GRP CO LTD +1

Coned disc spring

ActiveUS20150076756A1Reduce stress differentialNon-linear load characteristicsBelleville-type springsRing springsEllipseMechanical engineering

An elliptical coned disc spring can be accommodated in a rectangular installation space, can yield non-linear load characteristics, and can reduce stress differences between a bending part at a long radial part side and a bending part at a short radial part side. An elliptical coned disc spring has a body in which an outer circumference is an ellipse in a disc shape. A hole is formed at the center of the body. The hole may have various shapes such as a circle, an ellipse, etc. The body has a long radial part 111 and a short radial part. A plate width of the long radial part is set to be greater than a plate width of the short radial part (that is, a>b).

Owner:NHK SPRING CO LTD

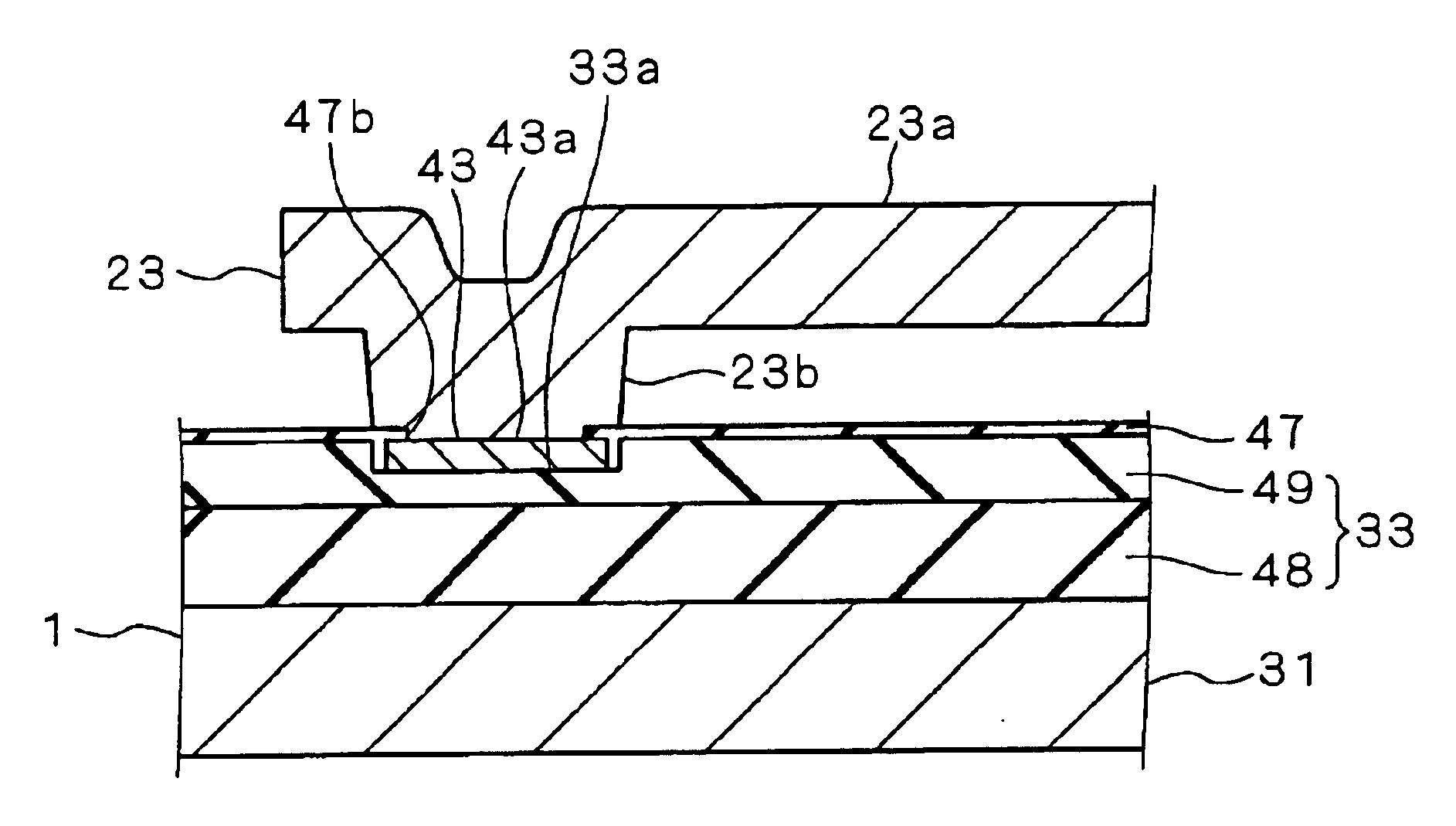

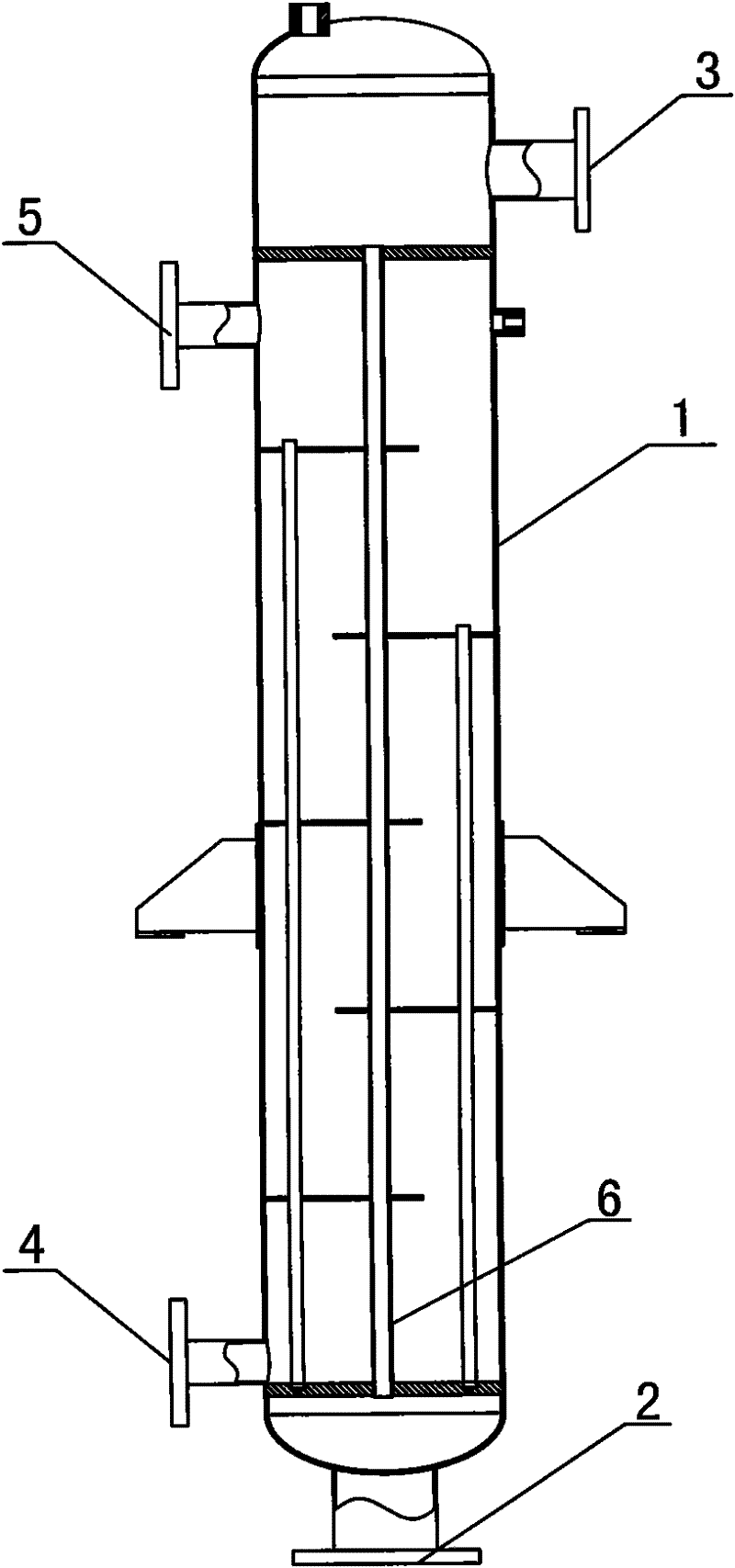

Substrate and method for producing the same, and thin film structure

InactiveUS6900071B2Reduce stress differentialShorten the timeAcceleration measurement using interia forcesSemiconductor/solid-state device manufacturingSiliconFilm structure

A substrate is provided with a substrate main body made from silicon, and an oxide film for a base formed thereon. The oxide film includes a first oxide film made mainly of a thermal SiO2 film formed by thermally oxidizing silicon in the substrate main body, and a second oxide film made of a high-temperature oxide film deposited and formed thereon. Alternatively the second oxide film may be formed by TEOS.

