Edible fungus dried air circulation treatment device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

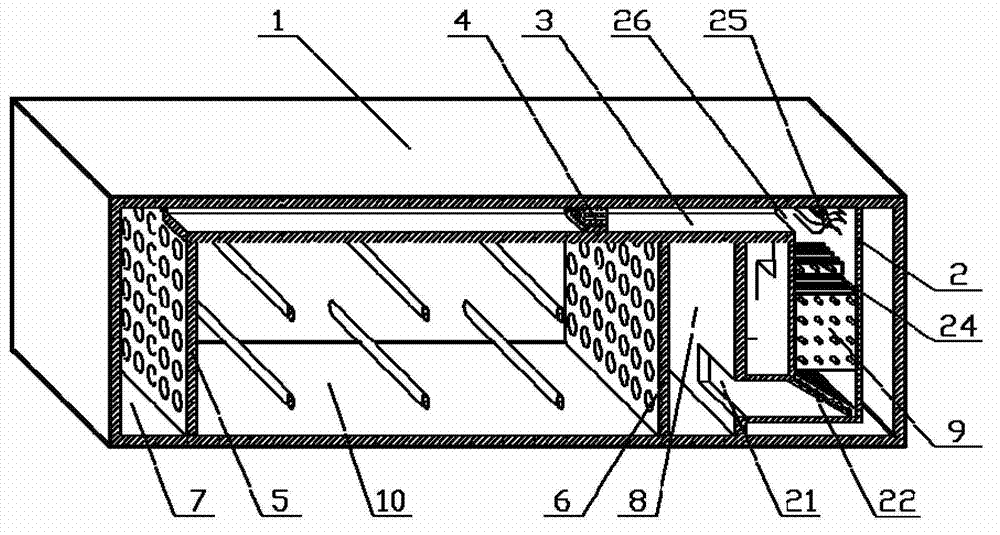

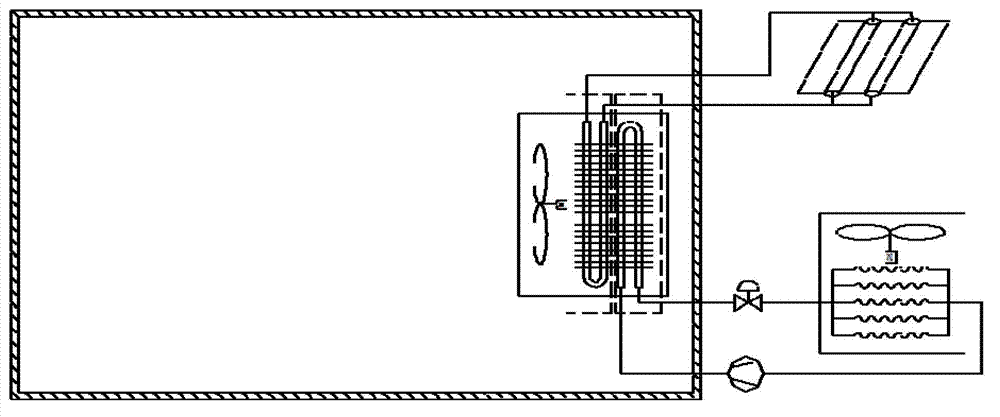

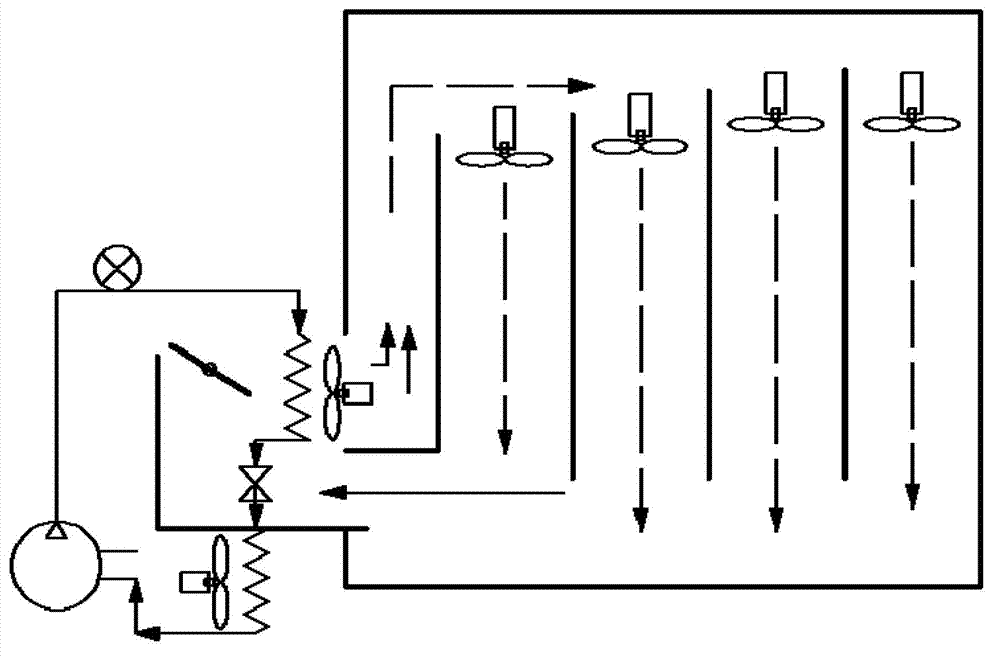

[0036] The edible mushroom drying air circulation processing device of the present invention comprises a baking room 1, an air handling unit 2, an air supply main pipe 3, an air mixing device 4, an air supply orifice 5 and a return air orifice arranged in parallel in the baking chamber 6. The air supply orifice 5 and the return air orifice 6 divide the baking chamber into three areas, which are the air supply static pressure space 7 and the return air static pressure space 8 on both sides, and the baking workshop 10 in the middle. The air handling unit 2 is located outside the return air static pressure space 8, the air handling unit 2 communicates with the air supply static pressure space 7 through the air supply main pipe 3, and the air mixing device 4 is arranged in the air supply main pipe 3 pipelines.

[0037] The air handling un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com