Method for marking multiple components

A technology for parts and markings, applied in the general control system, comprehensive factory control, program control, etc., can solve problems such as increasing the difficulty of communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Detailed description of the preferred embodiment

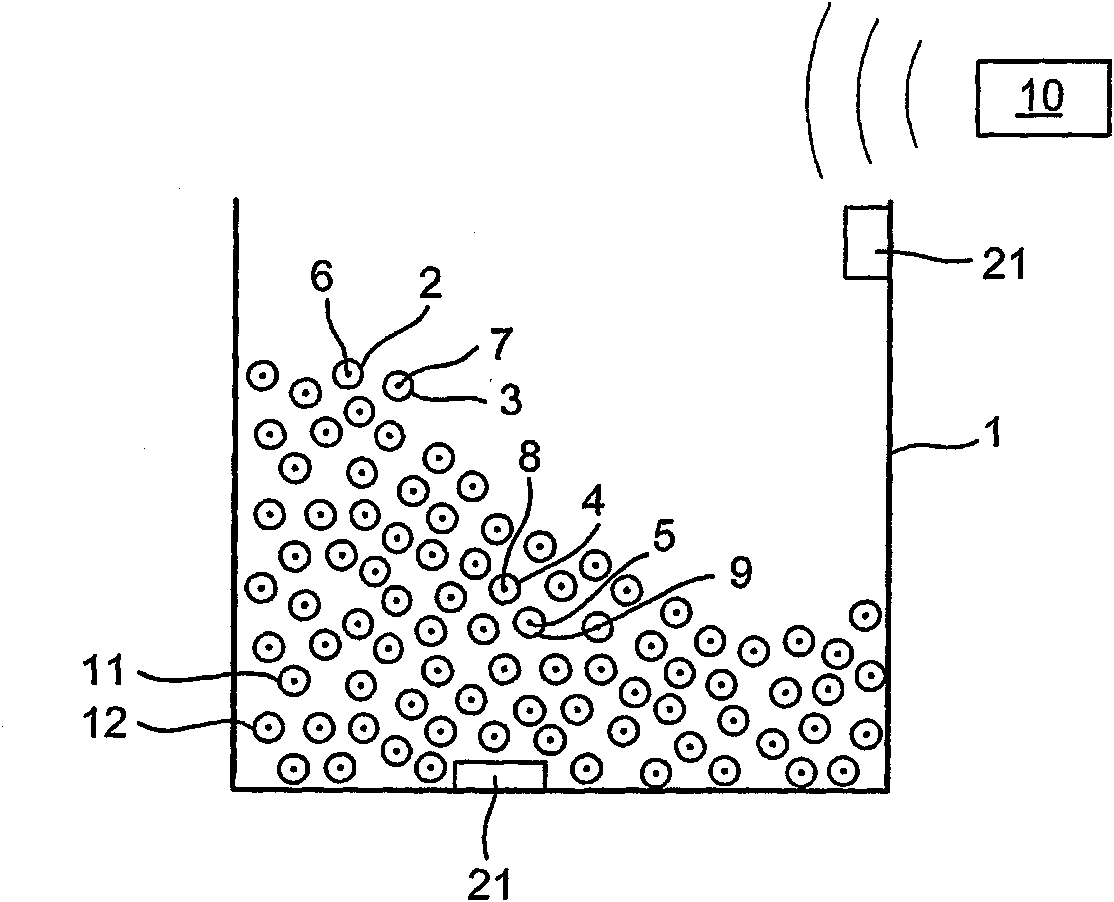

[0045] figure 1 Shown is a schematic view of a metal silo 1 partially filled with a group of parts comprising parts 2, 3, 4, 5, 11, 12, which are bulk pieces placed loosely from each other and each composed of A material, such as metal, that at least partially shields electromagnetic waves.

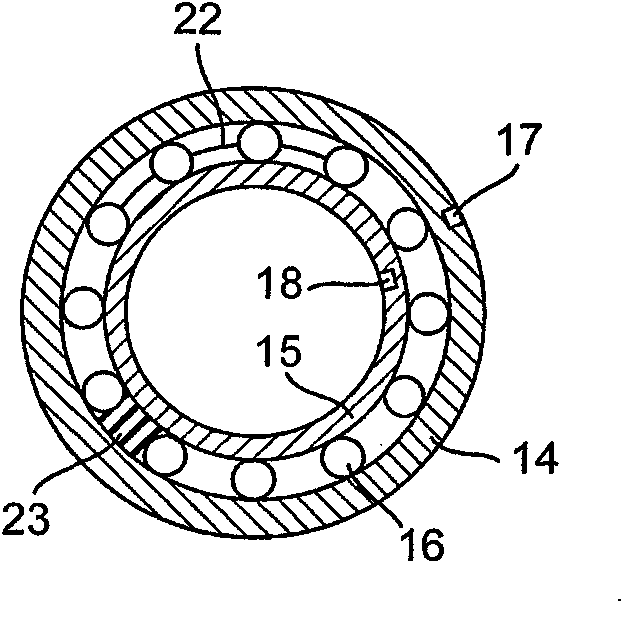

[0046] The part can be, for example, a rolling bearing comprising metal components or consisting entirely of metal parts.

