Diffracted optical waveguide, manufacturing method, and method and device for improving uniformity of emergent light

A technology of uniformity and outgoing light, applied in the field of optical imaging, can solve the problems of no mass production feasibility, limited improvement effect, difficult design of gratings, etc., and achieve the effect of low price, improved uniformity of outgoing light, and uniform brightness of light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

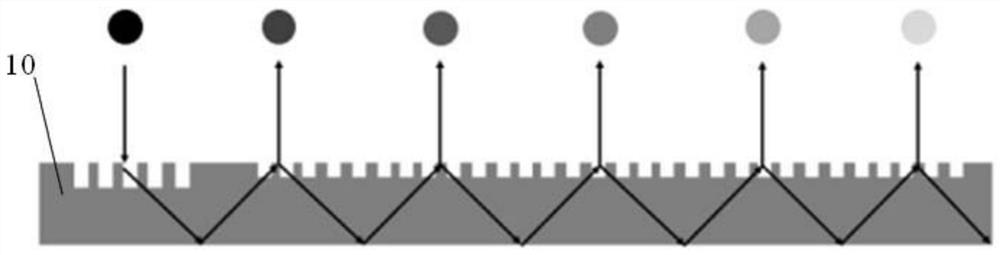

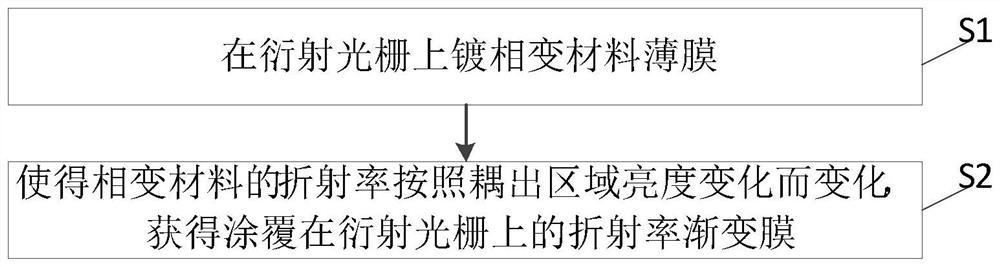

[0036] figure 2 is a schematic diagram of a diffractive optical waveguide that improves the uniformity of outgoing light according to the present invention, as figure 2 As shown, the diffractive optical waveguide 10 includes a diffraction grating 1 and a graded refractive index film 2 coated on the diffraction grating, and the uniformity of the brightness of the outcoupled light is improved by changing the refractive index of the graded refractive index film 2 in different outcoupling regions , preferably, the refractive index of the gradient index film becomes larger along the pupil expansion direction, the larger the refractive index of the gradient index film is, the greater the brightness of the outcoupled light, that is to say, the gradient index film at the front end of the pupil expansion direction The reduction of the refractive ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com