Systems and methods for producing oil and/or gas

A technology for oil recovery and oil enhancement, used in chemical instruments and methods, earthmoving, wellbore/well components, etc., to solve problems such as harmful effects on the environment, air pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

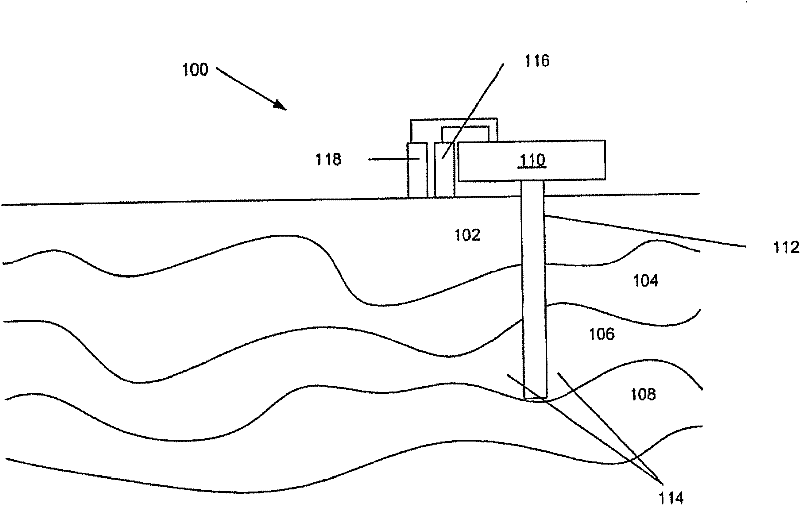

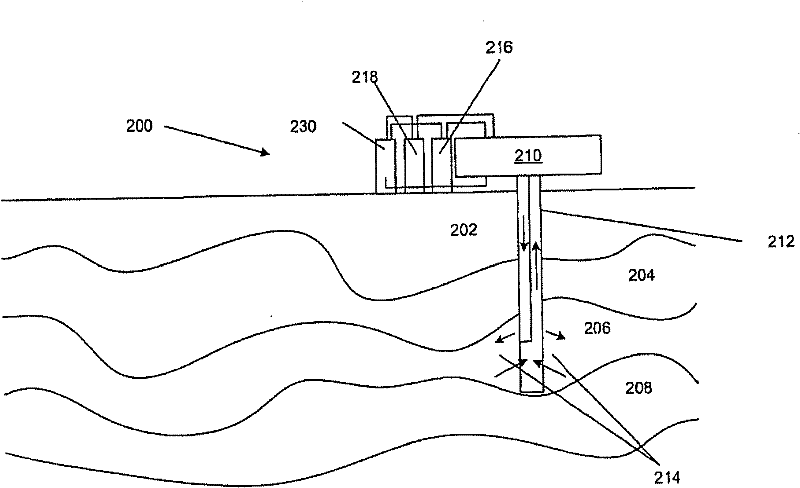

[0079] In some embodiments, the carbon disulfide derived salt may be dissolved in water and the resulting solution pumped into the formation 206 and / or 306 . The dissolved carbon disulfide formulation may decompose to produce carbon disulfide in the formation 206 and / or 306 .

[0080] In some embodiments of the invention, the gases and liquids produced by wells 212 and / or 312 may be separated using gravity separators or centrifugal separators or other methods known in the art. The gas portion may be sent to carbon disulfide formulation production facilities 230 and / or 330 .

[0081] In some embodiments of the invention, all components of system 200 and / or system 300 may be within about 10 km, such as about 5, 3 or 1 km, of each other.

[0082] In some embodiments, oil and / or gas produced by wells 212 and / or 312 may be sent to a refinery and / or processing facility. Oil and / or gas can be processed to produce commercial products such as transportation fuels such as gasoline and...

Embodiment

[0086] Table 1 gives the flammability properties of carbon disulfide, including flash point, autoignition temperature, and flammability limit in air at 25°C. Corresponding flammability data for other commonly used oilfield and chemical industry substances are also given. It can be seen that the distinguishing feature of carbon disulfide solvents is their very low autoignition temperature, or the minimum temperature at which they are capable of spontaneous ignition in the presence of air in the absence of an ignition source. A wide flammability limit makes this ignition more likely. Even highly flammable hydrocarbons (ie octane and decane) and hydrocarbon mixtures (ie diesel or LPG) have auto-ignition temperatures above 100°C, and narrower flammability limits. In fact, the low autoignition temperature puts carbon disulfide itself in the combustible class of substances, as there have also been reports of fires caused by contact of drifting carbon disulfide vapors with incandesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com