A performance test device for a food refrigerator

A technology for testing devices and refrigerators, which is applied in measuring devices, testing of machines/structural components, instruments, etc. It can solve problems such as air supply temperature and humidity, uneven air distribution, turbulent air flow, small space and area, etc., to achieve environmental protection Uniform and stable temperature and humidity, increase the output range, and improve the effect of airflow organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

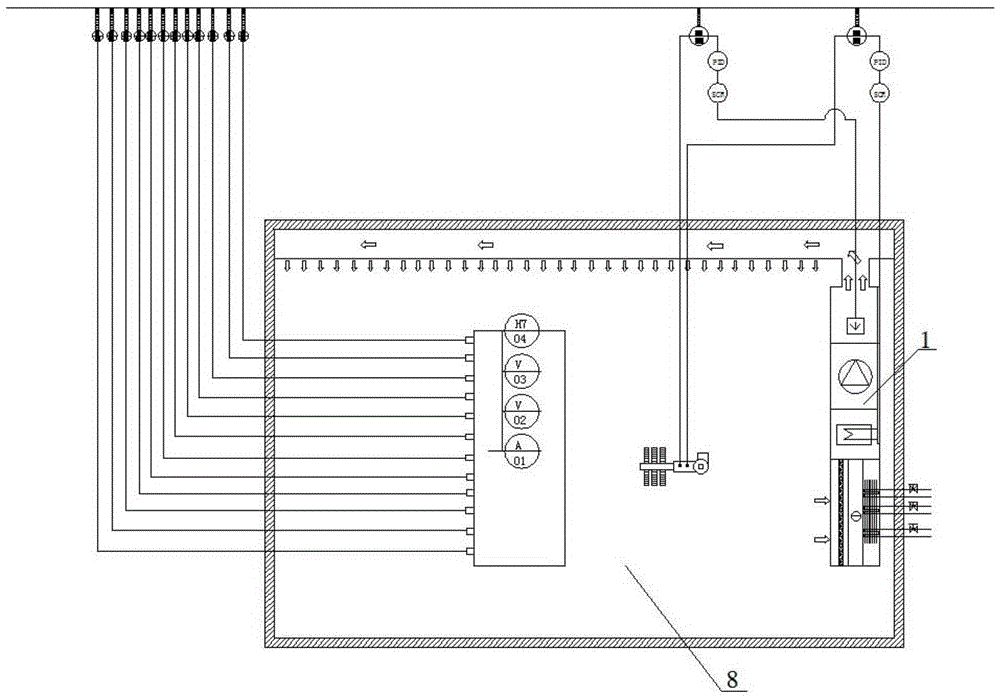

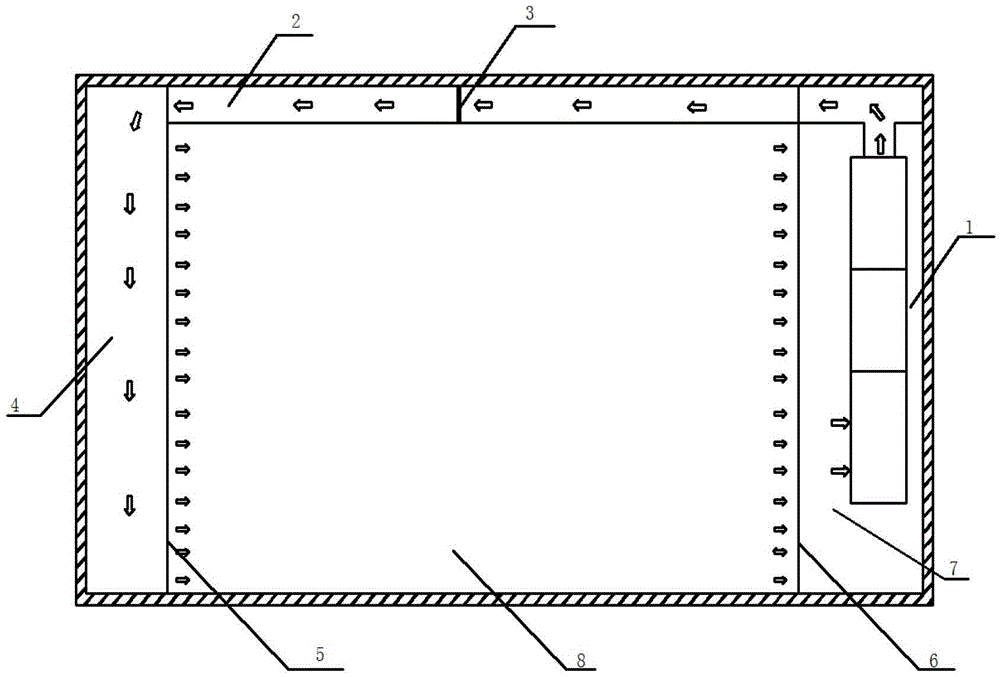

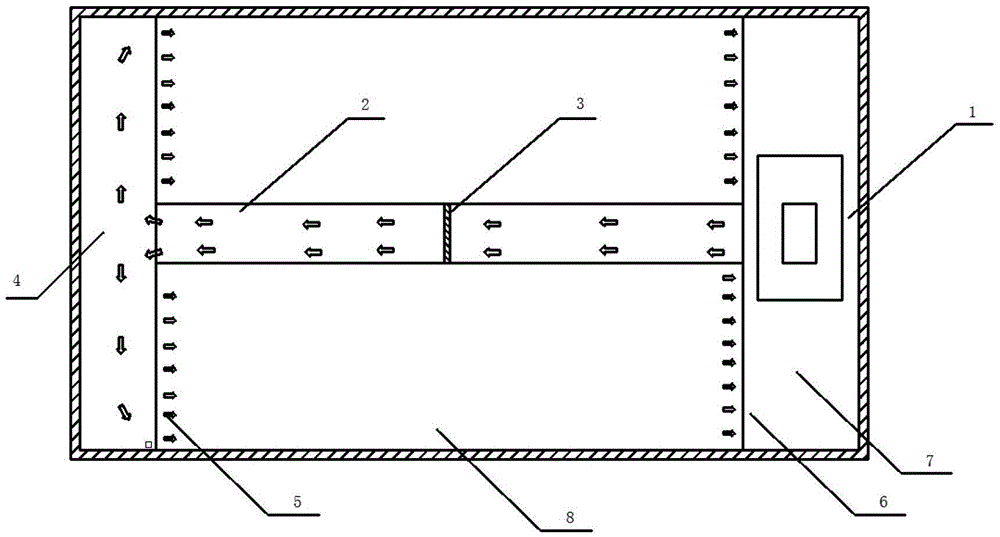

[0036] Such as image 3 , Figure 4 As shown, the food freezer performance testing device of the present invention includes a box body, a box top cover, an air handling unit 1, an air supply main pipe 2, an air mixing device 3, an air supply orifice 5 and a return air that are arranged in parallel in the box body. The orifice 6, the air supply orifice 5 and the return air orifice 6 divide the box into three areas, which are the air supply static pressure space 4 and the return air static pressure space 7 on both sides, and the test environment room 8 in the middle The air handling unit 1 is located in the return air static pressure space 7, the air handling unit 1 communicates with the air supply static pressure space 4 through the air supply main pipe 2, and the air mixing device 3 is arranged in the air supply main pipe 2 pipelines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com