Method for improving local deformation of high-energy-density flexible package ion battery and battery

A high energy density, ion battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of slow liquid absorption, deformation of lithium analysis position, white spots, etc., to reduce the pressure difference and solve the bottom angle deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

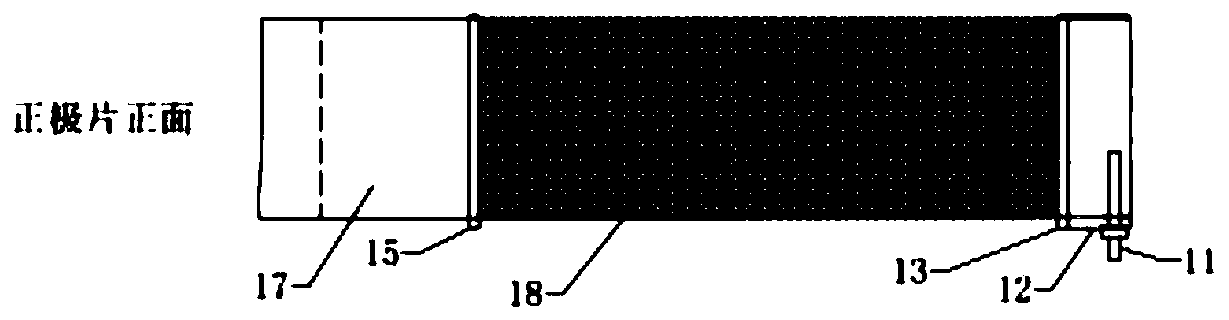

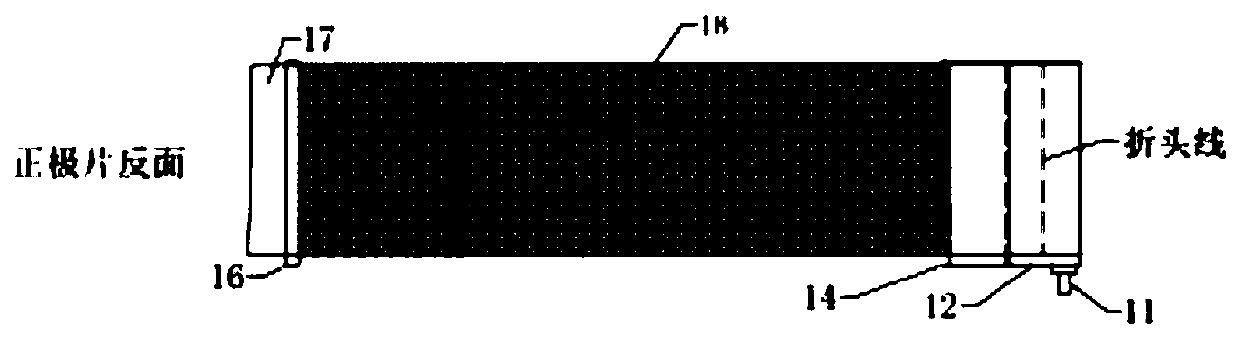

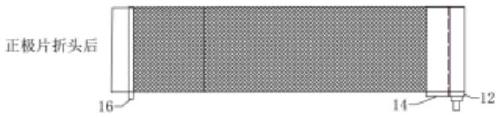

[0085] Please refer to Figure 1-3 The method for improving the local deformation of the high-energy-density soft-packaged ion battery provided in this embodiment adopts a different positive electrode sheet compared with the existing method.

[0086] A positive electrode piece, the positive electrode piece includes a positive electrode tab 11, a positive electrode tab protective glue 12, a positive electrode coating line 1 protective glue 13, a positive electrode coating line 2 protective glue 14, a positive electrode coating line 3 protective glue 15, Positive electrode coating line 4 protective glue 16, positive electrode strip 17, positive electrode material area 18.

[0087] For the positive pole piece, the size of the folded end of the positive electrode is 16 mm, the distance between the positive metal strip and the folded end line after folding is 5 mm, the width of the positive tab 11 is 6 mm, the width of the positive tab protector 12 is 18 mm, and the positive coatin...

Embodiment 2

[0089] Please refer to Figure 4-6 , This embodiment provides a method for improving local deformation of a high-energy-density soft-packaged ion battery. Compared with the existing battery preparation method, the method differs in that the following negative electrode sheet is used.

[0090] A negative pole piece, the negative pole piece comprises a negative pole lug 21 , a negative pole lug protective glue 22 , a negative pole balance tape 23 , a negative pole piece tape 24 , and a negative pole material area 25 .

[0091] For the negative electrode sheet, the size of the folded end of the negative electrode is 17mm, the distance between the positive metal strip and the folded end line after folding is 7mm, the width of the negative electrode lug 21 is 6mm, the width of the negative electrode lug protection glue 22 is 17mm, and the negative electrode balance glue 23 The width is 28mm.

Embodiment 3

[0093] Please refer to Figure 7-8 , using the positive electrode sheet and the negative electrode sheet obtained in Example 1 and Example 2, after adding a separator, the winding core 31 was prepared by winding.

[0094] The distance between the tabs of the winding core is 10mm, and the length of the winding core termination tape 32 is 89mm. The core, core top glue 33 has a width of 8mm and a length of 20mm

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com