A bottom-supply and top-return vertical air supply type heat pump constant temperature equipment

A technology of constant temperature equipment and heat pump, which is applied in the field of construction environment and equipment engineering, can solve the problems that the baking workshop cannot fully achieve uniform and stable air flow organization, affects the wind speed and air volume in the drying area, and has a large influence on the airflow direction. The effect of improving energy utilization, shortening the drying process, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

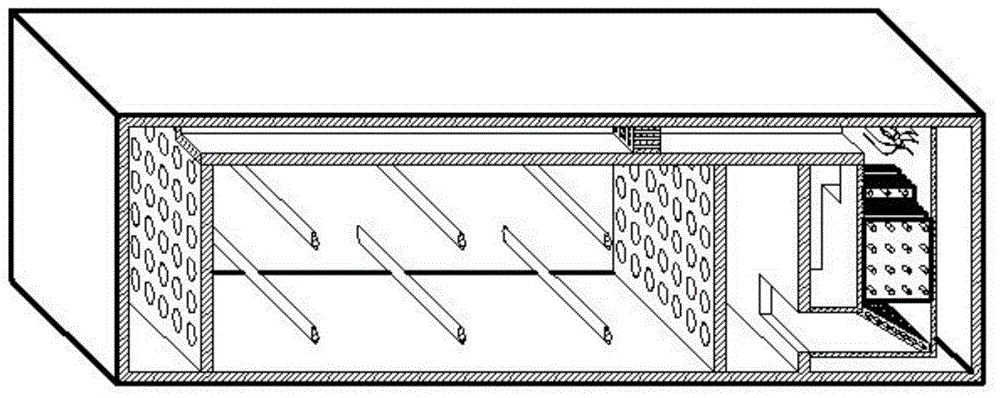

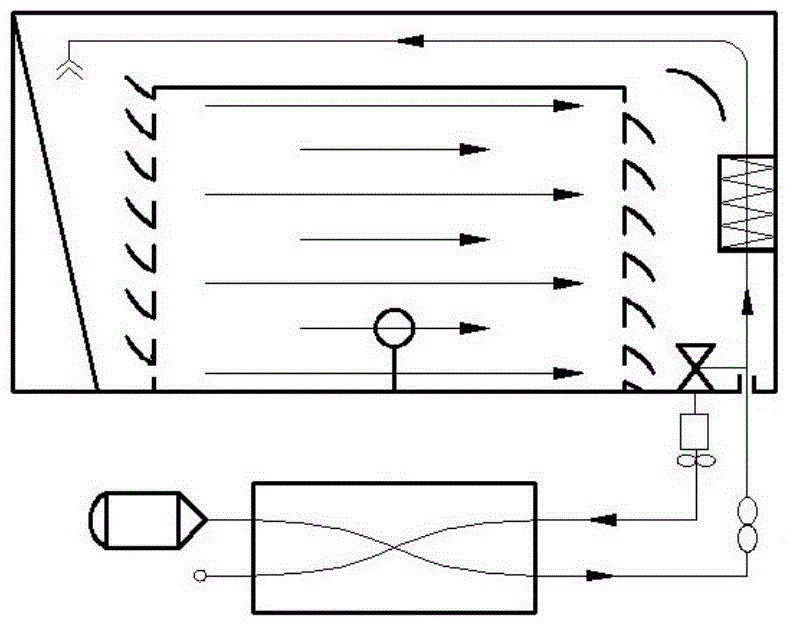

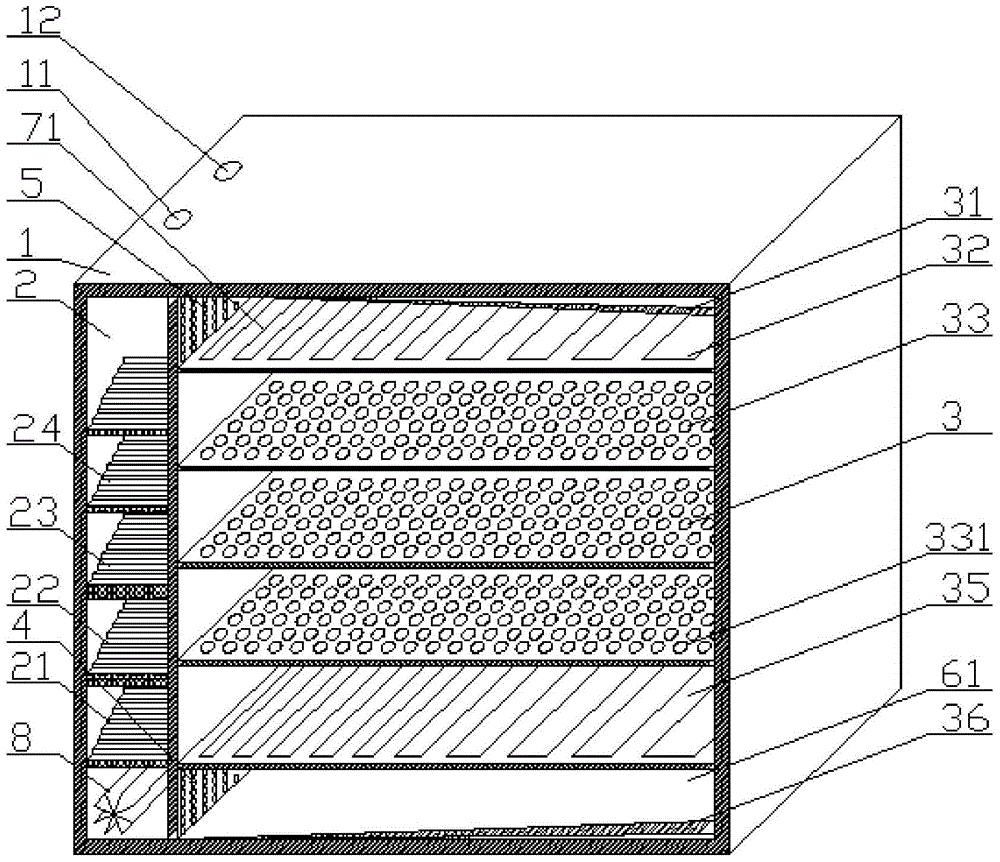

[0034] The bottom-feeding and top-returning vertical ventilation type heat pump constant temperature equipment of the present invention includes an enclosure structure 1, an air treatment device 2, a drying area 3, a return air orifice 4 and a supply orifice 5, a variable cross-section return air static pressure space and Variable cross-section air supply static pressure space. The return air orifice 4 is arranged at the lower part of the enclosure structure 1, and the air supply orifice 5 is arranged at the upper part of the enclosure structure 1. The air treatment device is composed of 5 parts, from bottom to top are the fan 8, the electric heater 21, the solar heater 22, the evaporation and condensation circuit 23, and the adsorption device 24. The air processing device 2 communicates with the drying area 3 through the return air orifice 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com