Owner:MITSUBISHI ELECTRIC CORP

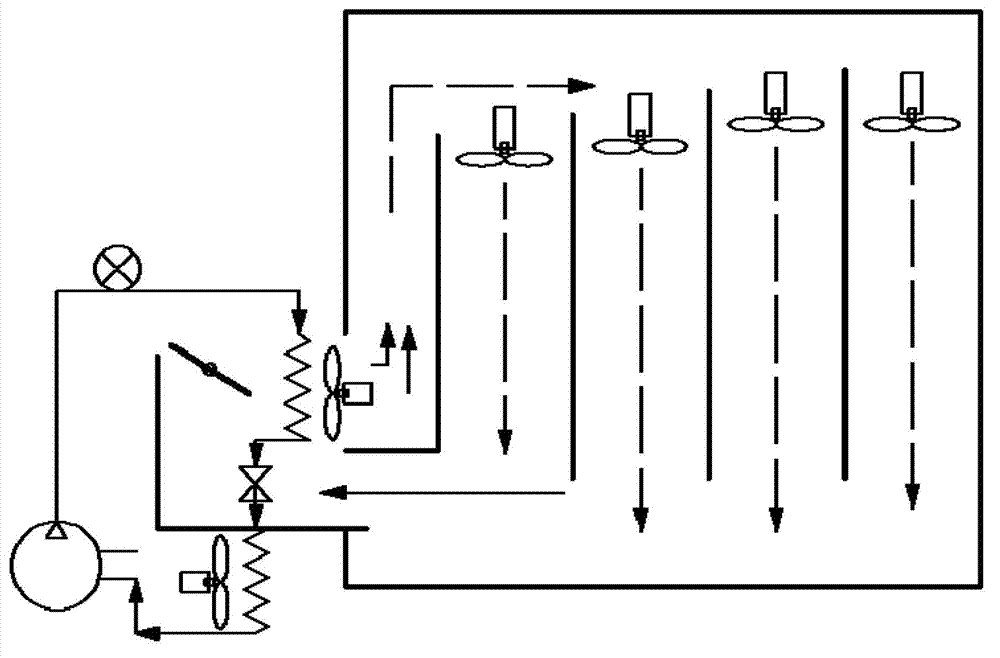

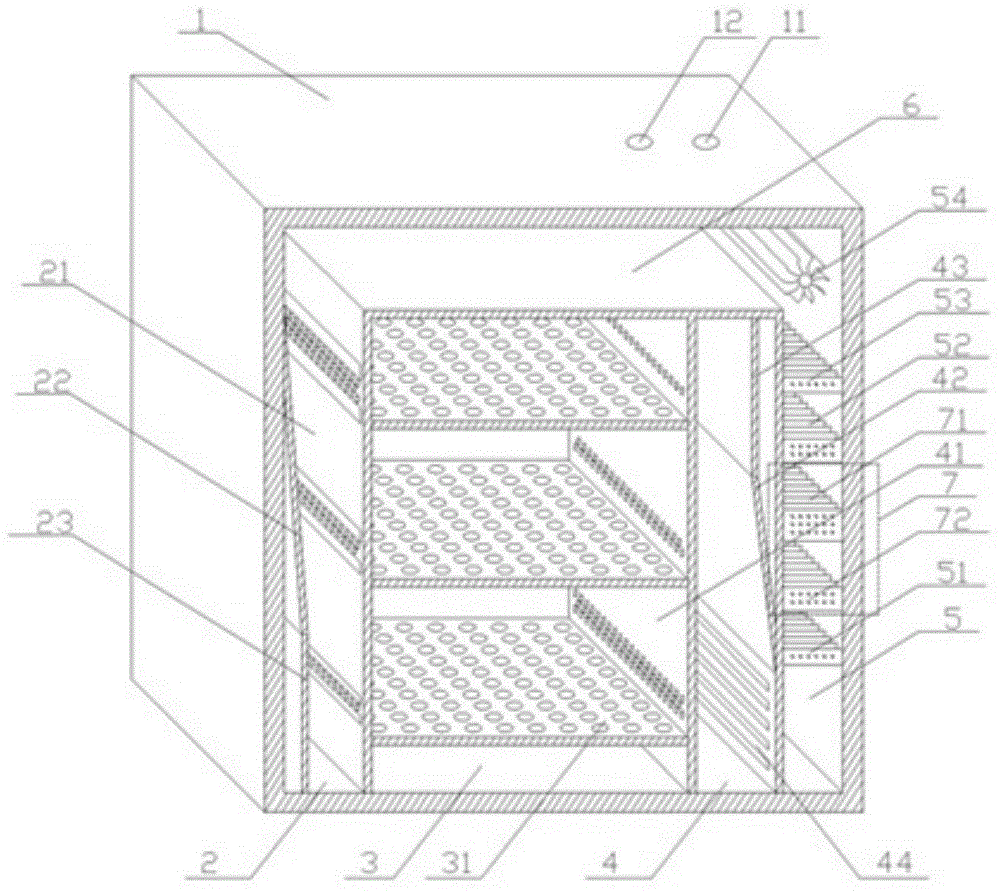

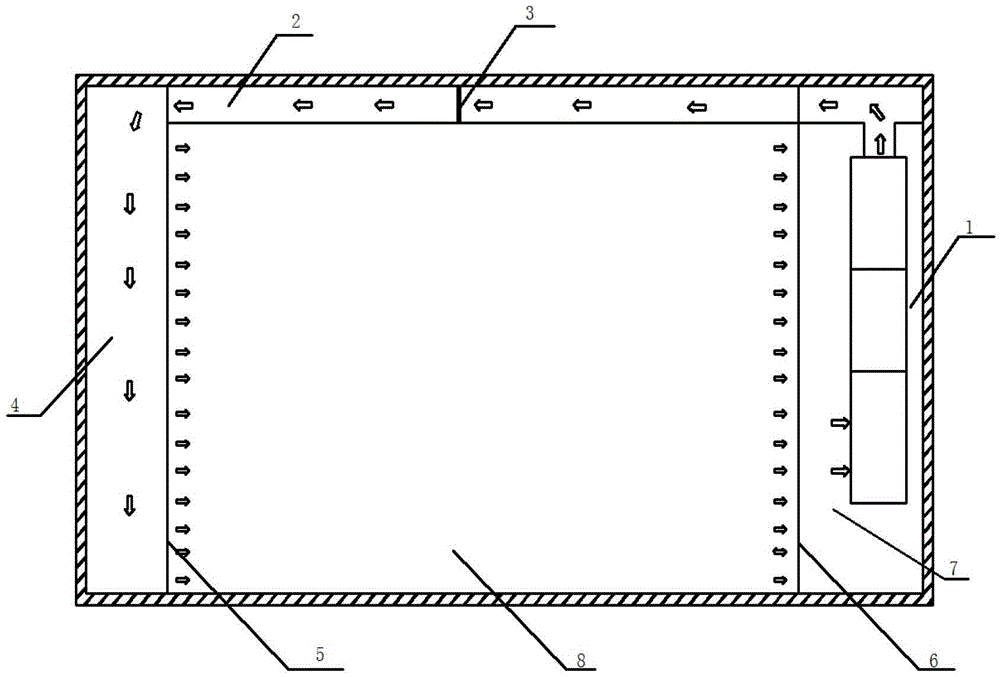

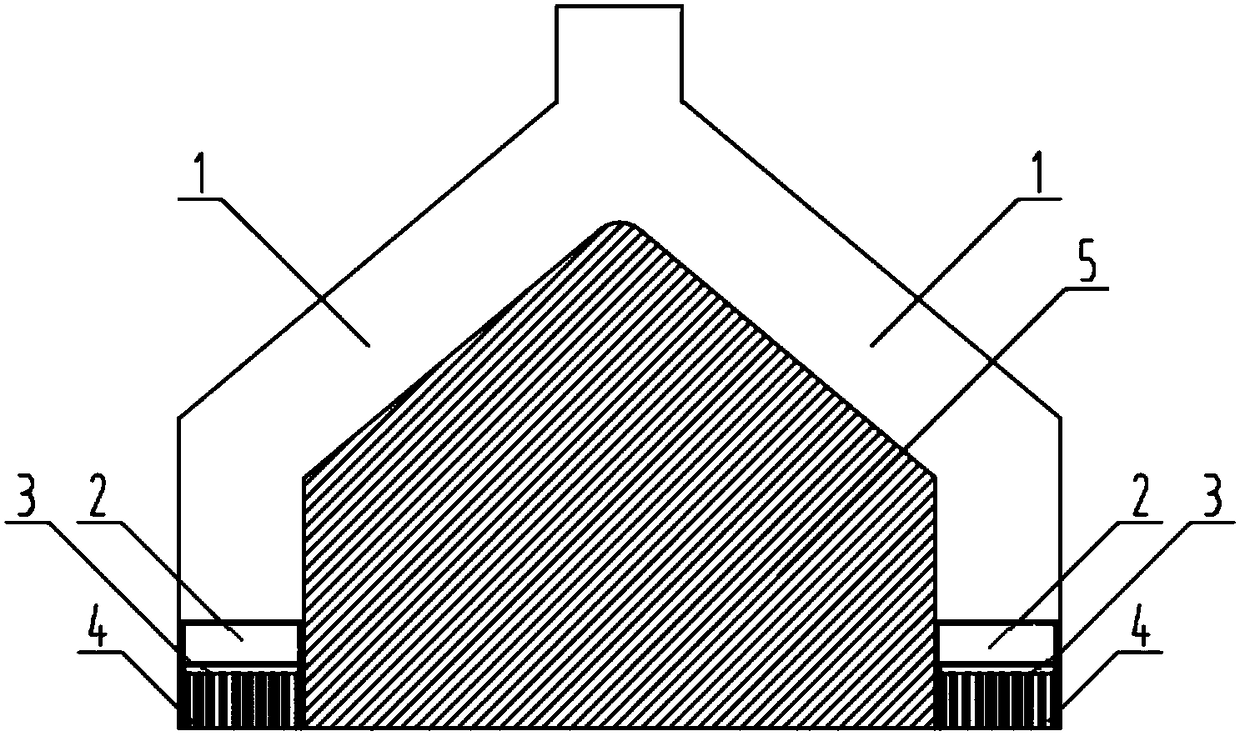

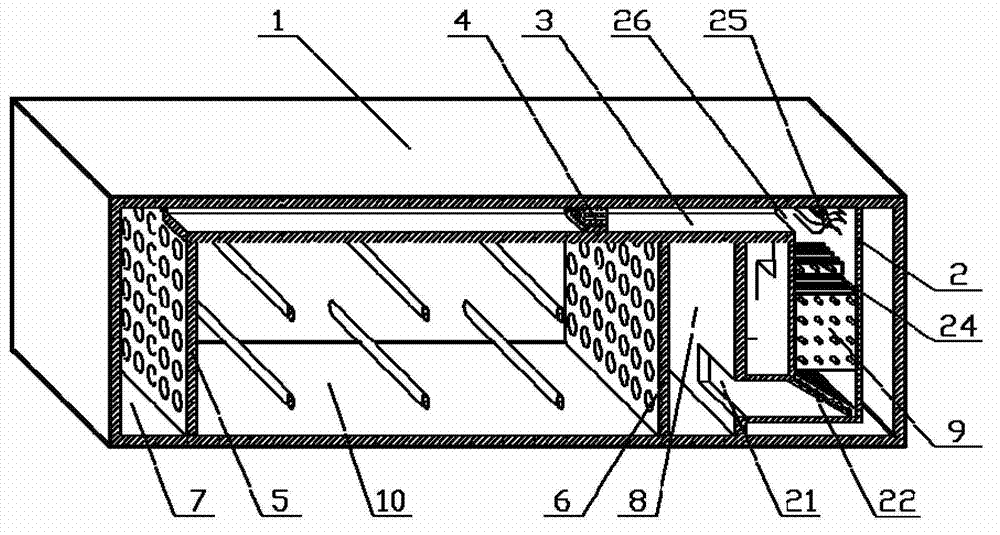

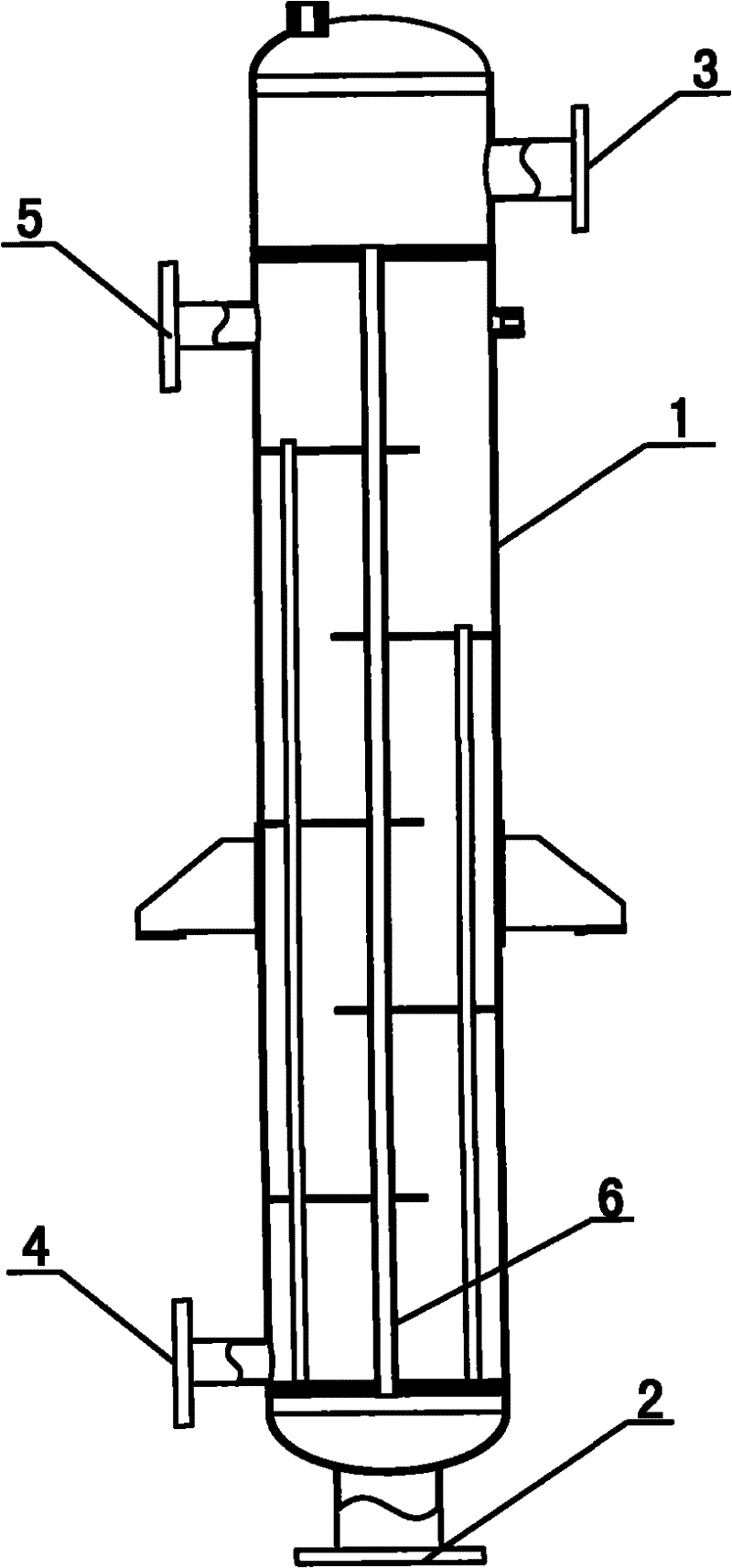

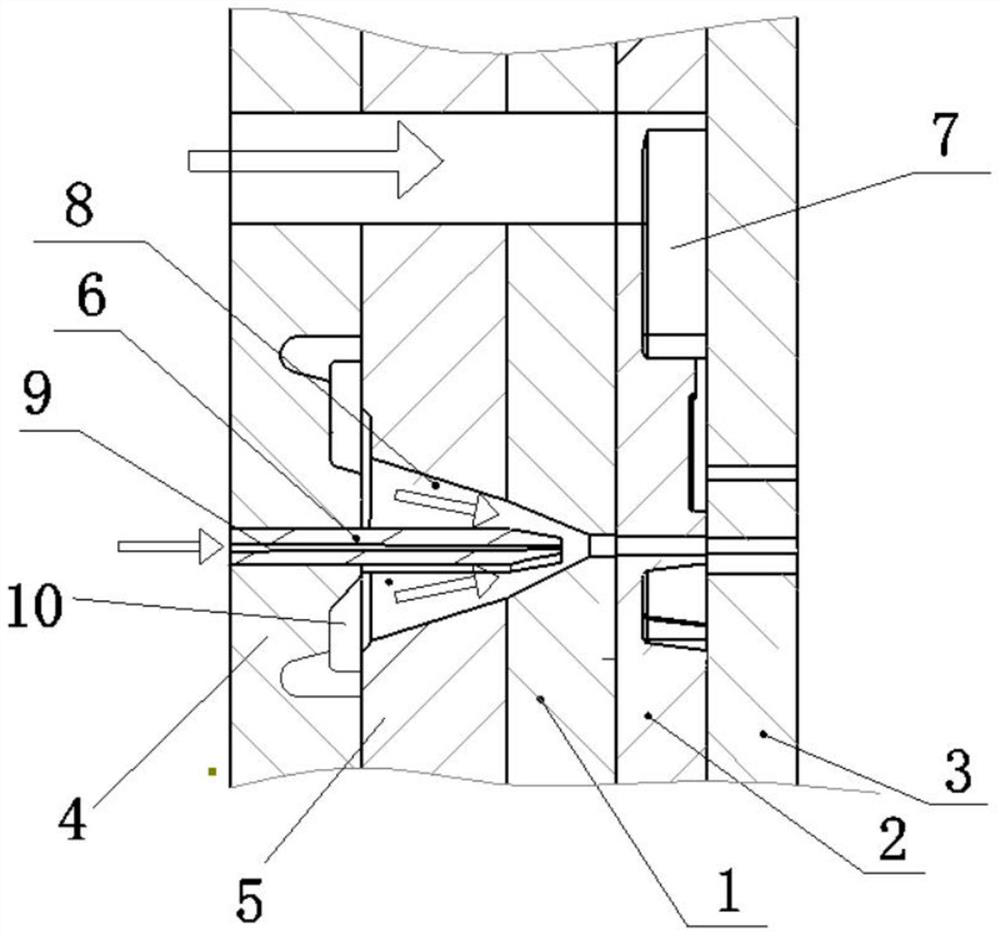

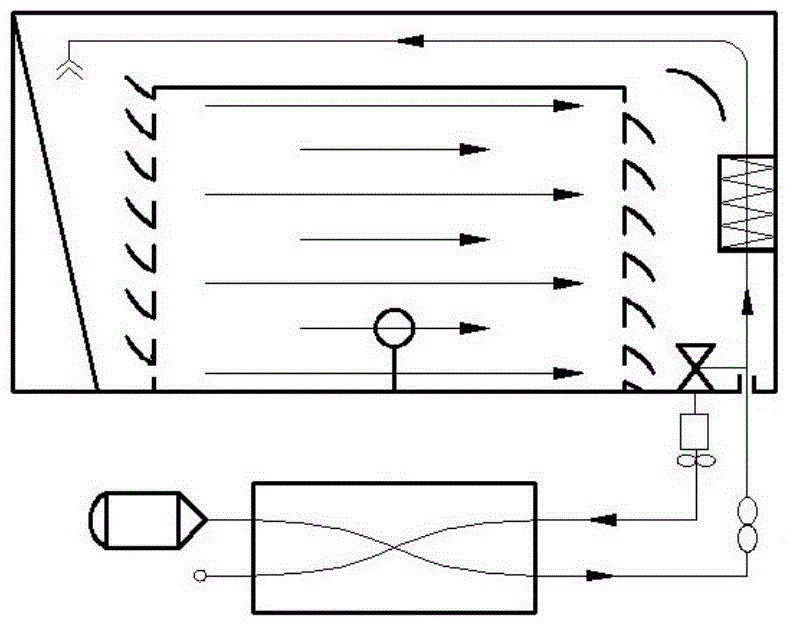

Drying surface parallel air supply type domestic fungus heat pump drying apparatus

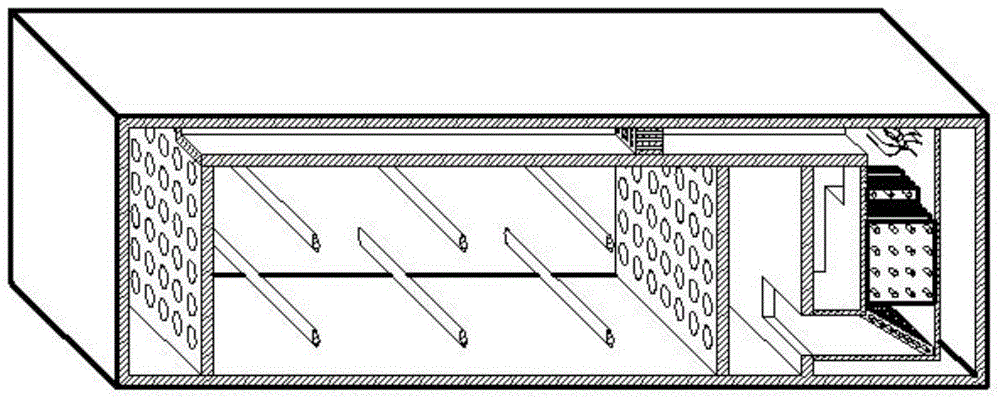

ActiveCN105028611AEmission reductionIncrease profitFood processingFruits/vegetable preservation by dehydrationVena contracta diameterAir treatment

The invention discloses a drying surface parallel air supply type domestic fungus heat pump drying apparatus. The apparatus comprises an enclosing structure, a variable cross section air supply static pressure space, a drying area, a variable cross section air return static pressure space, an air treatment device, and an air supply main tube arranged at the upper portion of the enclosing structure, an air supply non-uniform orifice plate and an air return non-uniform orifice plate which are vertically arranged divide a space below the air supply main tube into the variable cross section air supply static pressure space, the drying area and the variable cross section air return static pressure space which are sequentially arranged along the airflow direction, and the air treatment device is arranged at the outer side of the variable cross section air supply static pressure space; and a group of air supply holes and a group of air return holes are arranged above each of layers of storage plates arranged in the drying area. Drying surface parallel air supply is adopted to improve the drying airflow distribution, so the uniformity and the stability of airflow in the drying surface are guaranteed, the drying efficiency is improved, and energy consumption is reduced.

