A performance test device for food refrigerators with parallel air supply

A test device and food technology, which is applied in the field of construction environment and equipment engineering, can solve the problems of air flow turbulence, large air circulation flow resistance, and unsatisfactory satisfaction, so as to improve airflow organization, temperature and humidity, and reduce pressure differences , the effect of reducing the inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

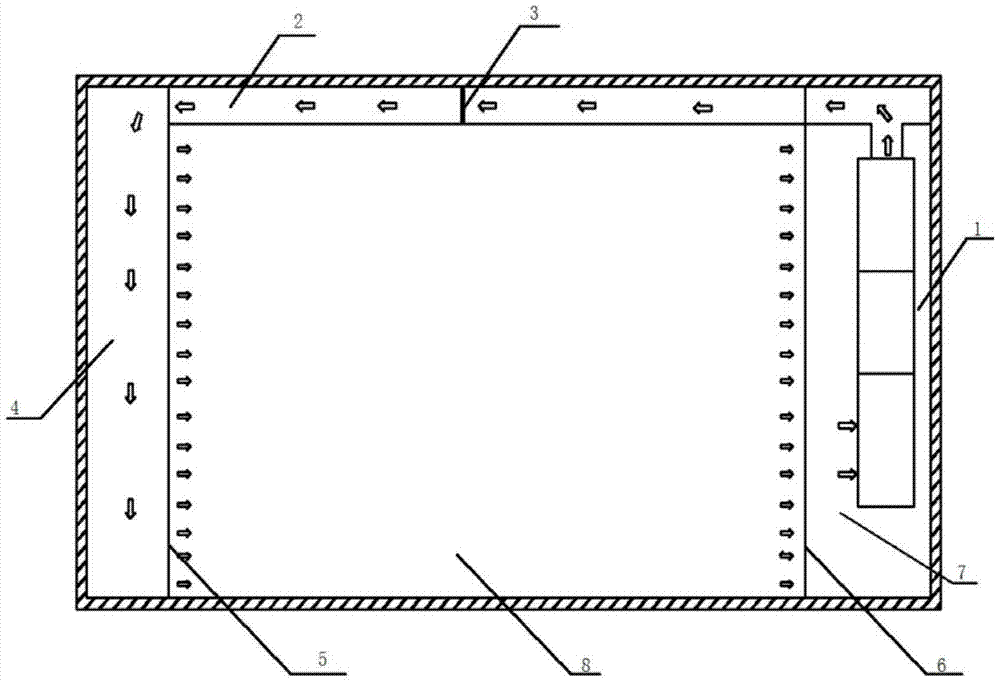

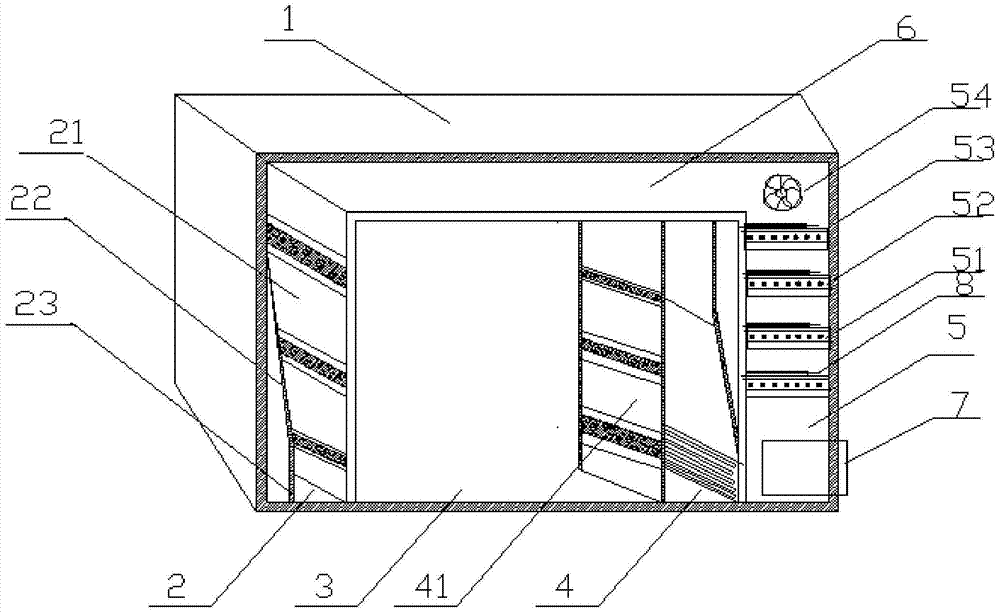

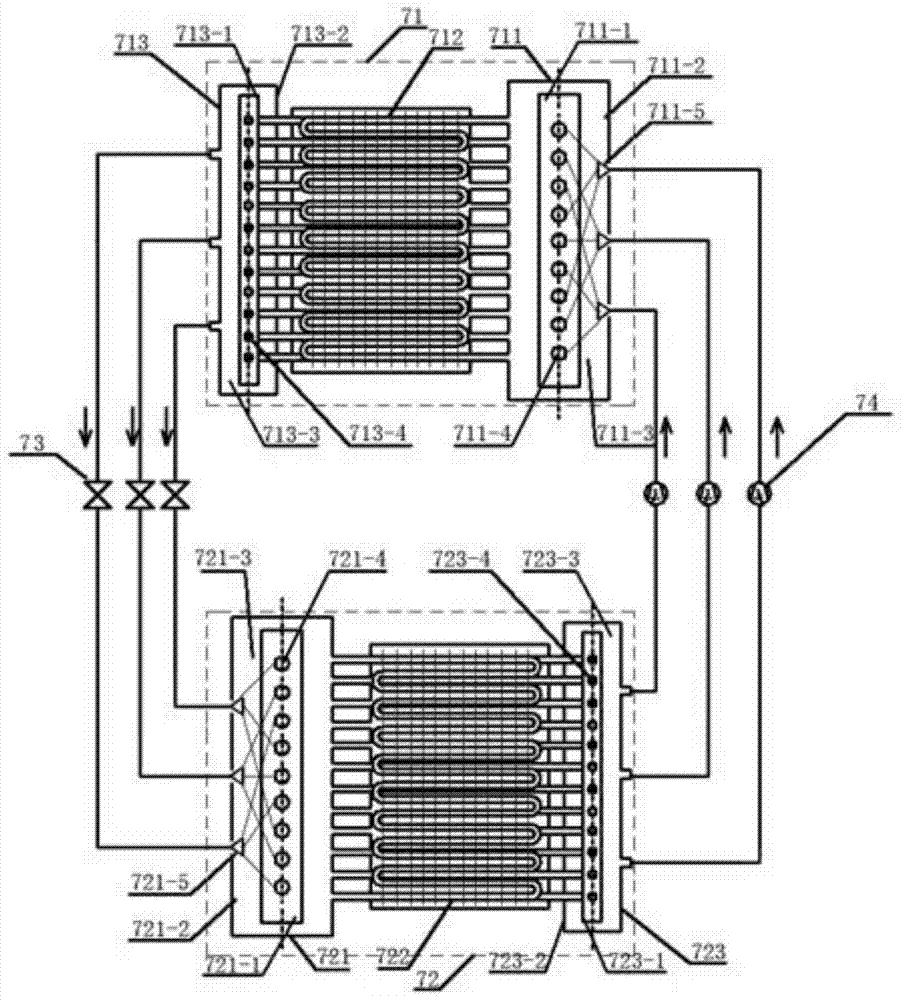

[0036] The parallel air supply type food refrigeration performance test device of the present invention includes an enclosure structure 1, a variable section air supply static pressure space 2, a test environment room 3, a variable section return air static pressure space 4, an air treatment device 5 and an air supply main pipe 6. The air supply main pipe 6 is set on the top of the enclosure structure 1, and the lower structure is divided into three parts by the air supply non-uniform orifice plate 21 and the return air non-uniform orifice plate 41. Along the air flow direction, there are variable cross-section air supply static pressure spaces 2. Test The environment room 3 and variable cross-section return air static pressure space 4, the variable cross-section air supply static pressure space 2 and the test environment room 3 are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com