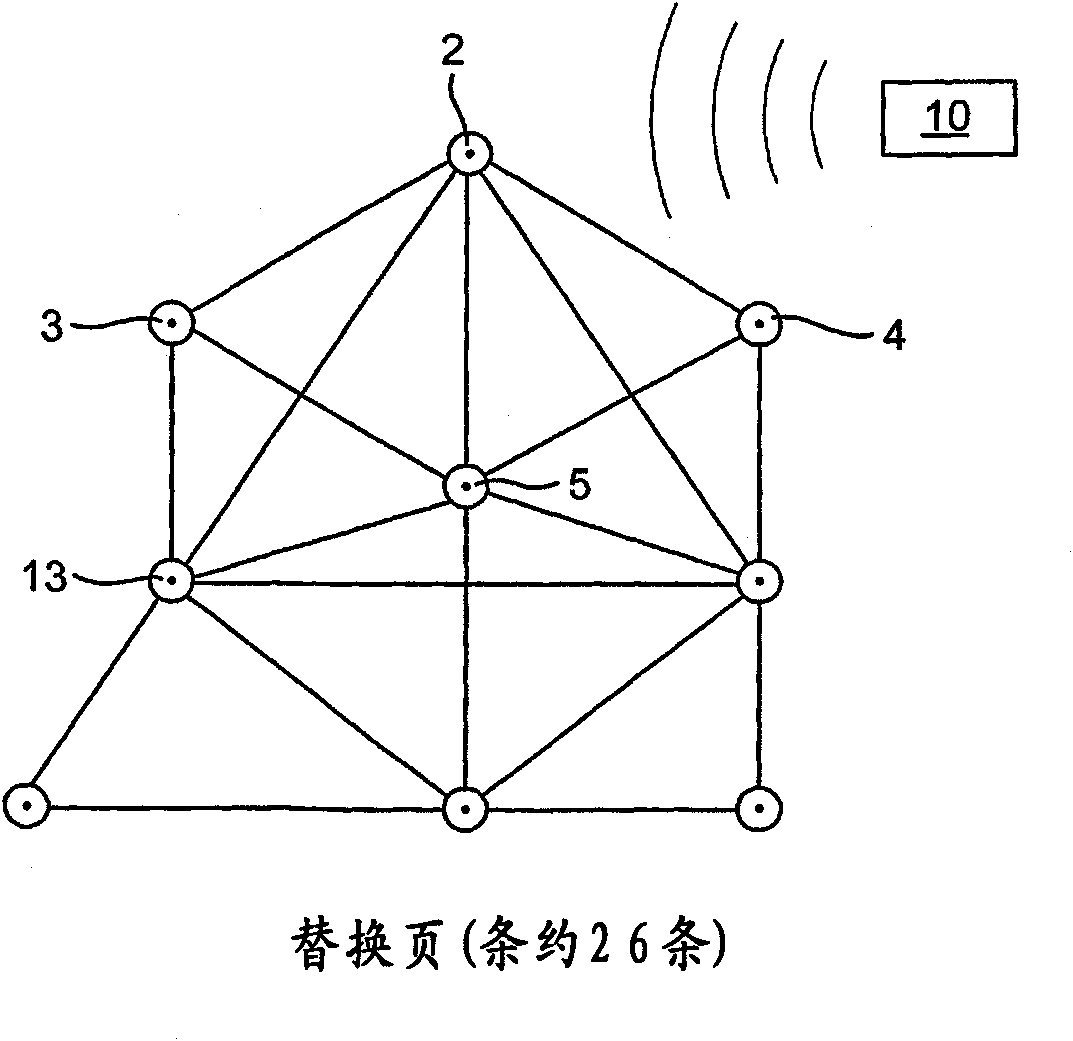

[0047] Each part carries at least one transponder and one storage device. In the figure, each transponder together with the corresponding storage device is schematically drawn as a point in the middle of the part. Such transponders can receive and transmit signals. In the case of RFID transponders, a so-called air interface is provided in the radio frequency area simultaneously with the use of electromagnetic waves. However, other radio signals are also conceivable for conveying information. In principle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com