Fixture for milling axially-overlapped thin-wall disc type workpieces

An axial overlap and fixture technology, applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of long time for tightening the platen screws, difficulty in ensuring processing requirements, and inability to uniform pressure, achieving simple structure, The effect of low manufacturing cost and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

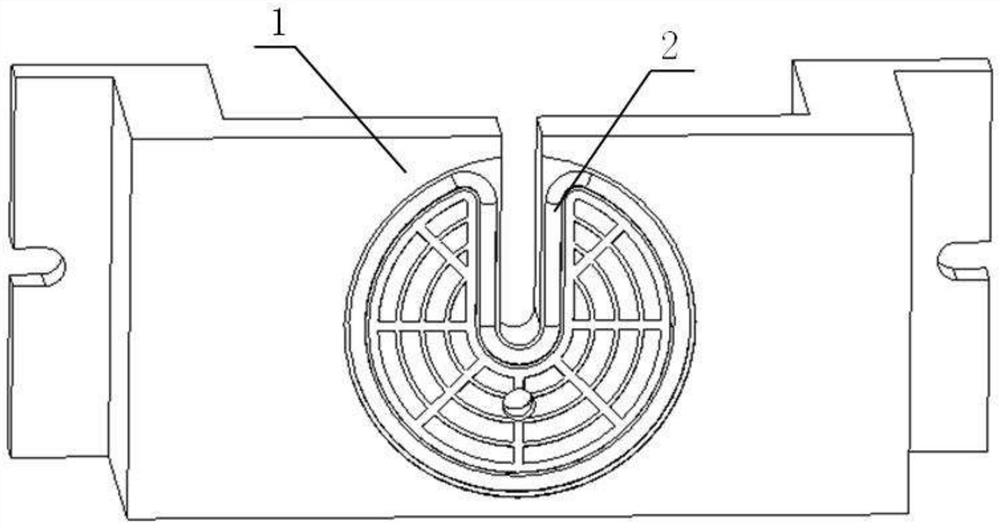

[0020] Such as figure 1 as shown, figure 1 It is a structural view of the jig for milling thin-walled disc workpieces with overlapping axial distribution;

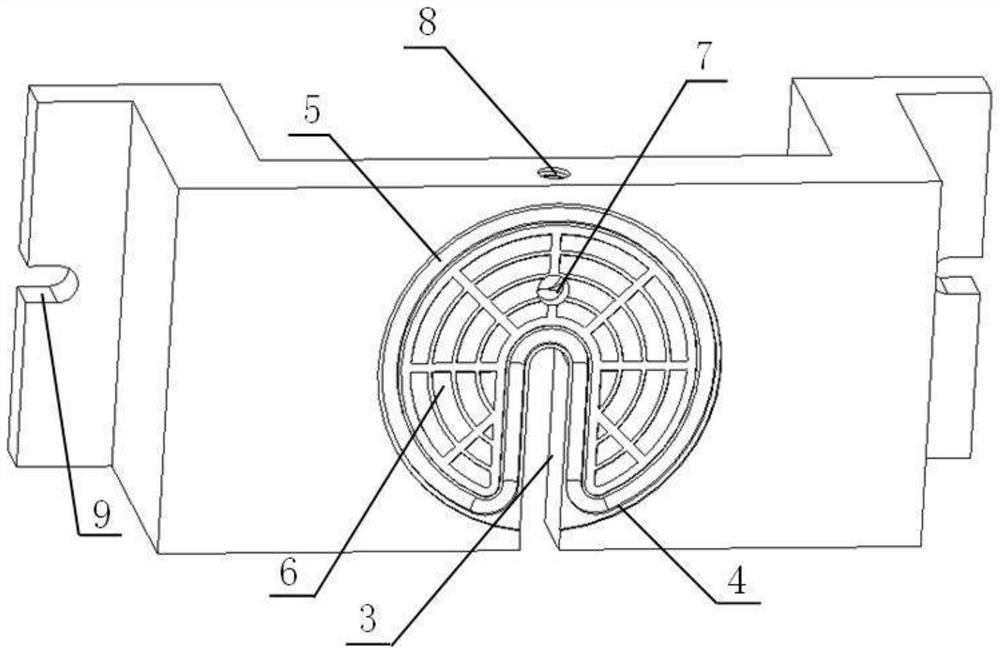

[0021] Such as figure 2 as shown, figure 2 It is a structural view of the fixture main body; the fixture main body 1 includes a workbench and pillars symmetrically arranged on both sides of the workbench, and the space formed in the middle is used to avoid the rest of the parts that are not clamped. A notch 9 for clamping and fixing is provided on the pillar, a circular positioning groove 4 and an opening groove 3 are arranged on the worktable, the circular positioning groove 4 is formed by sinking the end face of the worktable, and The diameter of the circular positioning groove 4 is set in cooperation with the diameter of the thin-walled disc workpiece for accurate positioning of the thin-walled disc workpiece.