Owner:NANJING NORMAL UNIVERSITY +1

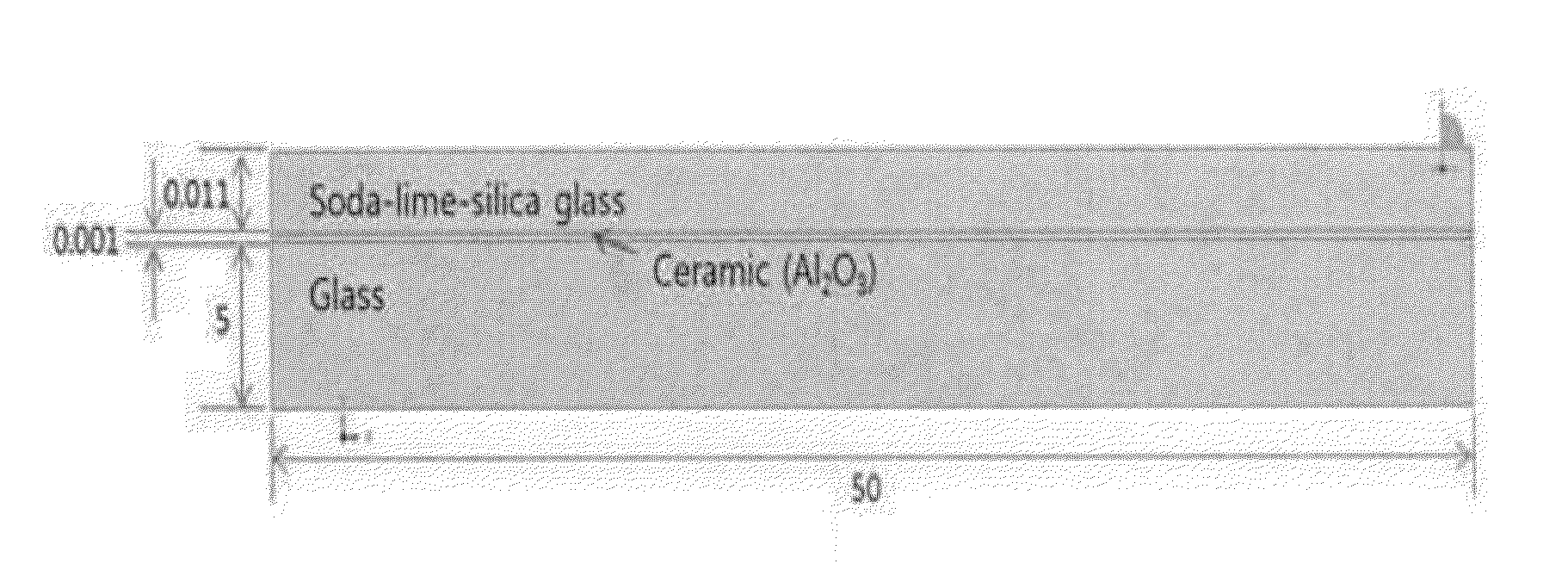

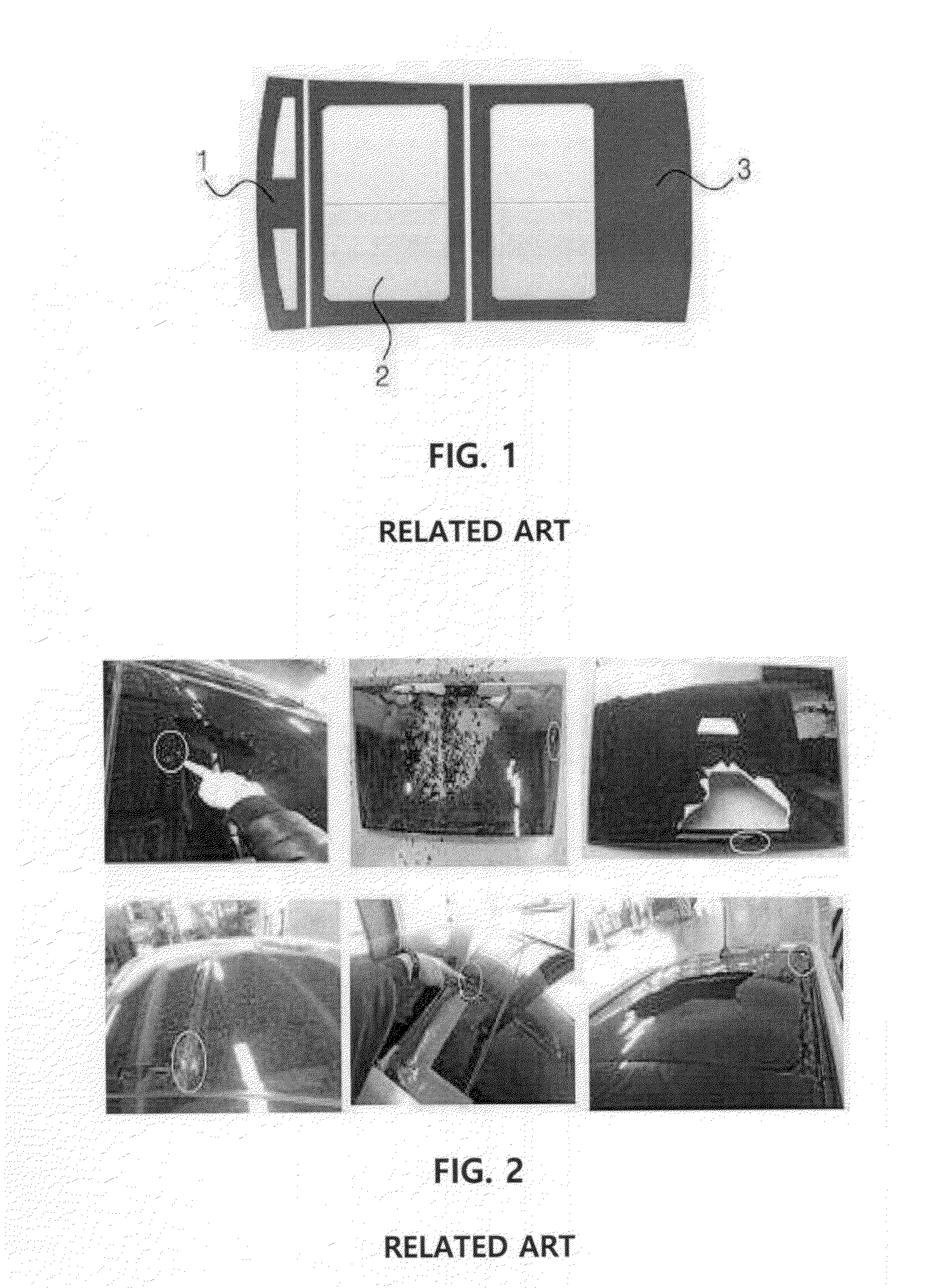

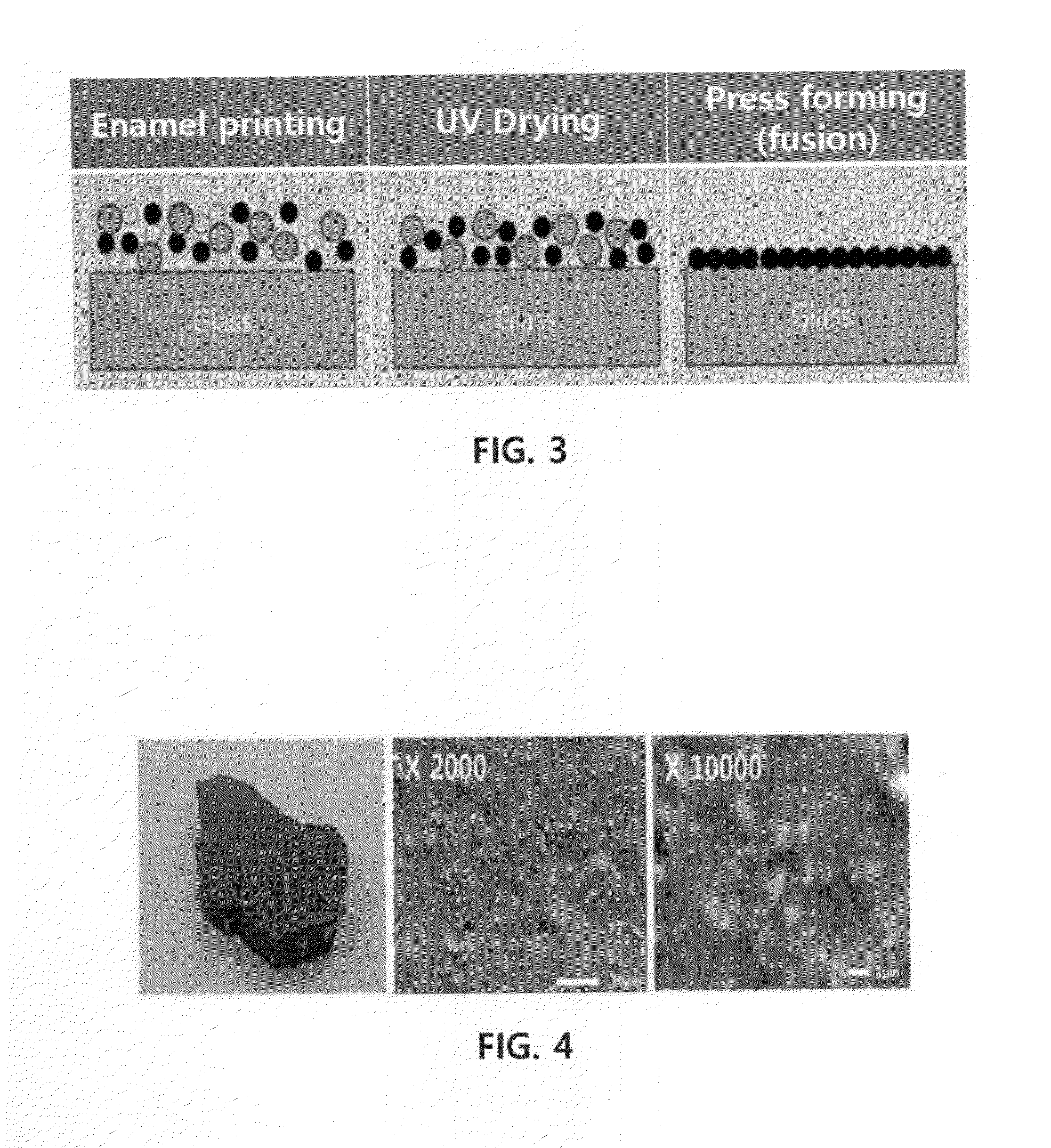

Buffer layer for preventing breakage of glass panel for panoramic sunroof, glass panel comprising the same, and manufacturing method for the same

InactiveUS20160075595A1Reduce the overall heightAvoid breakingGlass/slag layered productsGlass reforming apparatusGlass sheetSunroof

The present invention relates to a buffer layer for preventing breakage in a panoramic sunroof glass panel, a glass panel including the buffer layer, and a manufacturing method for the glass panel, and more particularly, to a technique of preventing breakage in the region with a ceramic coating layer in a glass panel for panoramic sunroof by providing a physical / chemical / mechanical buffer layer between the tempered glass and the ceramic coating layer, while the ceramic coating layer is vulnerable to impact and likely to break.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

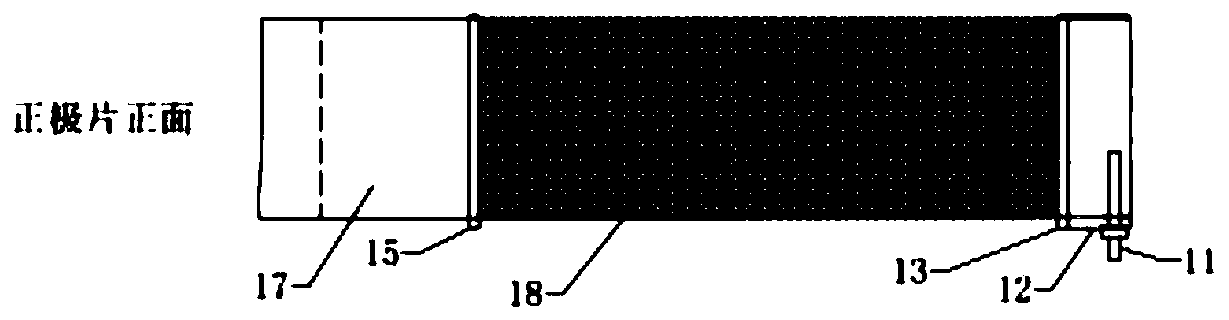

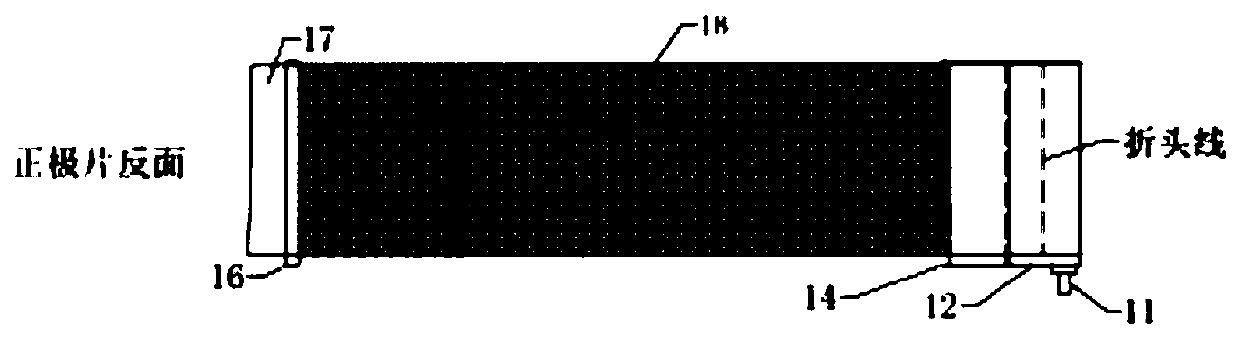

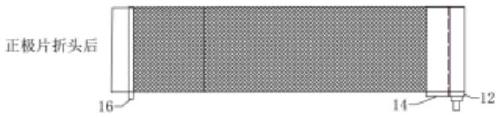

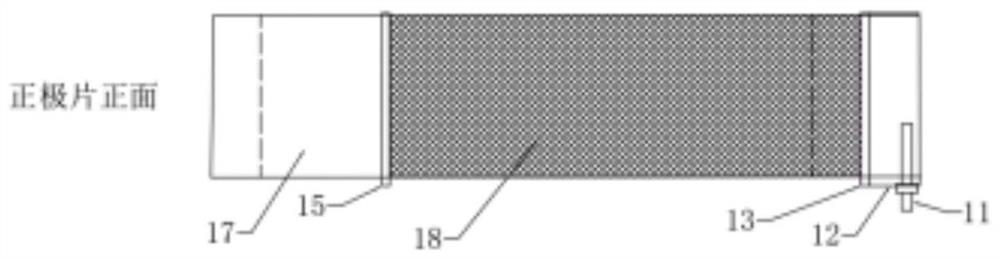

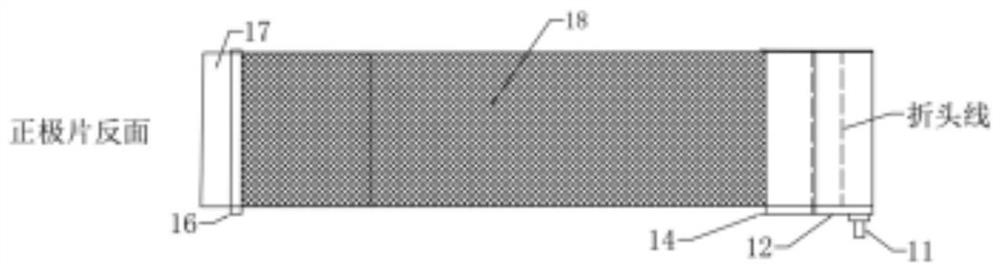

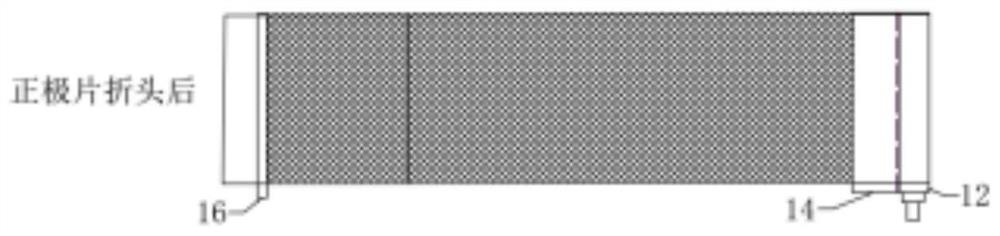

Method for improving local deformation of high-energy-density flexible package ion battery and battery

ActiveCN111463497AIncreasing the thicknessIncrease pressureFinal product manufactureSecondary cellsHigh energyPhysical chemistry

The invention provides a method for improving local deformation of a high-energy-density flexible package ion battery and the battery. The method comprises the following steps of setting parameters ofprotective glue, and adhering the protective glue to a positive plate and a negative plate according to the parameters of the protective glue; preparing a roll core by utilizing the positive plate and the negative plate adhered with the protective glue, and preparing the roll core into a battery cell according to a battery cell preparation process; carrying out formation operation of the batterycell by utilizing a high-temperature pressurizing formation cabinet, collecting the thicknesses of multiple positions of the battery cell in the formation operation process, and adjusting the pressureof a post-formation surface of the battery cell according to the thicknesses of the multiple positions of the battery cell; and calculating a free electrolyte coefficient of the formed battery cell,setting the vacuumizing time according to the free electrolyte coefficient, vacuumizing the formed battery cell according to the vacuumizing time, and preparing the lithium ion battery by utilizing the vacuumized battery cell. The method is advantaged in that local deformation of the battery can be obviously reduced, and use performance of the battery is enhanced.

