A middle air supply type edible mushroom circulation drying device

A technology of circulating drying and edible fungus, which is applied in the direction of drying gas arrangement, heating device, drying, etc., can solve the problems of large horizontal influence, affecting the wind speed and air volume in the drying area, and the air volume distributed by the air supply orifice plate, and achieve the speed field and The temperature field distribution is stable, the heat utilization rate is improved, and the effect of increasing the drying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

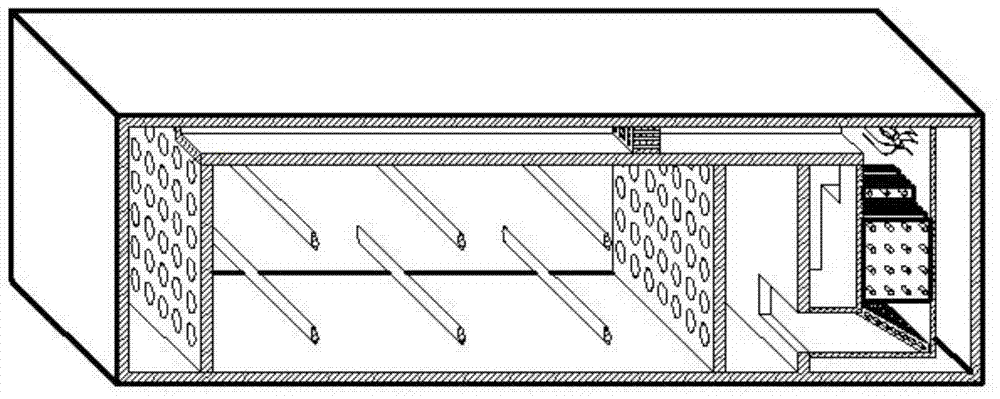

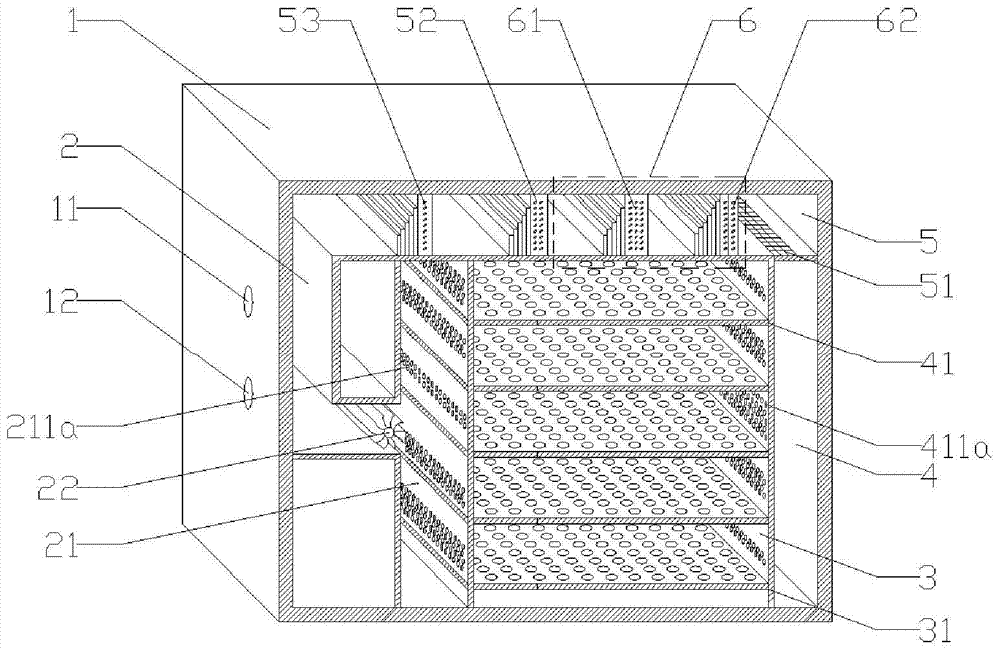

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

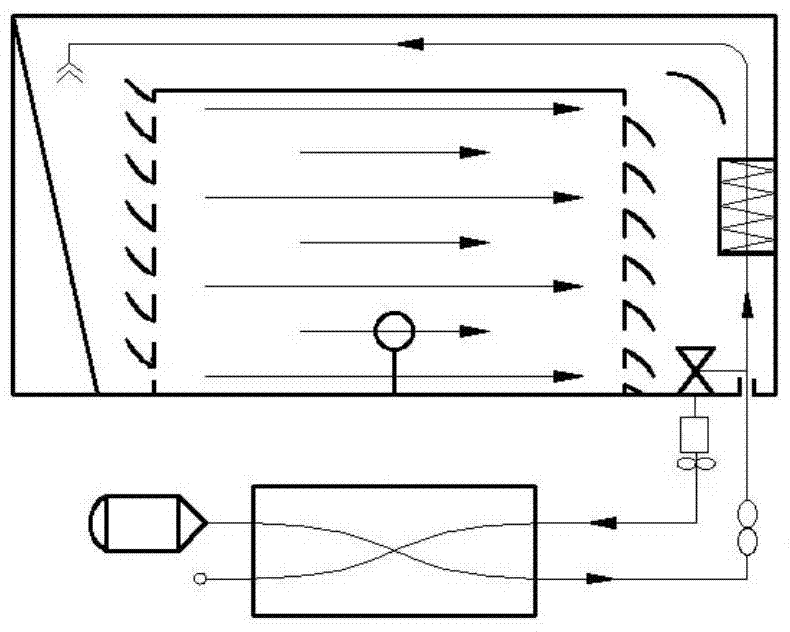

[0031] The intermediate circulation air supply type edible mushroom drying device of the present invention includes an enclosure structure 1 , an air supply main pipe 2 , a drying area 3 , a return air main pipe 4 , and an air treatment device 5 . A fresh air outlet 11 and an air exhaust outlet 12 are provided on the left outside of the enclosure structure 1 . The air supply main pipe 2 is arranged on the left side of the enclosure structure 1, and the lower structure is divided into three parts by the air supply non-uniform orifice plate 21 and the return air non-uniform orifice plate 41. Along the airflow direction, there are air supply main pipe 2, drying area 3 and The return air main pipe 4, the air supply main pipe 2 and the drying area 3 are divided by the air supply non-uniform orifice 21, the drying area 3 and the return air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com