Lamp shell, lamp with lamp shell and manufacturing method for lamp shell

A lamp housing and extension direction technology, applied in the field of lighting, can solve problems such as shadows, unevenness, and lighting effects on the lighting surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

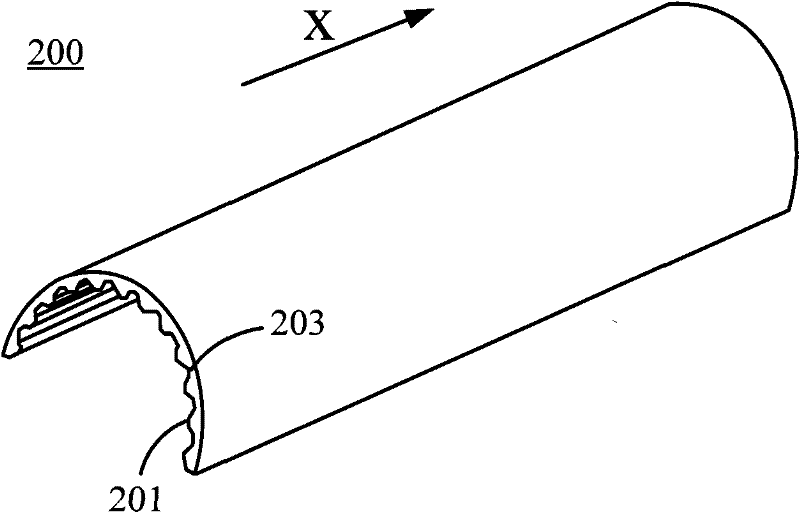

[0027] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings. In the drawings, the same or similar parts are denoted by the same or similar reference numerals. In order to avoid obscuring the gist of the present invention due to unnecessary details, only structures and components closely related to the solutions of the present invention are shown in the drawings, while other details that are not relevant are omitted.

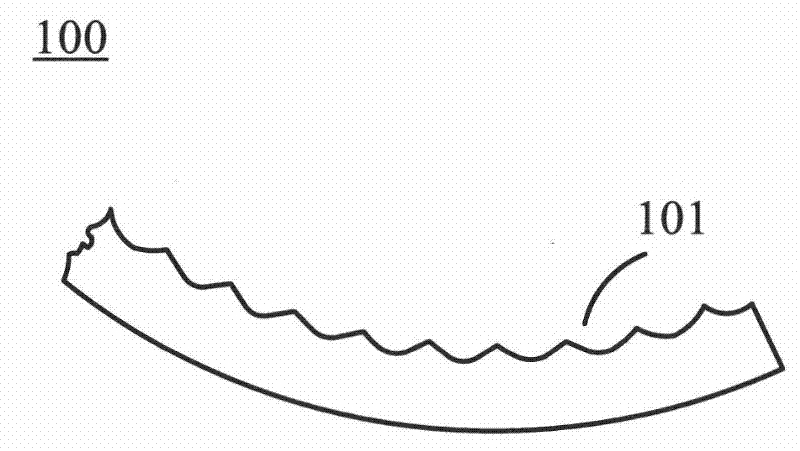

[0028] see Figure 1A and Figure 1B . Figure 1A is a cross-sectional view showing the microstructure on the lamp housing 100 in the prior art. Reference numeral 101 denotes a groove structure on the surface (inner surface) of the lamp housing 100 facing the light source. The plurality of grooves 101 form a discontinuous microstructure on the inner surface of the lamp housing 100 with a cross-sectional profile curve. Figure 1B is shown using Figure 1A The diagram of the lighting effect of the lam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com