Full peripheral process unit for electric erosion machining valve bushes

A process device and electro-erosion processing technology, applied in electric processing equipment, accessories, metal processing equipment, etc., can solve the problems of large processing error, affecting processing quality, insufficient cooling, etc., to ensure shape and position accuracy and surface roughness. degree, the machine structure is simplified, and the cooling effect is sufficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

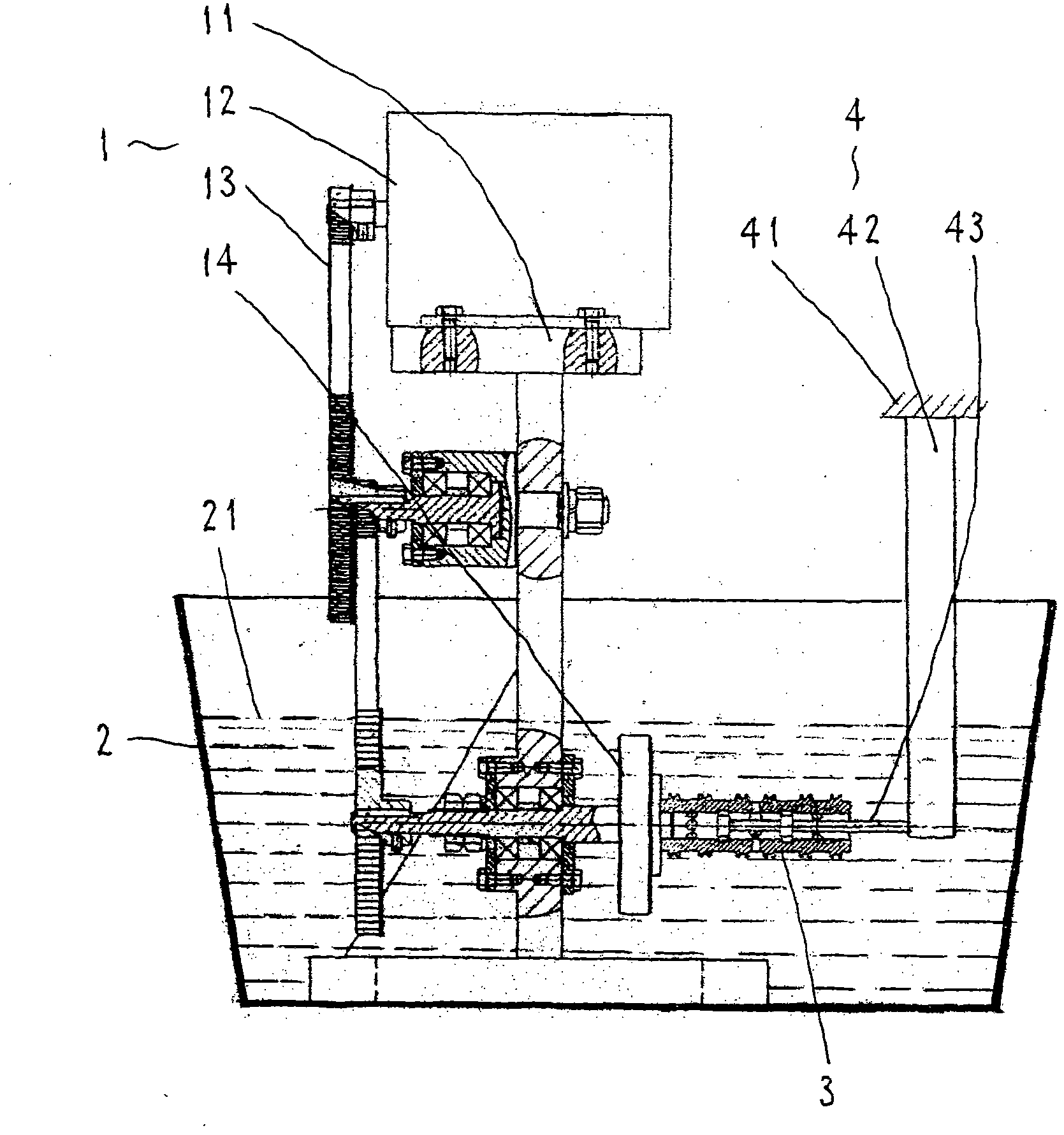