Owner:山东聚信新能源科技有限公司

Line-edge roughness improvement for small pitches

ActiveUS8877641B2Reduce stress differentialDecorative surface effectsPhotomechanical apparatusEtchingEngineering

A method for mitigating line-edge roughness on a semiconductor device. The method includes line-edge roughness mitigation techniques in accordance with embodiments of the present invention. The techniques include: reducing the SiON film thickness below a conventional thickness; increasing the photoresist thickness above a conventional thickness; etching the SiON film with an etch bias power less than a conventional wattage amount with an overetch percentage less than a conventional overetch percentage; removing the SiON film layer immediately after completion of the amorphous carbon film layer etching; and lowering the lower electrode temperature below a conventional temperature.

Owner:SPANSION LLC

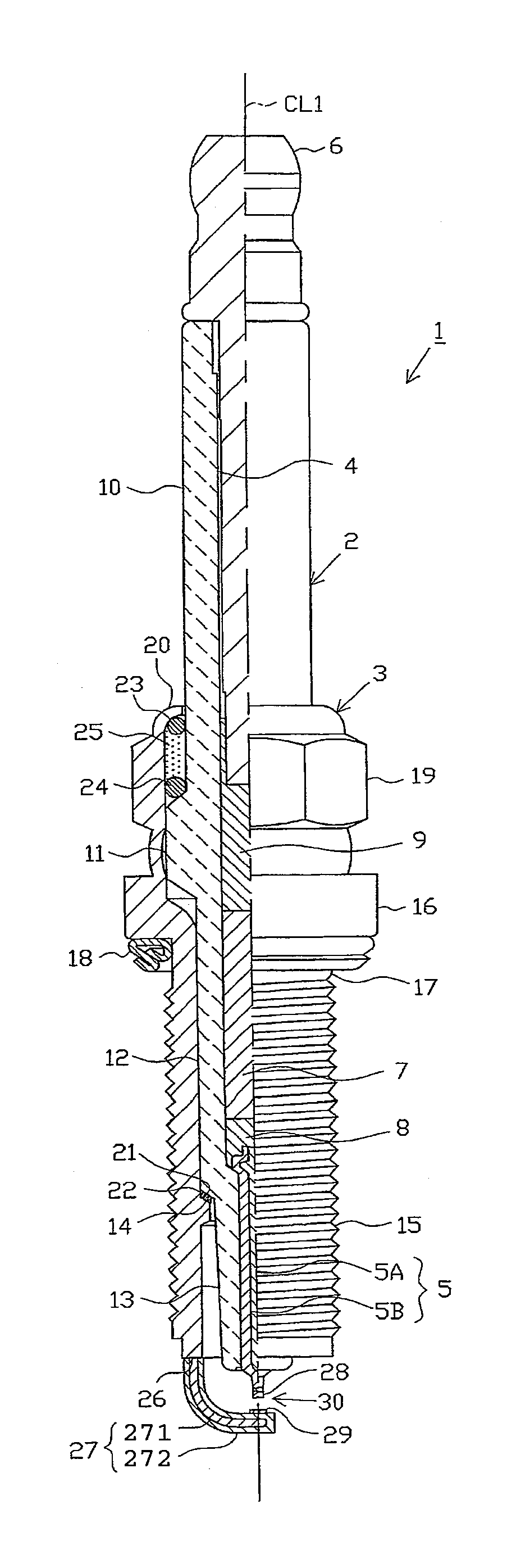

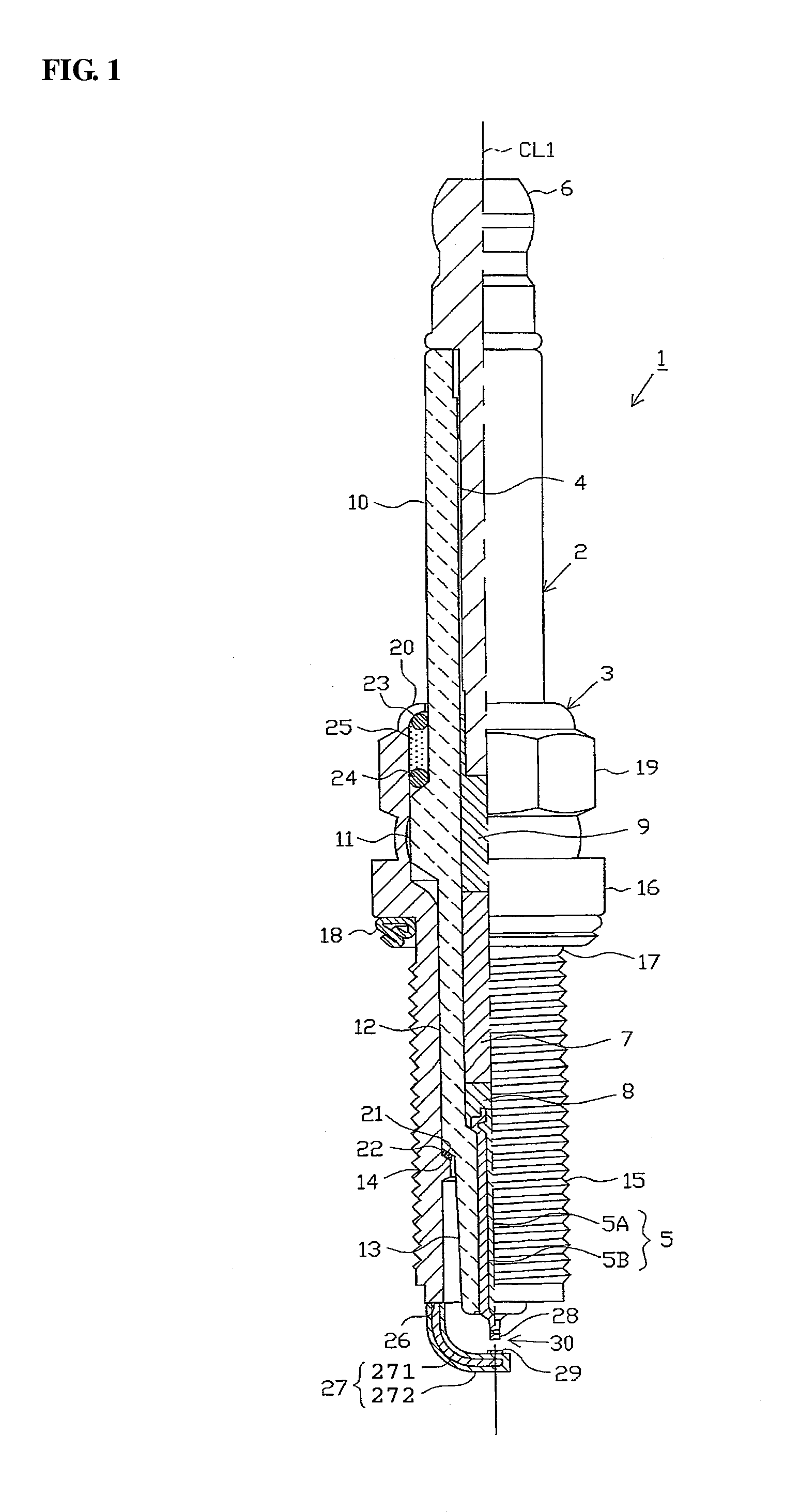

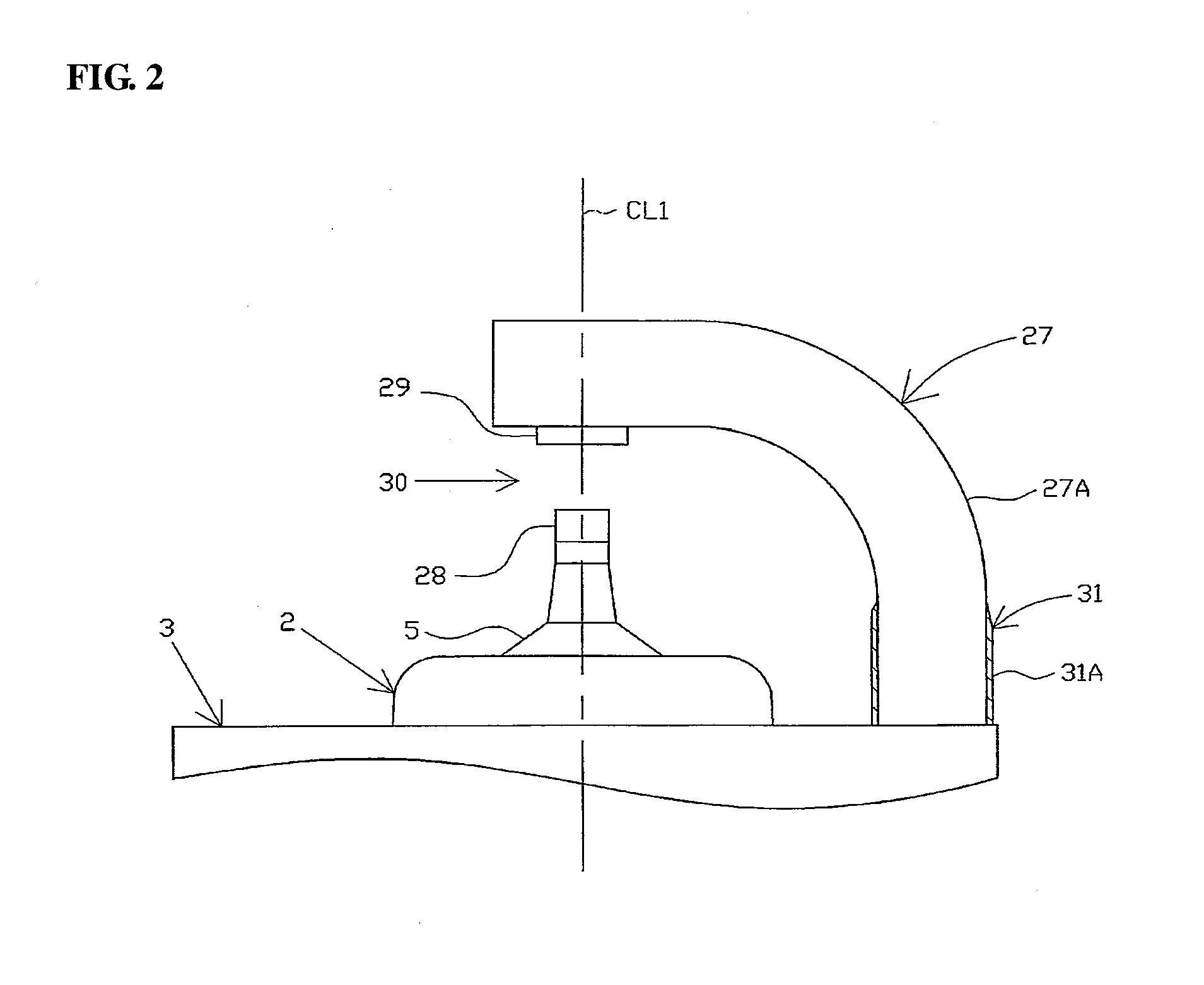

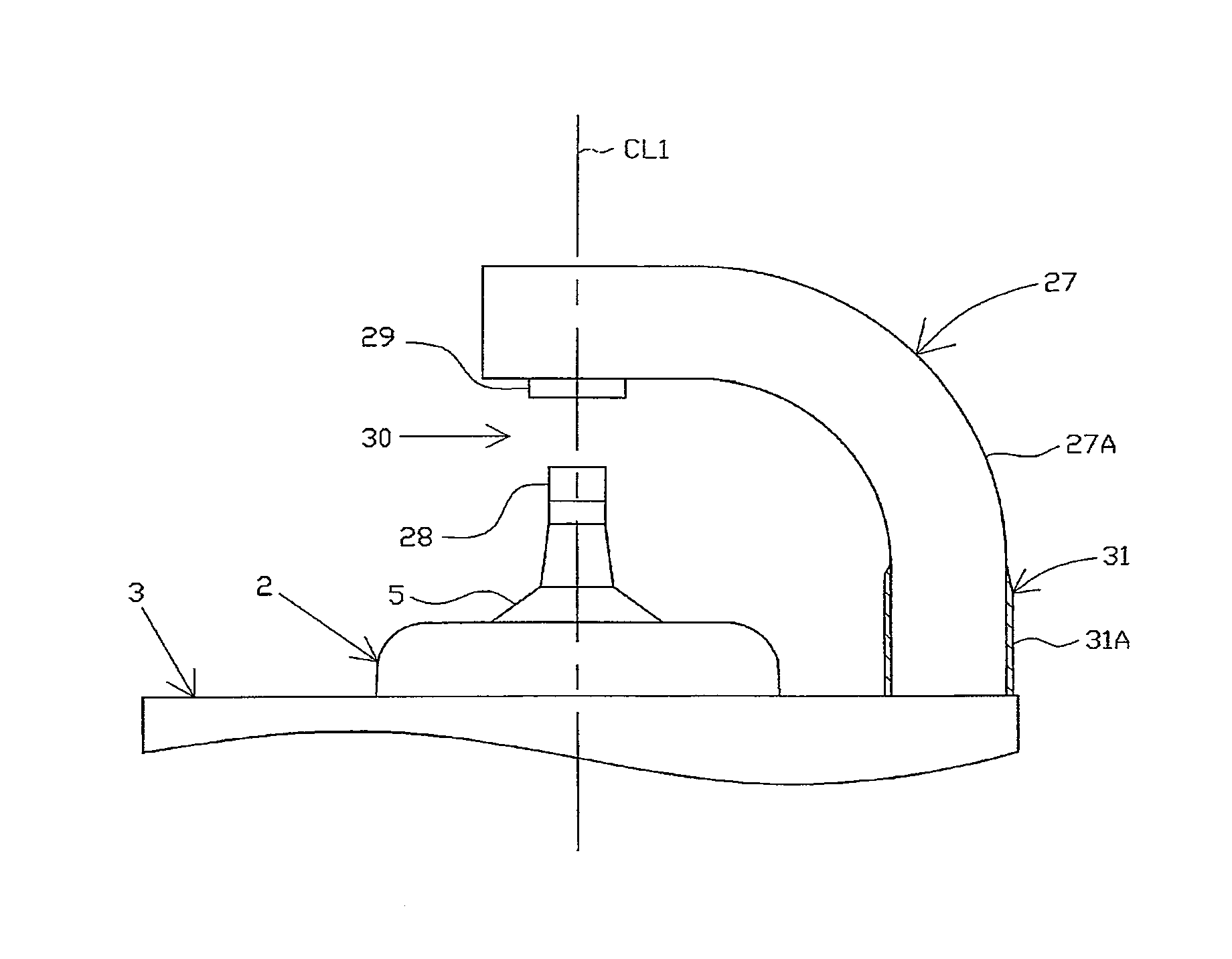

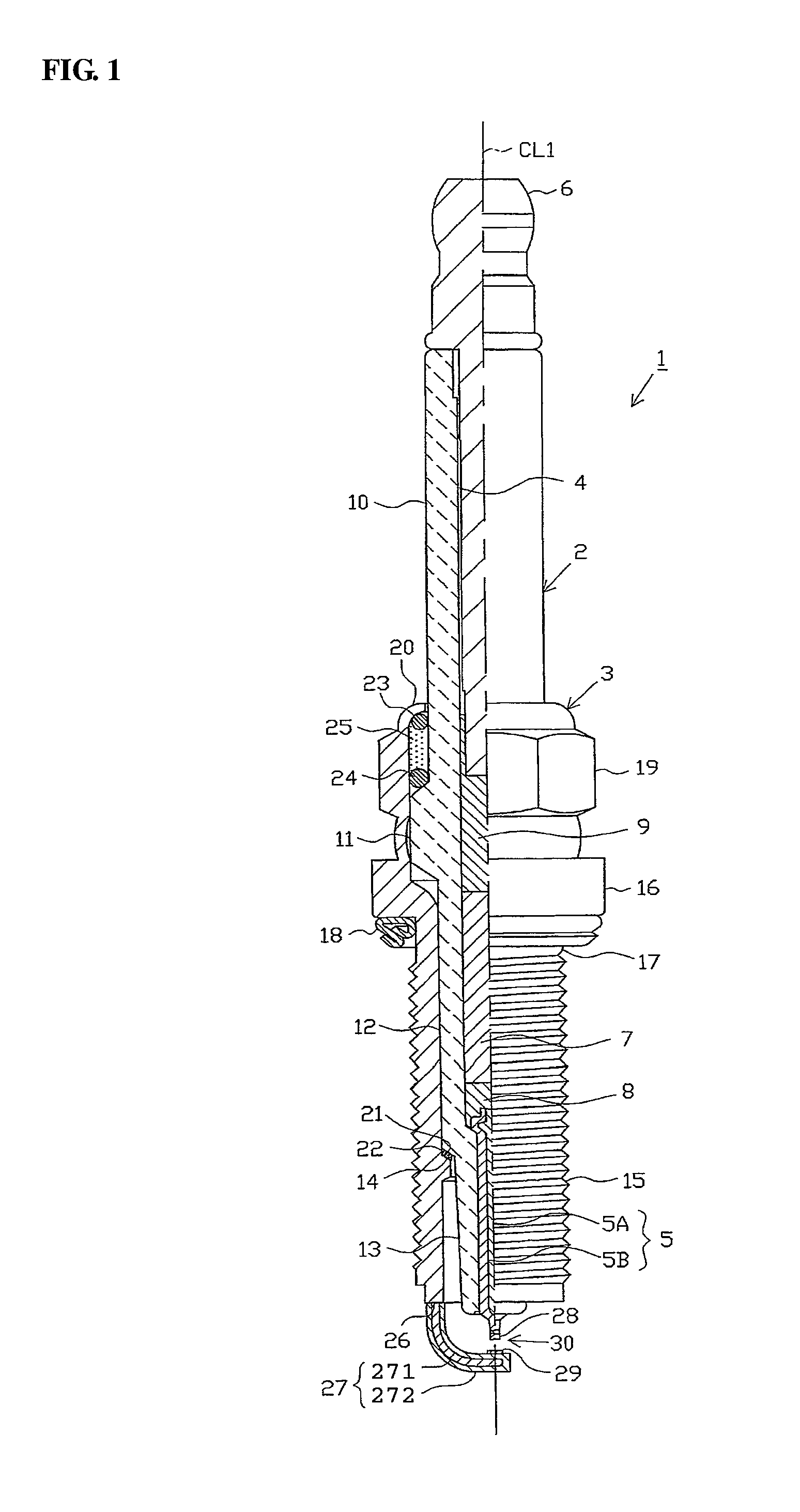

Spark plug

A spark plug includes a metal shell, a ground electrode joined to a front end portion of the metal shell and a nickel layer formed on the ground electrode, wherein the ground electrode has a base material exposed region in which a base material of the ground electrode is exposed; and wherein the nickel layer includes an outer-lateral-side nickel layer located on an outer lateral surface of the ground electrode at a position adjacent to the base material exposed region and satisfies a condition of LA≧25 μm, where LA is a length from a first part of the outer-lateral-side nickel layer having a thickness equal to 80% of a maximum thickness of the outer-lateral-side nickel layer to a second part of the outer-lateral-side nickel layer having a thickness equal to 20% of the maximum thickness of the outer-lateral-side nickel layer in a longitudinal direction of the ground electrode.

Owner:NGK SPARK PLUG CO LTD

Spark plug

ActiveUS8946976B2Avoid separationReduce stress differentialSparking plugsFuel injection apparatusMetalGrounding electrodes

A spark plug includes a metal shell, a ground electrode joined to a front end portion of the metal shell and a nickel layer formed on the ground electrode, wherein the ground electrode has a base material exposed region in which a base material of the ground electrode is exposed; and wherein the nickel layer includes an outer-lateral-side nickel layer located on an outer lateral surface of the ground electrode at a position adjacent to the base material exposed region and satisfies a condition of LA≧25 μm, where LA is a length from a first part of the outer-lateral-side nickel layer having a thickness equal to 80% of a maximum thickness of the outer-lateral-side nickel layer to a second part of the outer-lateral-side nickel layer having a thickness equal to 20% of the maximum thickness of the outer-lateral-side nickel layer in a longitudinal direction of the ground electrode.