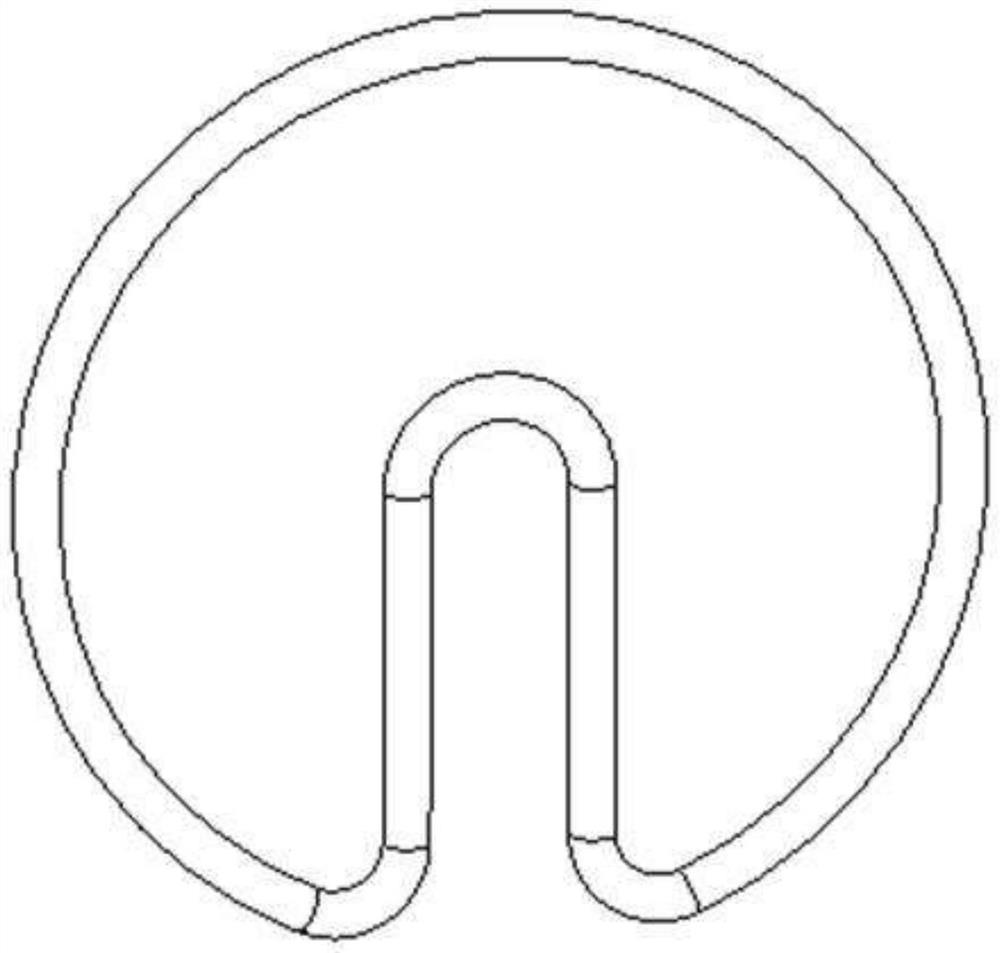

[0022] The opening groove 3 extends linearly from the center of the circular positioning groove 4 to th...

Embodiment 2

[0030] Such as Figure 4 as shown, Figure 4 It is a schematic diagram of the use of the fixture for milling thin-walled disc workpieces with overlapping axial distribution; during processing, the connection joint 10 of the vacuum pump is connected to the threaded hole 8, and the fixture main body 1 is fixed through the gap 9, The part 11 is clamped on the fixture main body 1 through the opening groove 5, and the disc to be processed of the part 11 is fixed on the circular positioning groove 4, and the vacuum pump valve is opened, and gently pressed by hand It is determined whether the disc to be processed of the part 11 is clamped flat, so as to complete the whole process of positioning and clamping of the quick clamp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com