Bending fatigue testing machine for instep belt

A technology of bending fatigue and instep straps, which is applied in the field of footwear testing equipment, can solve the problems that the instep straps cannot be truly simulated and loosened, and the detection results are not scientific and reasonable, and achieve scientific and reasonable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

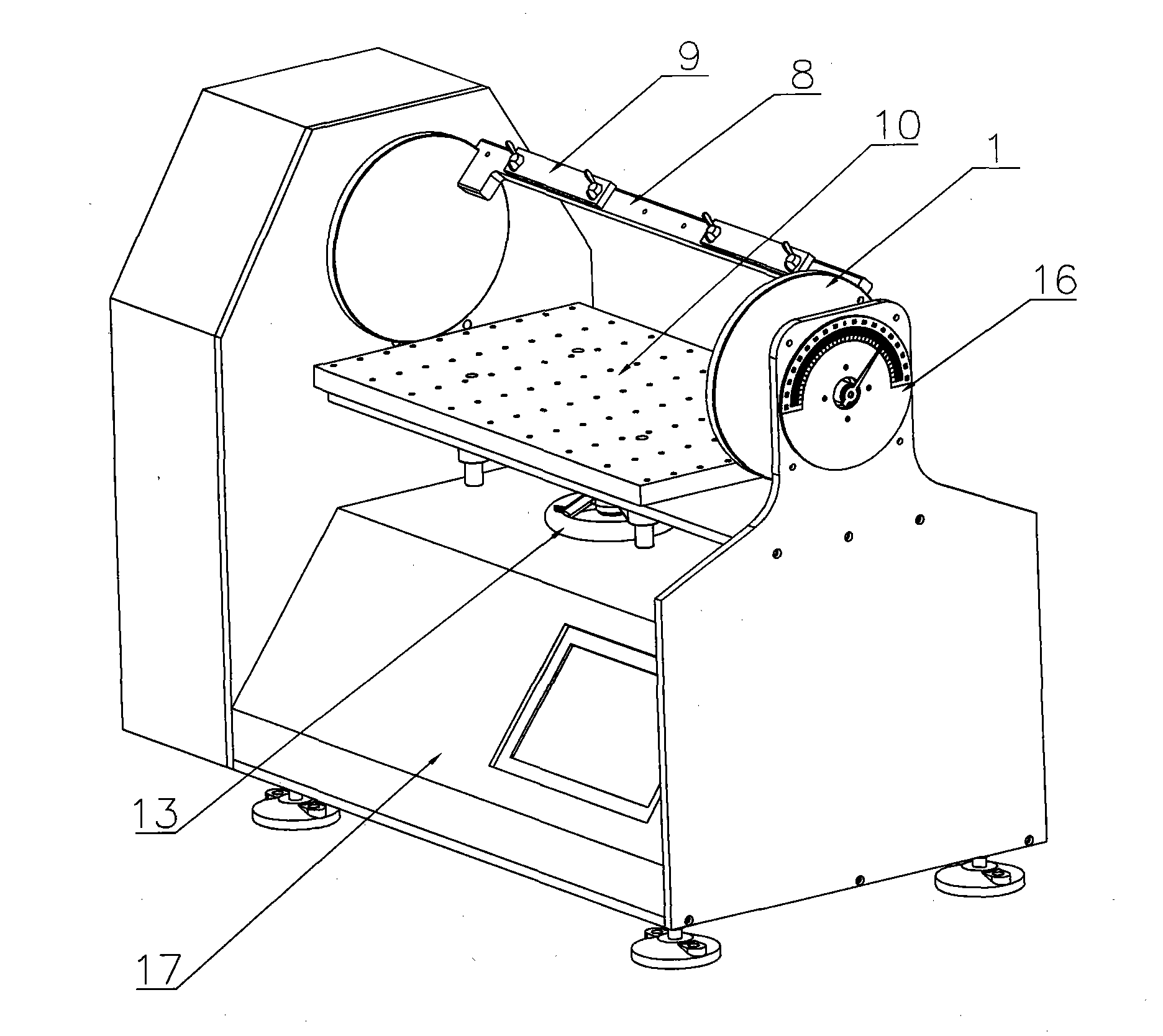

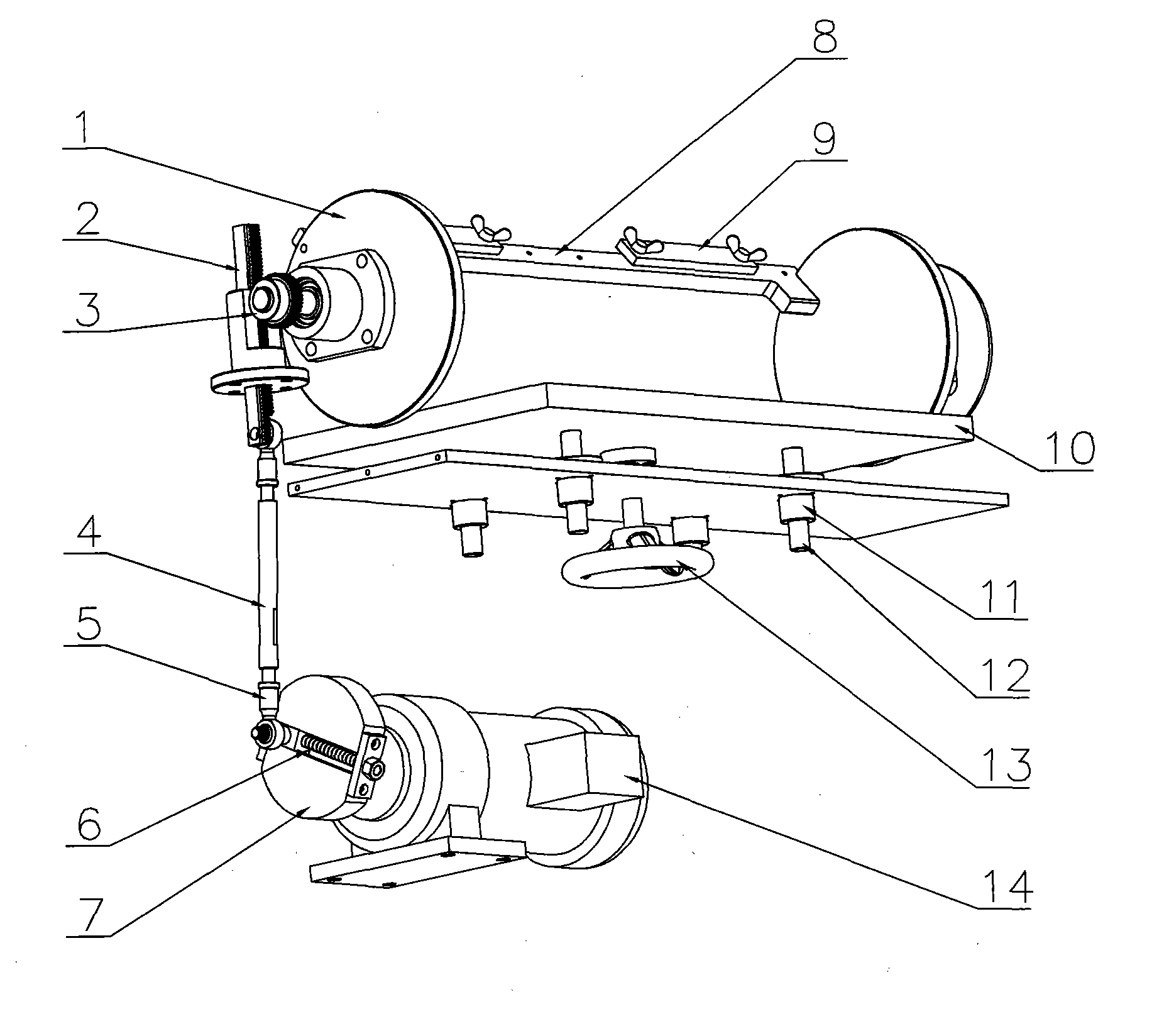

[0018] Such as figure 1 and figure 2 As shown, the instep belt bending fatigue testing machine of the present invention includes a machine base 17, a control box, a shoe placement plate 10 that can be adjusted up and down, a disc 1 that is rotatably arranged on the machine base 17, and is used for clamping the instep. A crossbeam 8 with an open end that can swing back and forth in a circular arc around the center of the disc 1, a drive motor 14, and a transmission mechanism for making the disc 1 reciprocate in a circular arc around the center of the disc 1; the drive motor 14 is set On the base 17, the driving motor 14 is drivingly connected to the transmission mechanism, the transmission mechanism is drivingly connected to the disc 1, and the control box is connected to the driving motor 14 under control. Further, the crossbeam 8 is provided with a pressing block 9 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com