Owner:NGK SPARK PLUG CO LTD

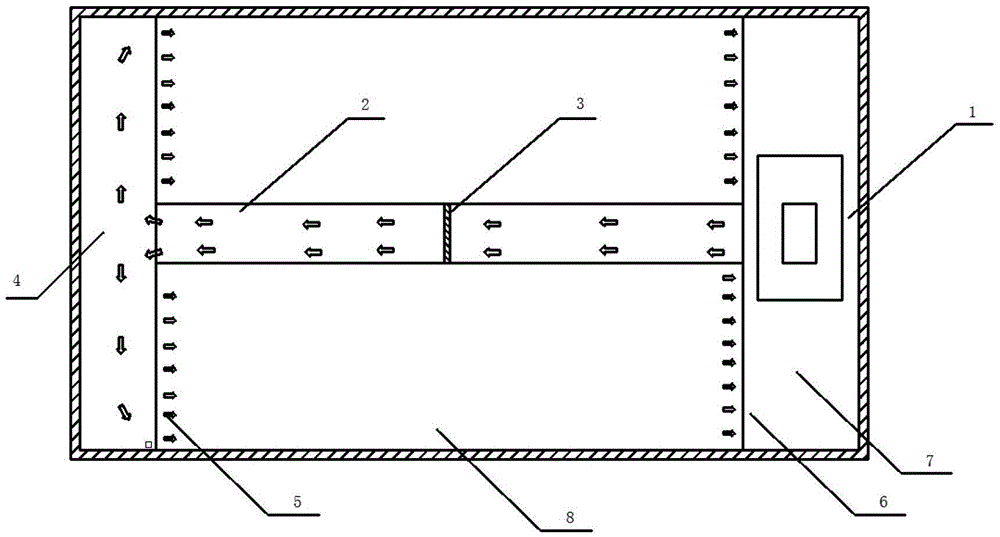

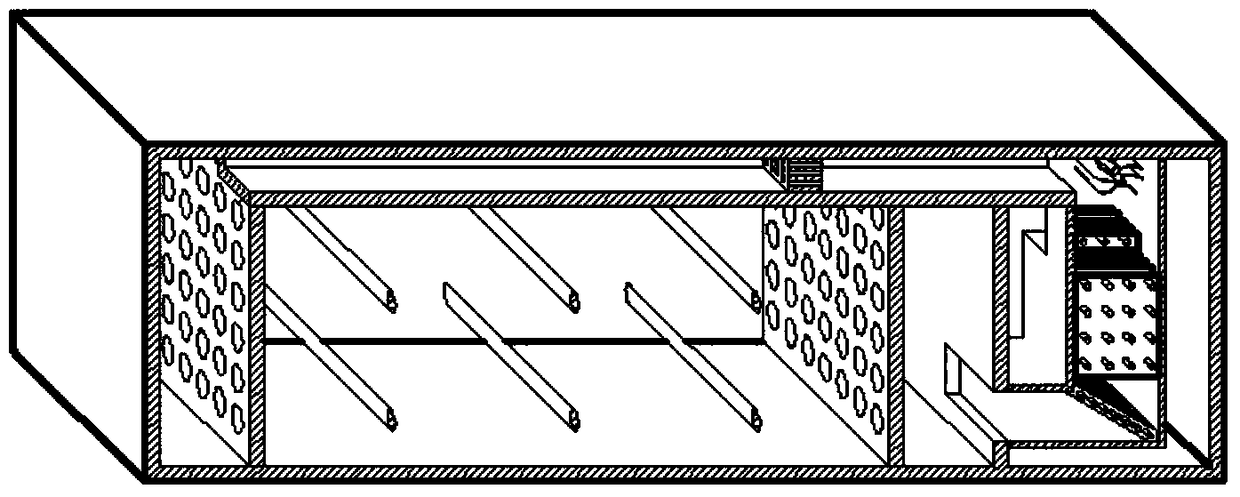

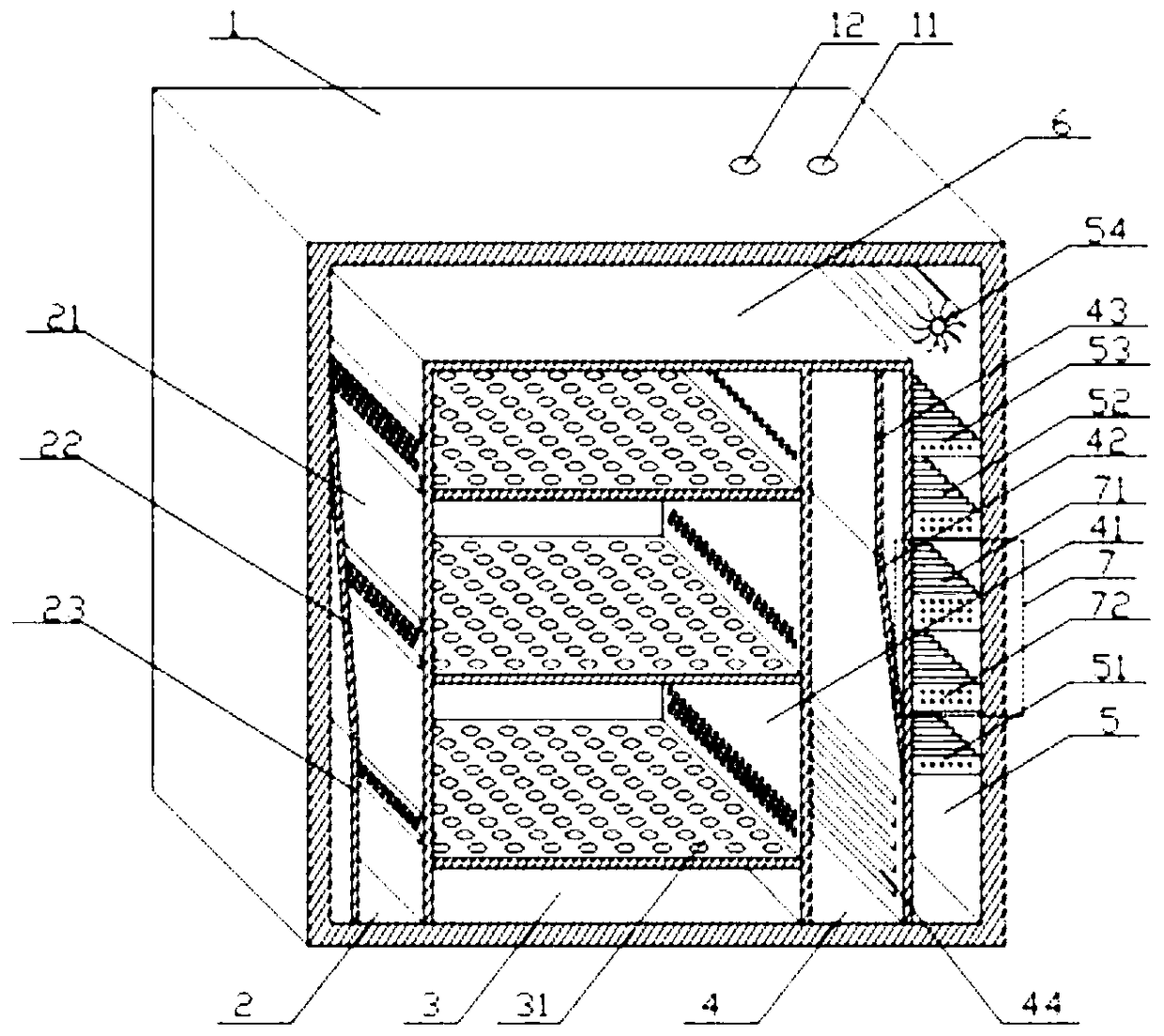

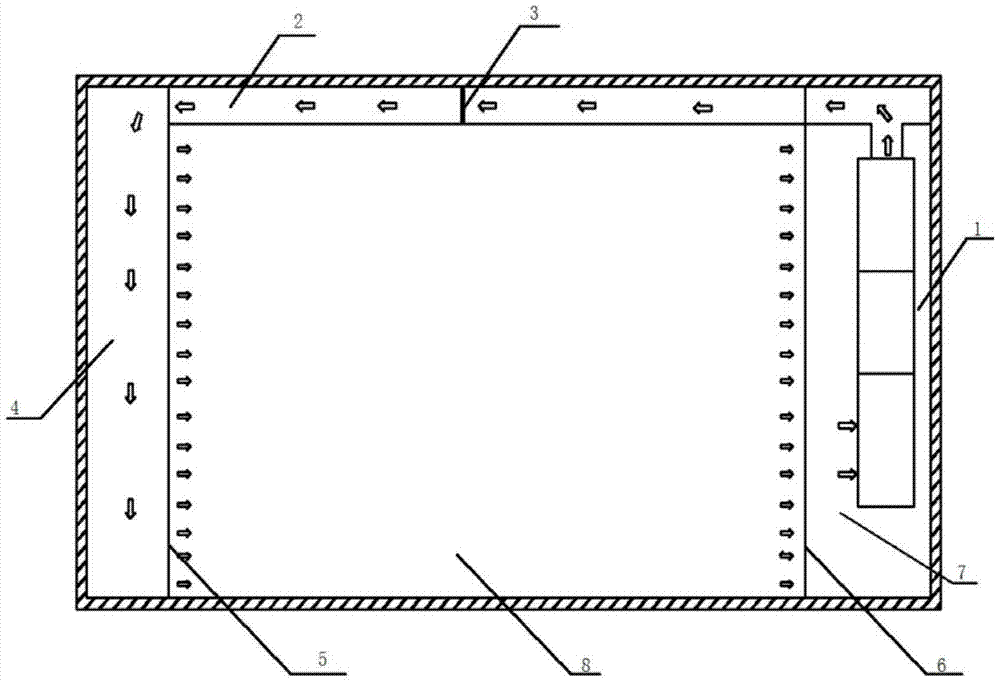

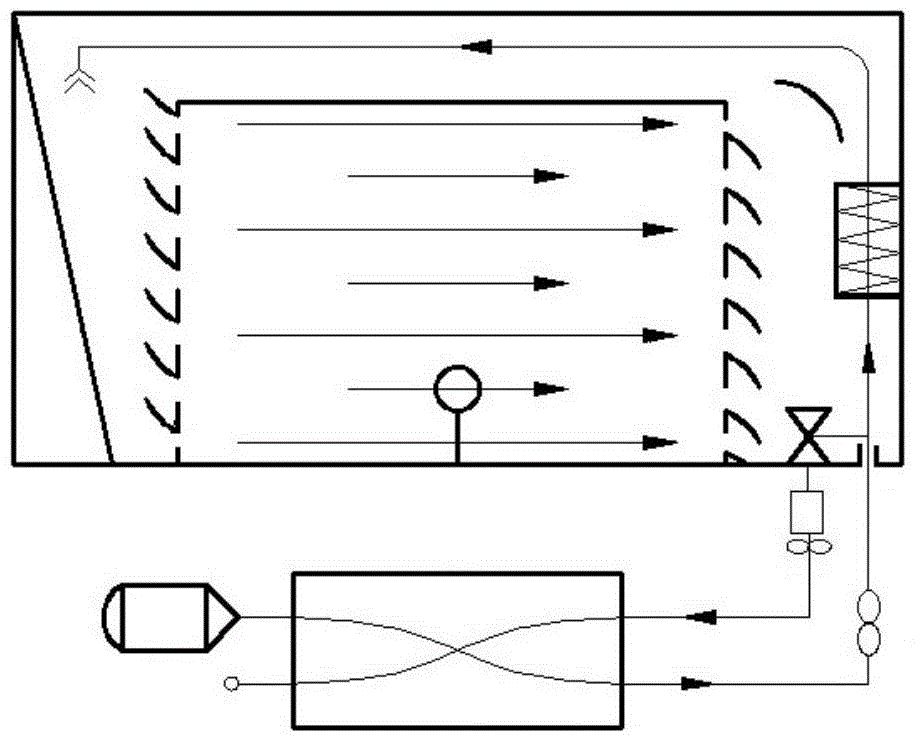

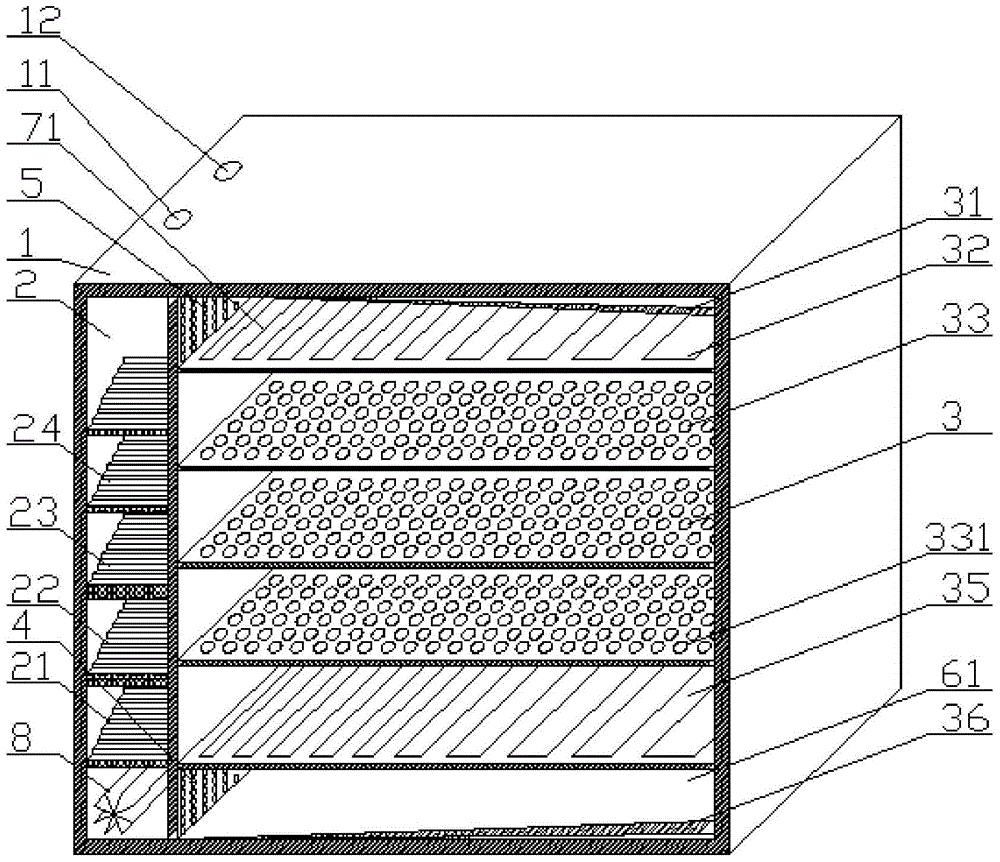

A performance test device for a food refrigerator

ActiveCN103217310BIncrease humidityEven air distributionStructural/machines measurementThermodynamicsAir velocity

The invention discloses a performance testing device for a food refrigerator, which comprises a box body, a top cover of the box body, an air handling unit, an air supply main pipe, an air mixing device, and an air supply orifice plate and a return air orifice plate arranged in parallel in the box body. The air orifice plate and the return air orifice divide the box into three areas, which are the air supply static pressure space and the return air static pressure space on both sides, and the test environment room in the middle; the air handling unit is located in the return air static pressure space Among them, the air handling unit communicates with the air supply static pressure space through the air supply main pipe, and the air mixing device is arranged in the air supply main pipe pipeline. The present invention adopts the way of parallel air supply to improve the airflow organization, which can ensure the uniformity and stability of the air flow and temperature and humidity in the test room during the test, can truly simulate the normal working environment of the food freezer, and ensure that the temperature, humidity and wind speed distribution in the test room reach JB / T ? 7244-1994 "Food Freezer" series standard requirements.

Owner:NANJING NORMAL UNIVERSITY +1

Preparation process of mesophase pitch based protofilament continuous filament

InactiveCN108385179AReduce wire breakageReduce void defectsSpinning solution filteringSpinning solution de-aeratingFiber bundleGas bubble

The invention discloses a preparation process of a mesophase pitch based a protofilament continuous filament. The preparation process comprises the following steps of sending mesophase pitch into a screw extruder through a feeder; heating, by a screw of the extruder, the mesophase pitch, and carrying out reduced pressure deaeration when the screw runs; conveying, by the screw extruder, a melted and deaerated melt into a spinning component through a metering pump, spreading the melt into a spinneret through a spure spreader of the spinning component, and extruding through spinneret orifices ofthe spinneret to carry out spinning; oiling an extrusion-molded fiber bundle, drawing by a drawing roll, and then collecting the filament. A reduced pressure deaeration opening in the preparation process is located behind a final zone; on one hand, the melt in a melting zone can be prevented from being evacuated and broken down to cause that a suction gas is dissolved in the melt. The mesophase pitch is completely molten after passing through a screw melting zone, and is uniformly mixed under the shearing action of a twin screw to be capable of forming a layer of thin and uniform melt in a tank; at the moment, gas bubbles in the interior of the melt can be completely separated through the reduced pressure deaeration. The preparation process is good in production efficiency, and moreover, the prepared mesophase pitch based protofilament is good in performance.

Owner:西安天运新材料科技有限公司

Mask assembly and method for manufacturing the same and display device

ActiveUS10648070B2Reduce stress differentialVacuum evaporation coatingSolid-state devicesDisplay deviceEngineering

The present disclosure provides a mask assembly and a method for manufacturing the same, and a display device. The mask assembly includes a frame, a first mask and a second mask, and the first mask and the second mask are superposed on the frame; the first mask includes an opening region, the second mask includes an evaporation region in which a first evaporation hole is provided for allowing an evaporation material to pass therethrough and a buffer region surrounding the evaporation region and configured to block off the evaporation material, and an orthographic projection of the boundary of the opening region onto the second mask is located within the buffer region.

Owner:BOE TECH GRP CO LTD +1

Sputtering target

InactiveUS9437486B2Easy to oxidizeHigh resistivityVacuum evaporation coatingSputtering coatingMetallurgyInterconnection

A sputtering target contains high purity Nb of which Ta content is 3000 ppm or less and oxygen content is 200 ppm or less. Dispersion of the Ta content in all the sputtering target is within ±30% as a whole target. Dispersion of the oxygen content is within ±80% as a whole target. According to such sputtering target, an interconnection film of low resistivity can be realized. In addition, each grain of Nb in the sputtering target has a grain diameter in the range of 0.1 to 10 times an average grain diameter and ratios of grain sizes of adjacent grains are in the range of 0.1 to 10. According to such sputtering target, giant dust can be largely suppressed from occurring. The sputtering target is suitable for forming a Nb film as liner material of an Al interconnection.

Owner:KK TOSHIBA

A heat pump drying device for edible fungus with parallel air supply on the drying surface

ActiveCN105028611BReduce energy consumptionKeep dryFood processingFruits/vegetable preservation by dehydrationVena contracta diameterAir treatment

The invention discloses a drying surface parallel air supply type domestic fungus heat pump drying apparatus. The apparatus comprises an enclosing structure, a variable cross section air supply static pressure space, a drying area, a variable cross section air return static pressure space, an air treatment device, and an air supply main tube arranged at the upper portion of the enclosing structure, an air supply non-uniform orifice plate and an air return non-uniform orifice plate which are vertically arranged divide a space below the air supply main tube into the variable cross section air supply static pressure space, the drying area and the variable cross section air return static pressure space which are sequentially arranged along the airflow direction, and the air treatment device is arranged at the outer side of the variable cross section air supply static pressure space; and a group of air supply holes and a group of air return holes are arranged above each of layers of storage plates arranged in the drying area. Drying surface parallel air supply is adopted to improve the drying airflow distribution, so the uniformity and the stability of airflow in the drying surface are guaranteed, the drying efficiency is improved, and energy consumption is reduced.

