Composite clutch

A clutch and composite technology, applied in the direction of clutches, friction clutches, mechanical drive clutches, etc., can solve the problems of excessive transient impact force and the difficulty of achieving absolute coaxiality of parts, so as to increase the transmission torque, Solve complex problems and have huge market potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

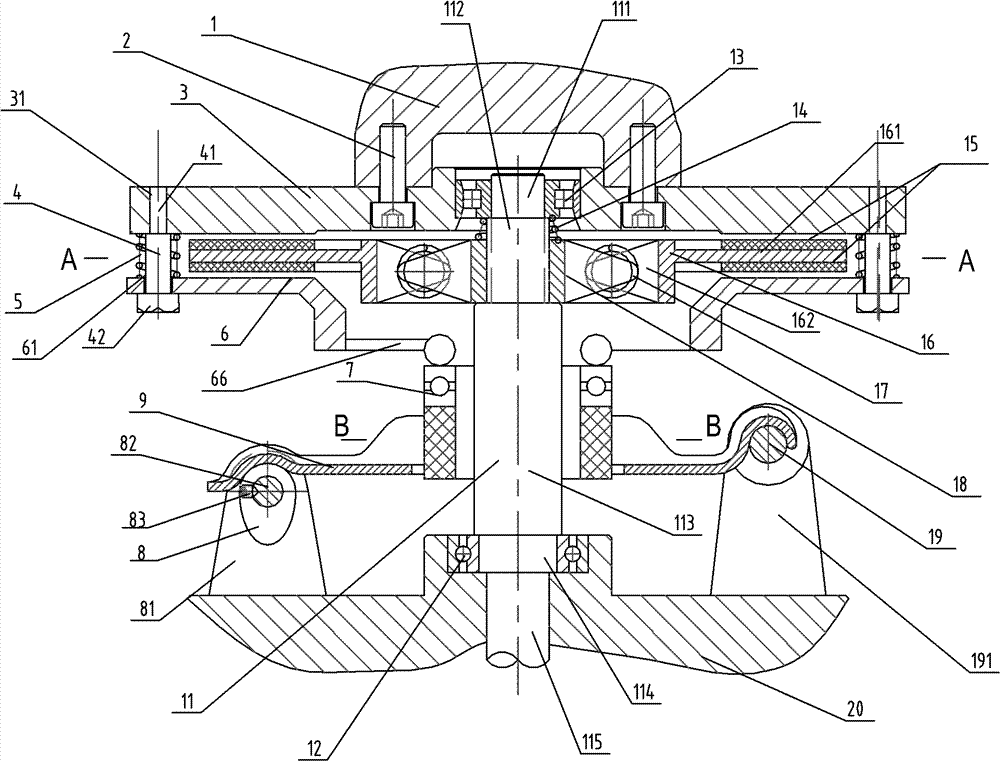

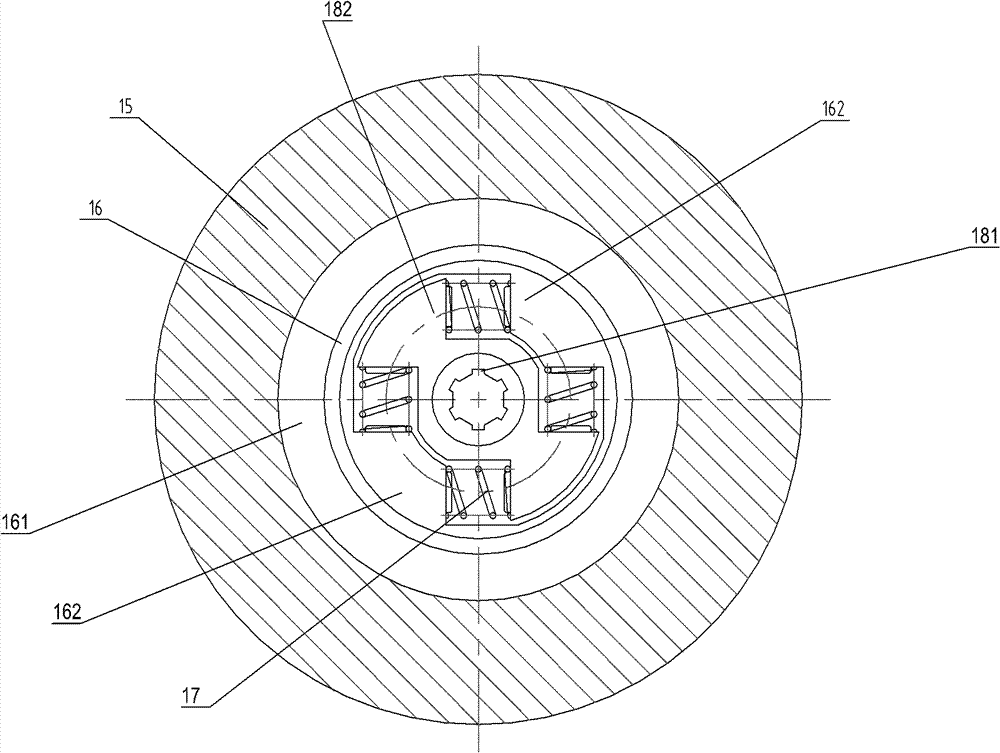

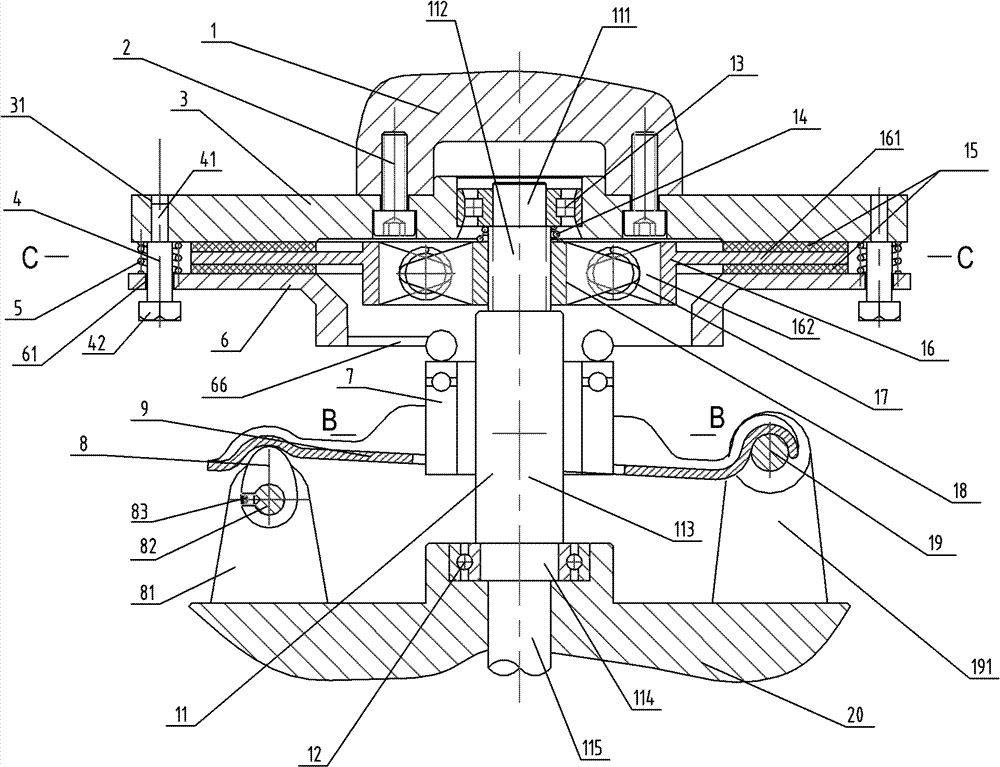

[0020] Figure 1~Figure 5 A composite clutch is given, which includes a main friction disc 3, a double-sided shaft friction disc 15, a secondary friction disc 6, a plane bearing fork body 7 and a base 20 arranged in sequence from top to bottom. The main friction disc 3 is fixedly connected with the bottom end of the high-speed moving part 1 through at least three countersunk screws 2 .

[0021] A guide rail 4 is set between the main friction disc 3 and the secondary friction disc 6, specifically as follows: three round holes 31 are provided near the outer circumference of the main friction disc 3, and three sets of guide rails 4 are installed correspondingly for fastening, The small head 41 of the guide plug 4 is used to be fastened and installed in the above-mentioned circular hole 31 (that is, the small head 41 of the guide plug 4 is fixedly connected with the main friction disc 3 ). The outer surface of the middle section of the guiding guide 4 is set with a return spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com