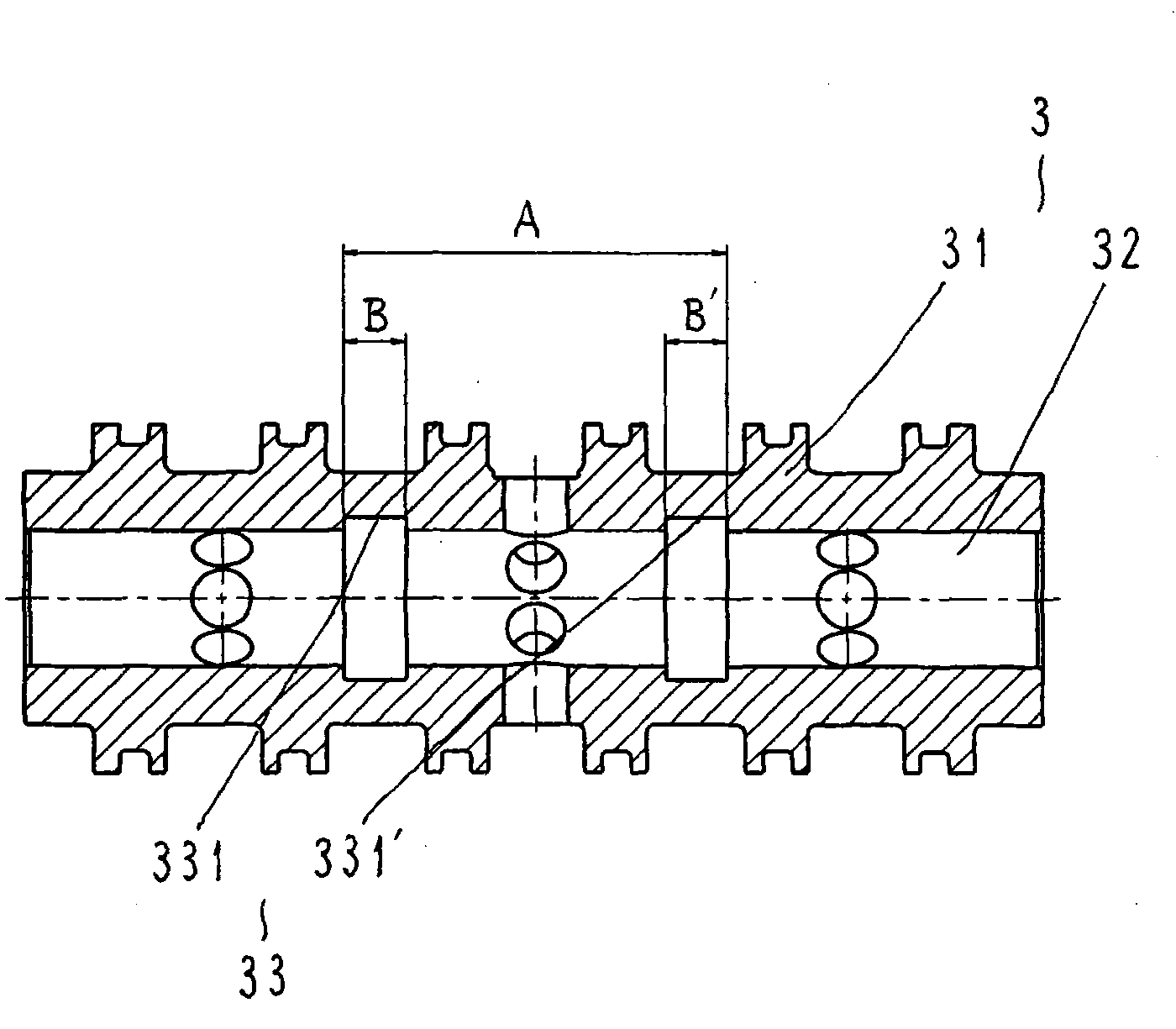

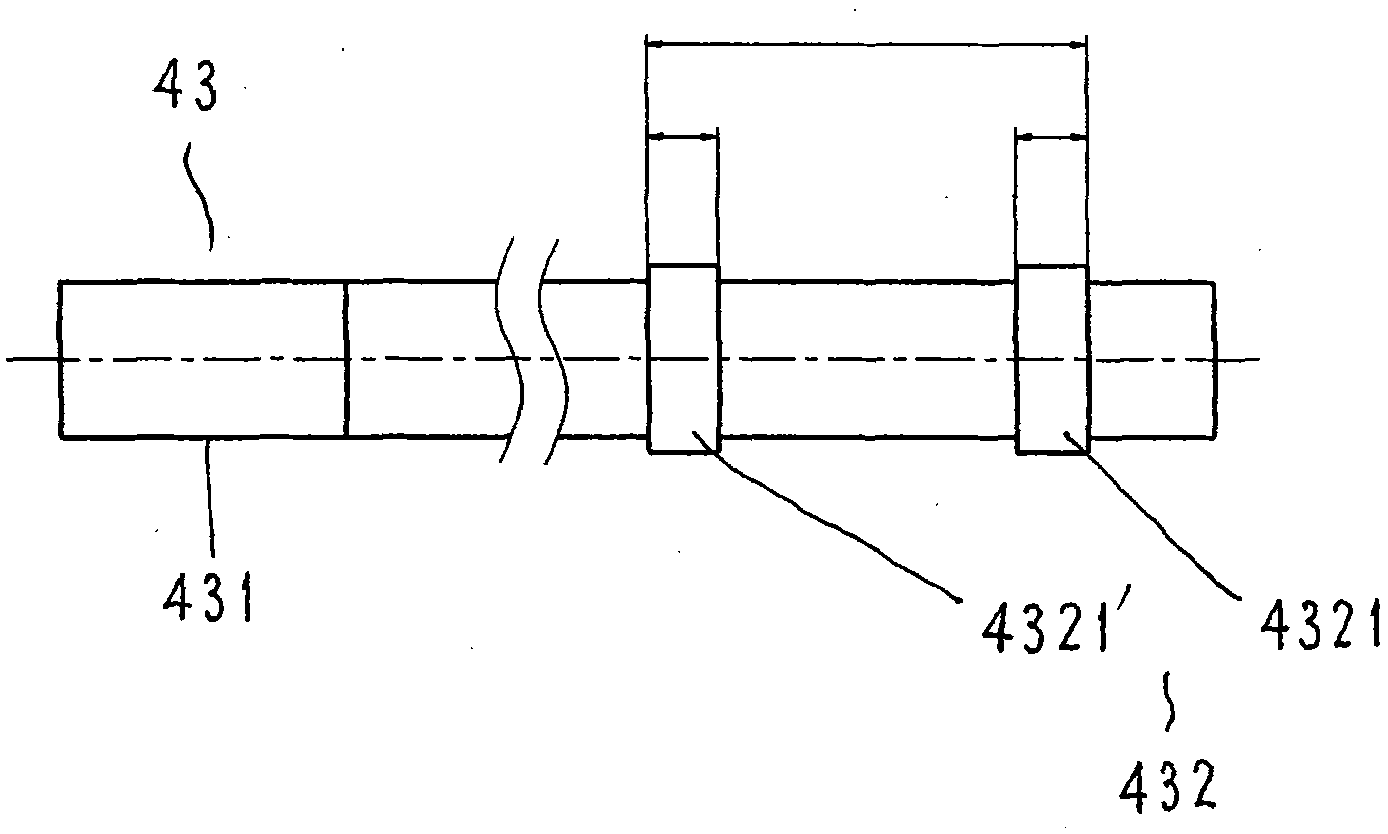

[0015] Reference figure 1 , The electro-erosion processing valve sleeve full peripheral process device includes a transmission mechanism 1, an oil tank 2, a valve sleeve 3 and an electrode assembly 4.

[0016] The transmission mechanism 1 includes a bracket 11, a motor 12, a transmission belt 13 and a transmission shaft 14, in which:

[0017] The bracket 11 is composed of upper and lower fixing plates and a frame body. The upper fixing plate is used to fix the motor 12, and the lower fixing plate can be fixed at the bottom of the oil tank 2;

[0018] The motor 12 is used to drive the workpiece (valve sleeve) to rotate, and a toothed belt wheel is fixed on the shaft extension of the motor 12, and a transmission belt 13 is engaged and sleeved on the toothed belt wheel;

[0019] The transmission belt 13 is a toothed belt with two-stage deceleration. The first-stage driven wheel and the second-stage driving wheel are coaxial. The shaft is fixed on the bracket 11, and the second-stage driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com