Owner:NANJING NORMAL UNIVERSITY +1

Edible fungus dried air circulation treatment device

ActiveCN103202520BSuitable for dry conditionsWell organized airflowFood processingFood treatmentAir cycleRefrigerant distribution

The invention discloses an edible fungus dried air circulation treatment device which comprises a baking chamber, an air treatment unit, an air supply header pipe, an air mixing device, and an air supply pore plate and an air return pore plate which are arranged in the baking chamber in parallel, wherein the baking chamber is segmented into an air supply static pressure space, an air return static pressure space and a baking workshop; the air treatment unit consists of an air inlet, a solid adsorption and dehumidification device, a heat pump loop, a fan, an auxiliary electric heater and an air outlet; the heat pump loop consists of a condenser and three groups of compressors and an evaporator assembly which are arranged in parallel; and the compressors and the evaporator assembly comprise an expansion valve, an evaporator and compressors which are sequentially connected. By employing the parallel air supply mode and the general-branch-general-branch refrigerant distribution mode, the air distribution is improved, and the uniformity and stability of the air flow and temperature field in the baking chamber during operation are guaranteed, so that the consistency of the baking effect is guaranteed, and the energy consumption in the process of operating the baking chamber at a low load is reduced.

Owner:NANJING NORMAL UNIVERSITY +1

Lamination device for solar modules and lamination encapsulation method thereof

InactiveCN106972073BImprove the temperature field distributionImprove the uniformity of temperature field distributionFinal product manufactureLaminationHydraulic cylinderSilica gel

The present invention discloses a laminating apparatus for a solar assembly. The laminating apparatus comprises a substrate and a pressing plate; a hydraulic cylinder drives the pressing plate to move up and down, so that the substrate and the pressing plate can be pressed together; the bottom surface of the pressing plate is provided with a silica gel film; the surface of the substrate is provided with a plurality of pushing pins; a cushion is laid on the pushing pins; mounting holes are arranged formed in the substrate; the pushing pins are installed in the mounting holes through lifting rods; the bottoms of the lifting rods are provided with heat insulating sleeves; electric heating wires are arranged in the substrate; the bottoms of the mounting holes are provided with spiral oil guiding tubes; annular grooves are formed at the tops of the mounting holes; the edges of the pushing pins are provided with metal elastic sheets through first springs; the external sides of the metal elastic sheets are provided with silica gel dumping cushions; the edge of the pressing plate is provided with slide rails; a clamping block is slidingly arranged in each slide rail; each clamping block is connected with a corresponding first air cylinder; and the clamping blocks are fixedly held at the edge of the silica gel film. With the laminating apparatus of the invention adopted, defects in the prior art can be eliminated, and the heating and pressure uniformity of components in a laminating process can be improved, and the yield of products can be improved.

Owner:江苏盐芯微电子有限公司

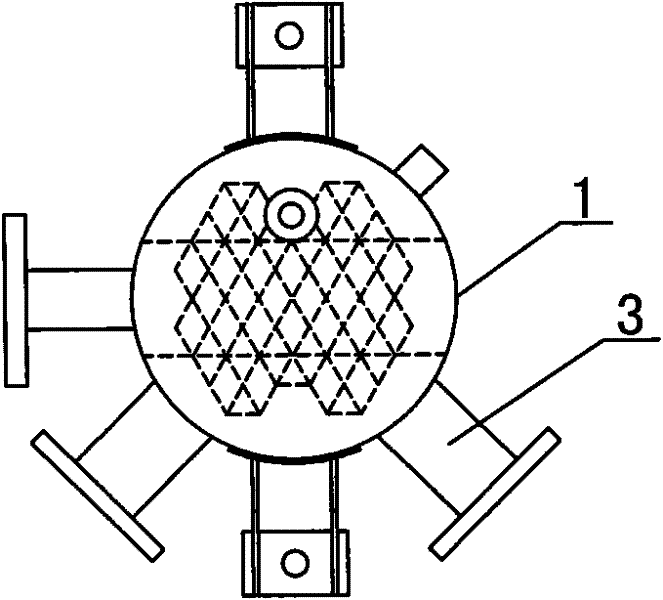

Shunt device of heater

InactiveCN102127850AReduce stress differentialSmall color differenceTextile treatment machine arrangementsShunt DeviceEngineering

The invention relates to a shunt device of a heater, comprising a dispensing cavity. The dispensing cavity is internally provided with a single dispensing pipeline, a dyeing liquor inlet and a dyeing liquor outlet are respectively arranged at both end parts of the outer side of the dispensing cavity, a condensate water outlet is arranged at the outer side of the cavity at the dyeing liquor inlet part, and a steam inlet is arranged at the outer side of the cavity at the dyeing liquor outlet part. The invention has the advantages that a traditional method of shunting dyeing liquor in a pipeline is improved into a method of directly and gradually unifying dyeing liquor to various nozzle systems by a channel through a single pipeline according to a structural principle of uniformly distributing channel air-liquid shunt pressure so as to reduce the pressure difference of various nozzles, further reach the uniform effect and reduce fabric chromatism.

Owner:WUXI HUIZE GENERAL MACHINERY

A performance test device for food refrigerators with parallel air supply

ActiveCN105021415BStable speedStable temperatureStructural/machines measurementWorking environmentAir treatment

The invention discloses a device of a parallel air supply type for testing the performance of a foodstuff refrigerator, and the device comprises a fence structure, a variable cross-section air supply static pressure space, a testing environment space, a variable cross-section air-turn static pressure space, an air processing apparatus, and an air supply header pipe disposed at the upper part of the fence structure. A non-uniform air supply pore plate and a non-uniform air return pore plate, which are arranged vertically, enable the lower space of the air supply header pipe to be sequentially divided into the variable cross-section air supply static pressure space, the testing environment space and the variable cross-section air-turn static pressure space in the direction of an air flow. The air processing apparatus is disposed at an outer side of the variable cross-section air-turn static pressure space. The device improves air distribution through parallel air supply, can guarantee that the air flow and temperature and humidity in in the testing space during testing to be uniform and stable, truly simulates the normal working environment of the foodstuff refrigerator, guarantees that the temperature and humidity and wind speed in the testing space meet the requirements of the JB / T 7244-1994 foodstuff refrigerator series standard.

Owner:江苏北洋冷链设备科技有限公司

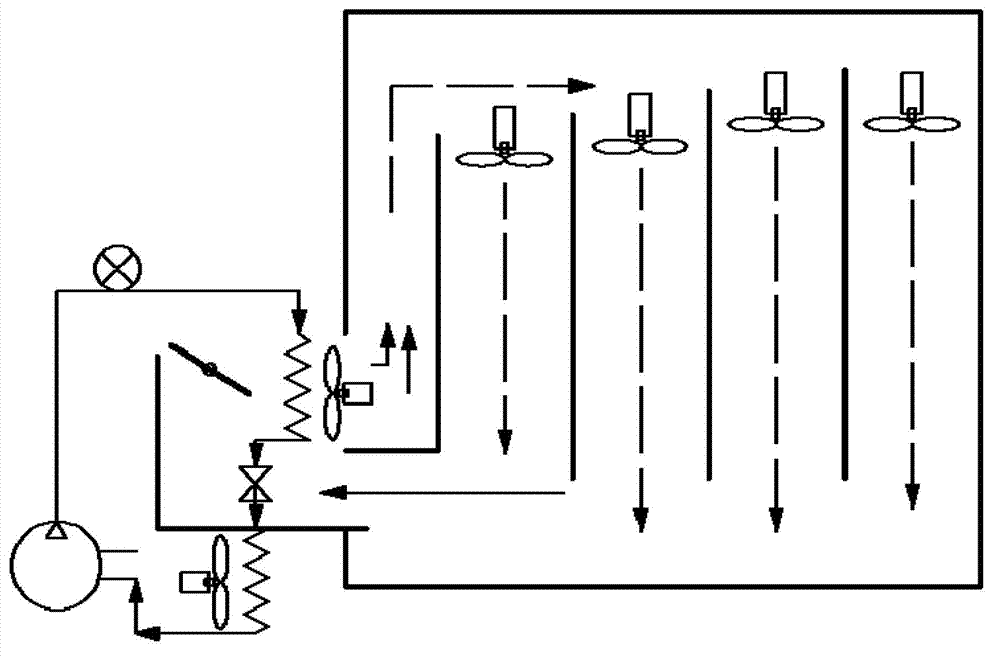

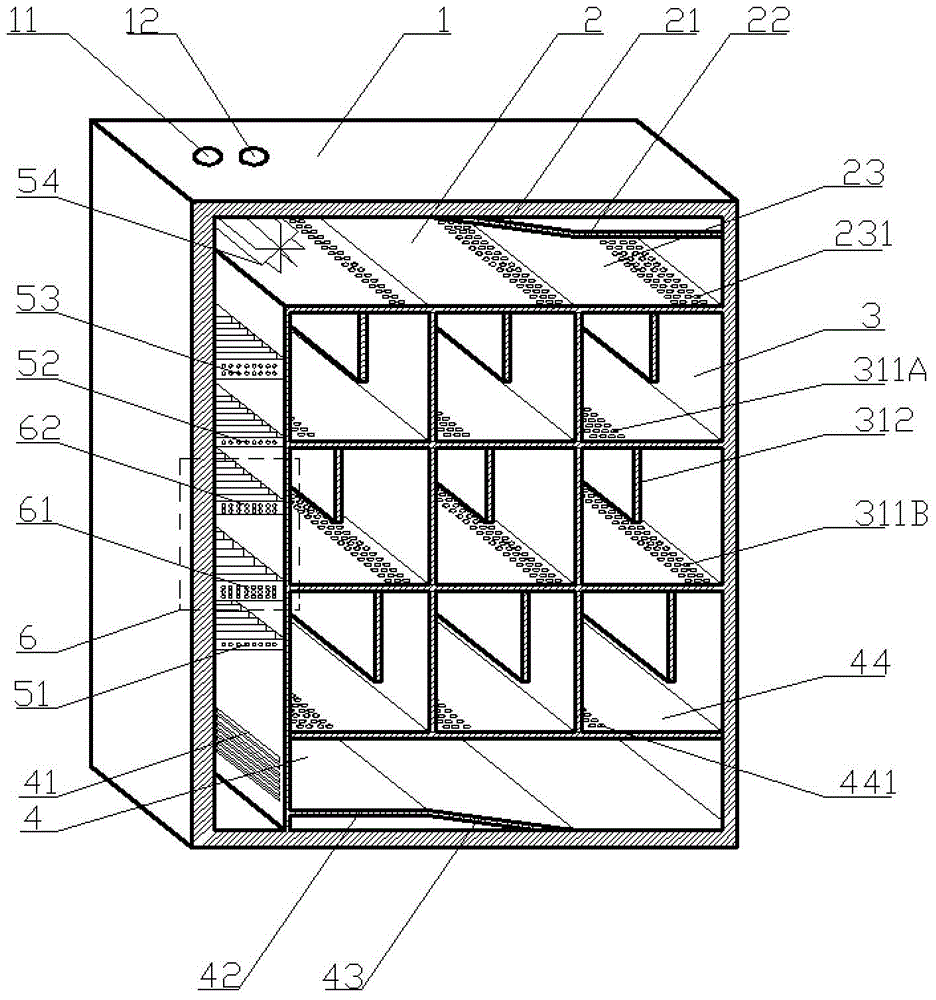

A vertical air supply type heat pump constant temperature equipment

ActiveCN105043080BReduce energy consumptionKeep dryHeat pumpsDrying gas arrangementsAir treatmentEngineering

The invention discloses vertical ventilation type heat pump thermostatic equipment. The equipment comprises a building envelope, a variable cross-section air supply static pressure space, drying areas, a variable cross-section air return static pressure space and an air treatment device. The lower portion of the variable cross-section air supply static pressure space is divided into three layers of drying areas in the airflow direction by an air supply non-uniform pore plate and an air return non-uniform pore plate which are horizontally arranged. The air treatment device is arranged on the outer side of the variable cross-section air return static pressure space. A group of air supply holes is arranged on the upper portion of the interior of each drying room on the top layer of each drying area, and air return holes are arranged below the drying room on the bottommost layer of each drying area. According to the equipment, dry air distribution is improved by means of vertical ventilation of a dry surface, uniformity and stability of airflow on the dry surface are guaranteed, drying efficiency is improved, and energy consumption is reduced.

Owner:NANJING NORMAL UNIVERSITY +1

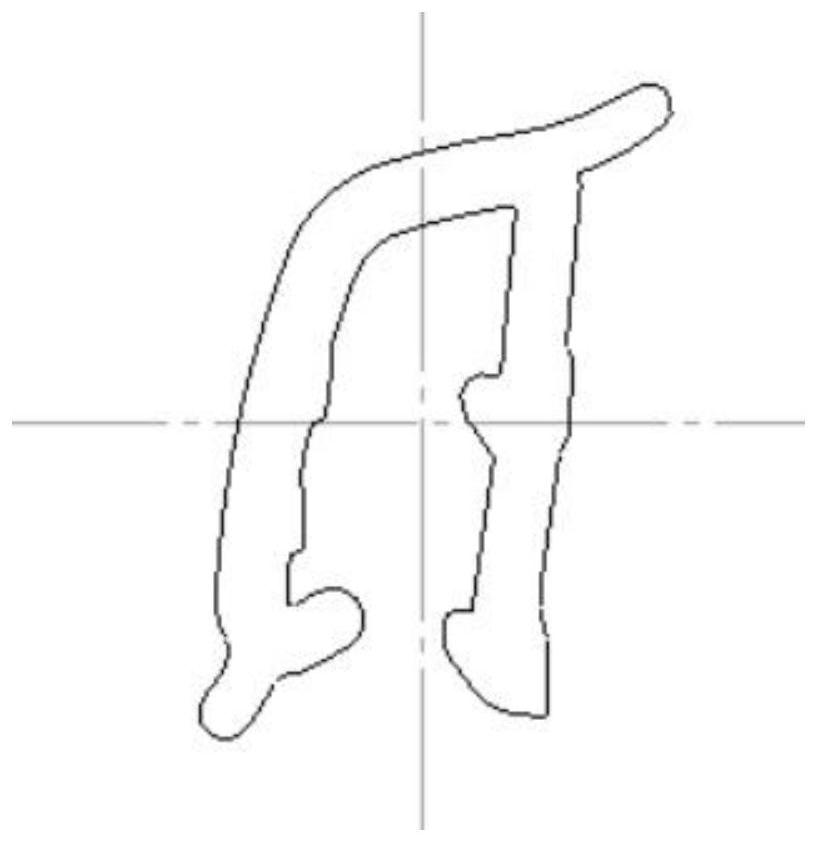

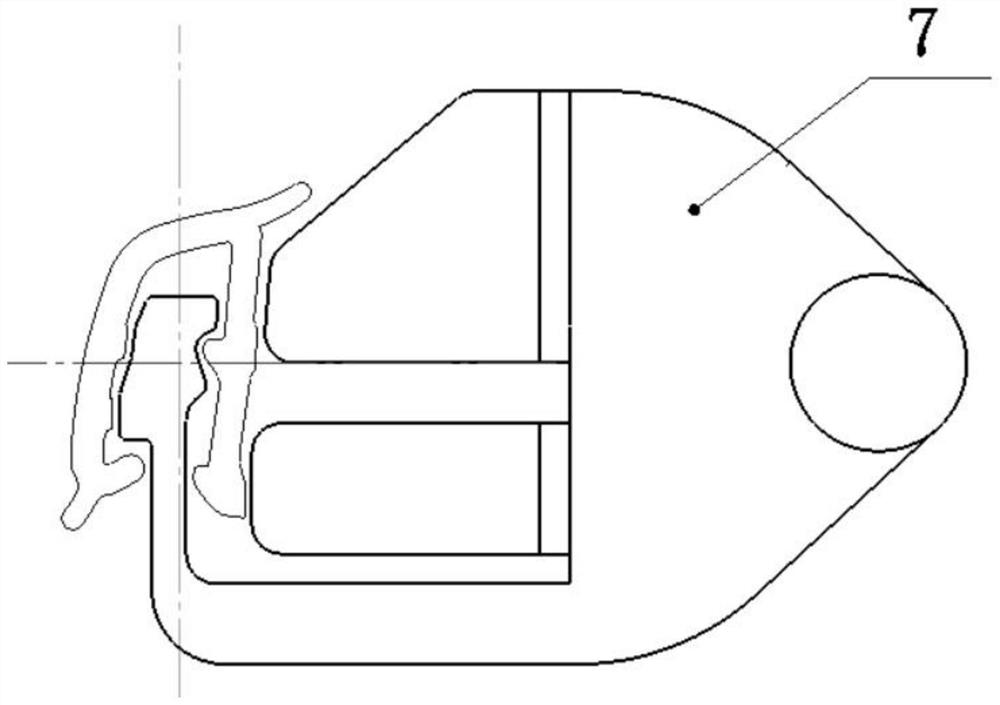

TPV clamping strip extrusion die

PendingCN112677446AControl Length DimensionsIncrease die inlet back pressureEngineeringMechanical engineering

The invention discloses a TPV clamping strip extrusion die which comprises a first mouth-shaped plate, a second mouth-shaped plate, a third mouth-shaped plate, a splitter plate and a fixing plate which are sequentially overlapped and fixed together, cavities which communicate with one another are formed in the first mouth-shaped plate, the second mouth-shaped plate and the third mouth-shaped plate, an auxiliary runner is arranged on one side of the cavity of the second mouth-shaped plate; a melt pool communicating with the first mouth-shaped plate is formed in the splitter plate, a framework positioning core is fixedly connected to the fixing plate, a guide hole is formed in the center of the framework positioning core, and main runners are symmetrically formed in the two sides of the framework positioning core. Multi-plate mouth-shaped matching is adopted, two feeding ports and one feeding port are adopted to control feeding of the appearance part of the product, each section of cavity is gradually decreased, the back pressure of each mouth-shaped inlet is increased, and roughness, lines and melt cracking of the appearance surface of the product are reduced; and the other feeding port controls feeding of the lip part, and the length of the lip of the product is controlled by independently adjusting the feeding amount of the lip part.

Owner:贵州红阳密封件有限责任公司

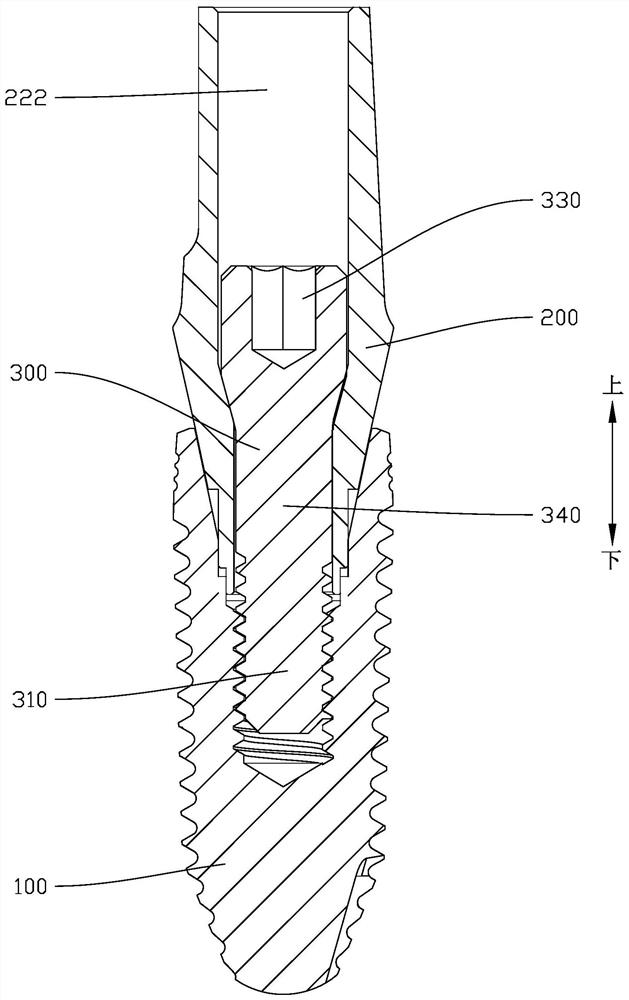

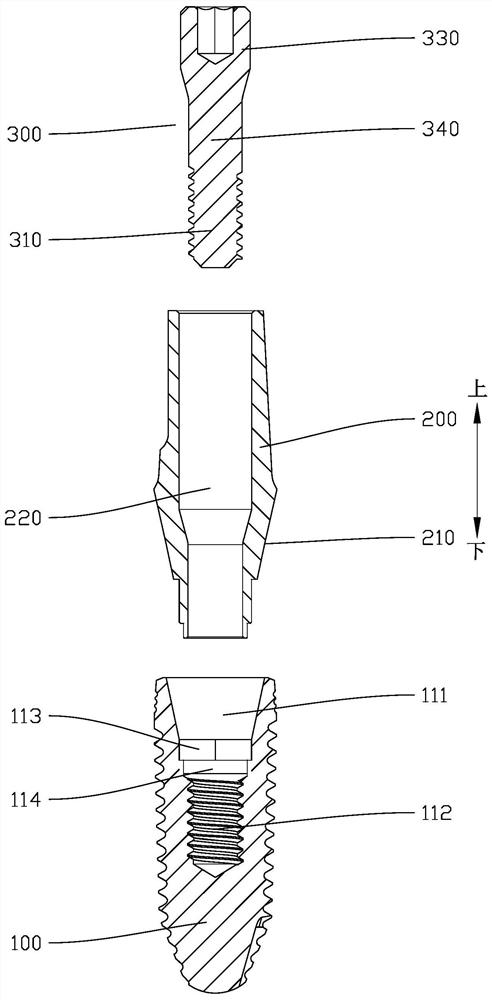

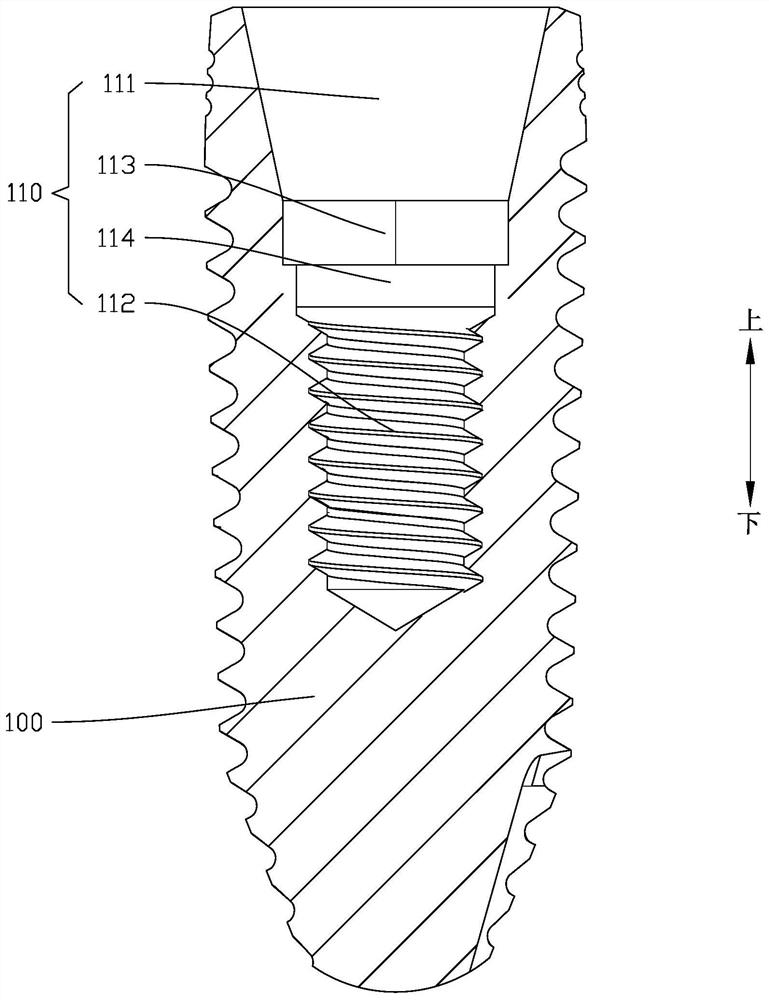

Double-sided fusion connected dental implant assembly

The invention discloses a double-sided fusion connected dental implant assembly, which comprises: an implant, wherein the top of implant is provided with a mounting hole, the inner wall of the top end of the mounting hole is provided with a first inner conical surface, and the implant is provided with a threaded hole; a base table, wherein a first outer conical surface is arranged on the outer wall of the base table, the first outer conical surface is attached to the first inner conical surface, an assembly hole is formed in the base table, a second inner conical surface is arranged on the inner wall of the assembly hole, and the conical angle of the second inner conical surface is equal to that of the first inner conical surface; and a central screw, wherein a screw rod is arranged at the bottom end of the central screw, the screw rod is connected with the threaded hole in a matched mode, a second outer conical surface is arranged on the outer wall of the central screw, and the second outer conical surface is attached to the second inner conical surface. According to the double-sided fusion connected dental implant assembly, cold pressure welding is ensured to be formed between the second outer conical surface and the second inner conical surface, so that double-sided fusion connection is formed among the implant, the abutment and the central screw, and the sealing performance of the dental implant assembly is favorably improved. The dental implant assembly can be applied to tooth implantation.

Owner:广东中科安齿生物科技有限公司

Local deformation improvement method and battery of high energy density flexible packaging ion battery

ActiveCN111463497BIncreasing the thicknessIncrease pressureFinal product manufactureSecondary cellsHigh energyEngineering

The invention provides a method for improving local deformation of a high-energy-density soft-packed ion battery and the battery, comprising: setting protective glue parameters and pasting protective glue on positive and negative pole pieces according to the protective glue parameters; using the positive pole piece pasted with protective glue Prepare winding cores with negative electrode sheets, and prepare the winding cores into batteries according to the battery preparation process; use a high-temperature pressurized forming cabinet to perform a formation operation on the batteries, and collect the batteries during the formation operations The thickness of multiple positions, according to the thickness of multiple positions of the battery, adjust the post-forming surface pressure of the battery; calculate the free electrolyte coefficient of the formed battery and set the vacuum according to the free electrolyte coefficient Time, according to the vacuuming time, vacuumize the battery cells that have been formed, and use the vacuumized battery cells to prepare lithium-ion batteries. The invention can obviously reduce the local deformation of the battery and enhance the service performance of the battery.

Owner:山东聚信新能源科技有限公司

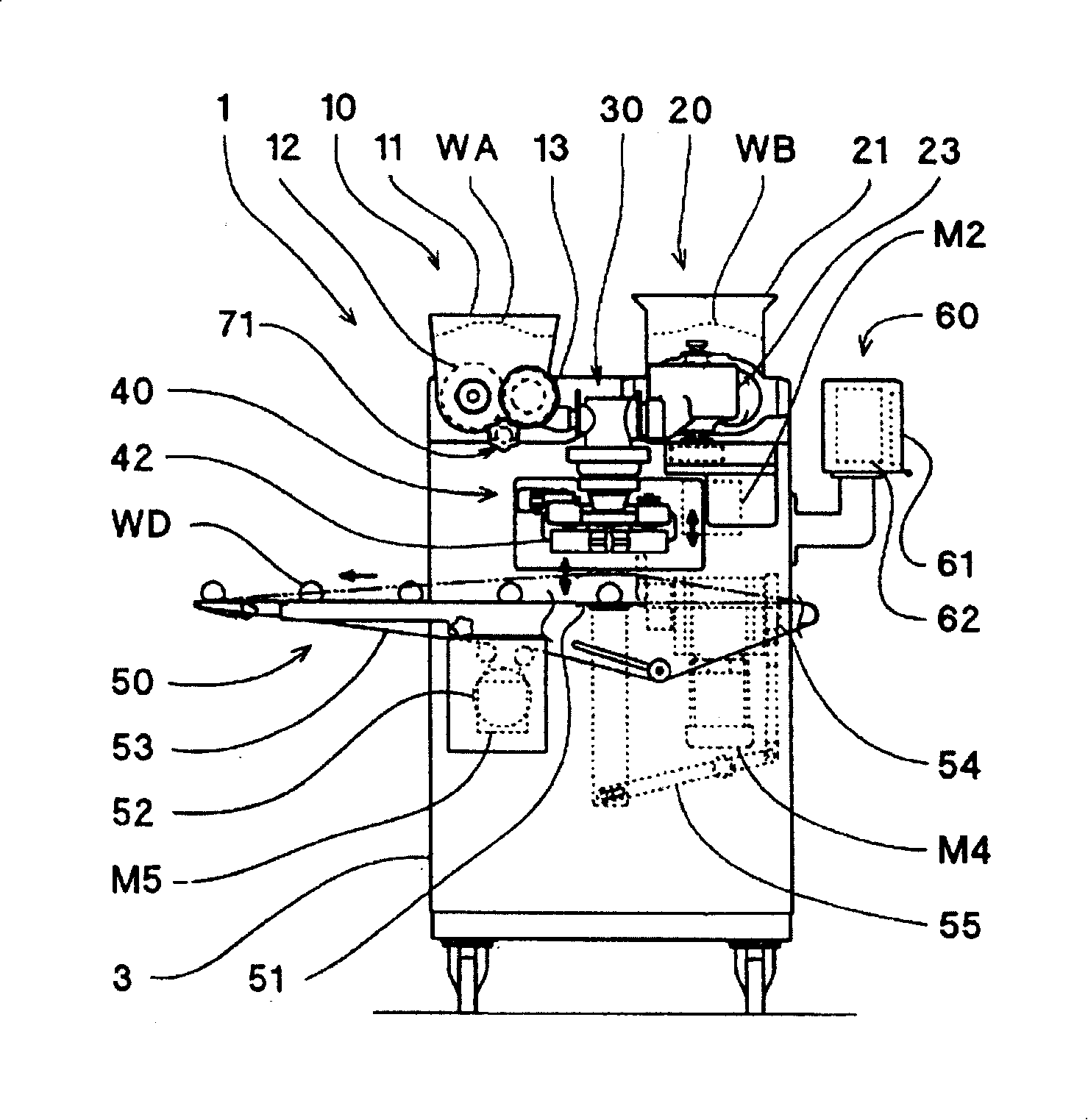

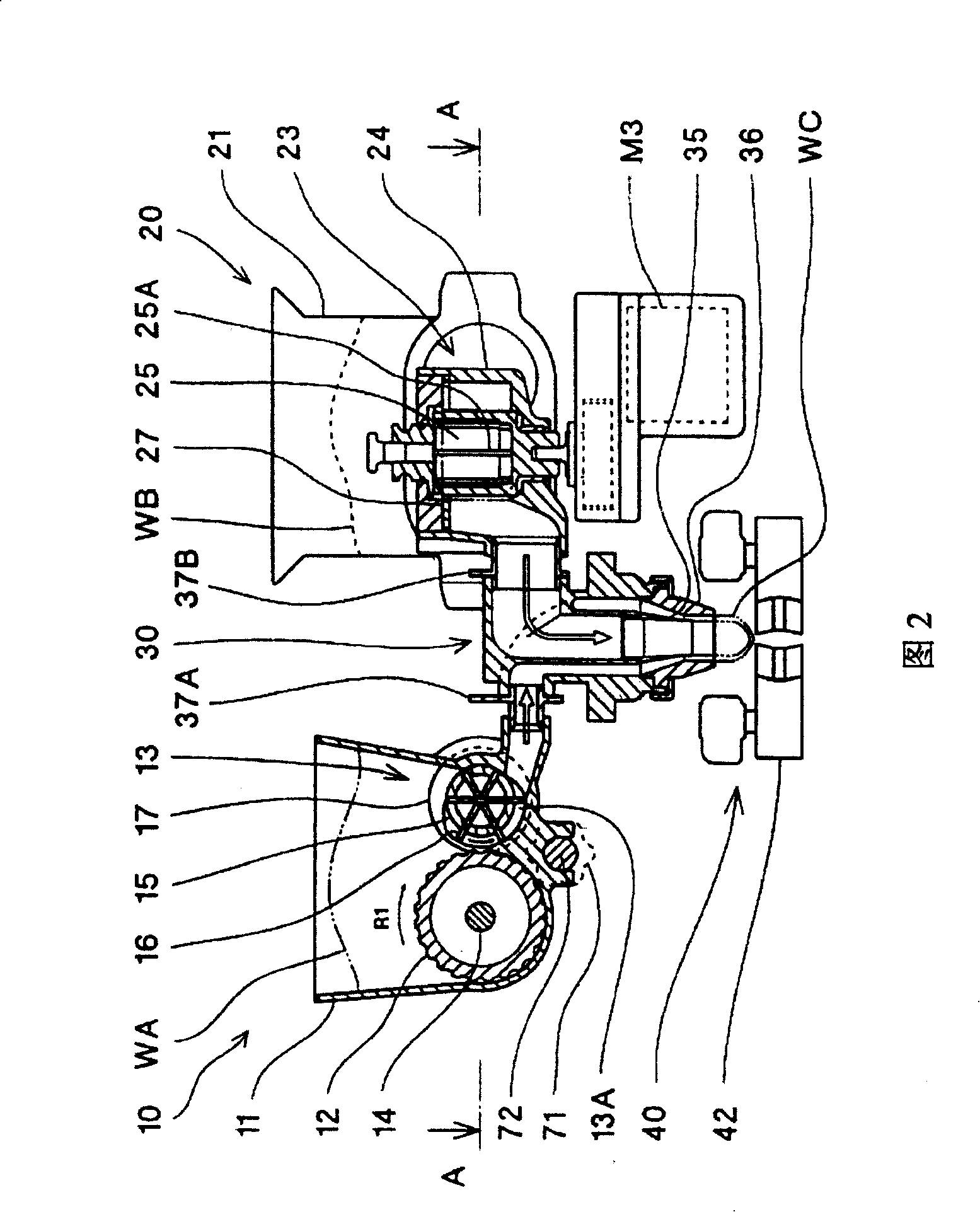

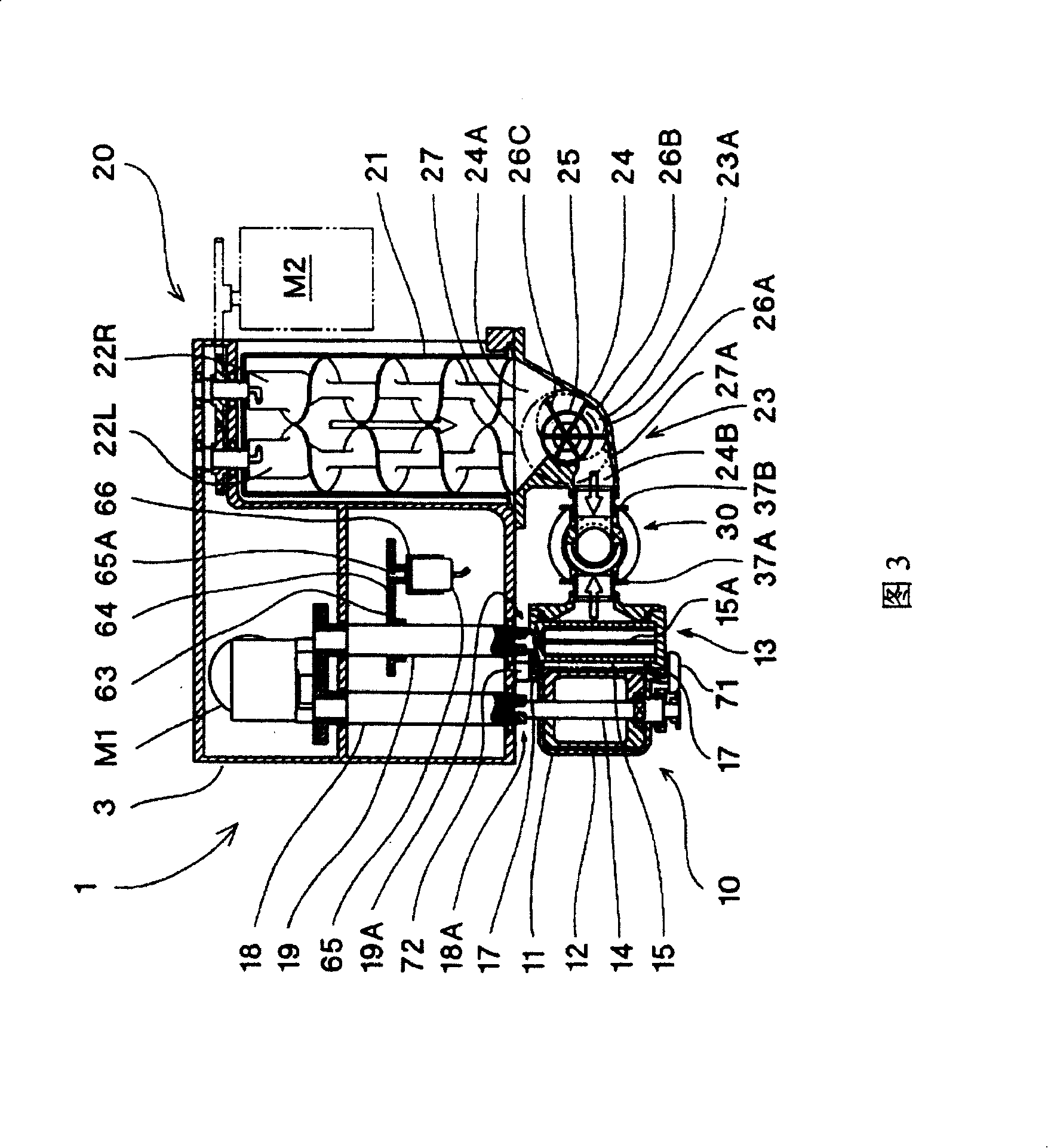

Food material supply method and device

ActiveCN100409773CPressure blockSmall weight differenceConfectionerySweetmeatsEngineeringFood material

The present invention provides a means for feeding a food material, which can reduce change of a pressure added to the food material in an exit side passage, when the food material is continuously feed into the exit side passage with a vane pump as a means for feeding the food material such as the dough or bean jam. In addition, the invention relates to a device for extruding bar-like food dough and a device for packing bean jam, the device for packing bean jam uses the means for feeding a food material.

Owner:RHEON AUTOMATIC MASCH CO LTD

A bottom-supply and top-return vertical air supply type heat pump constant temperature equipment

ActiveCN104997139BReduce energy consumptionOptimized airflow organizationFood processingFood treatmentAir treatmentThermostat

Owner:NANJING NORMAL UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com