Leather bursting tester

A testing machine and leather technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of unscientific and reasonable test results, long clamping time, inconvenient testing, etc., and achieve high testing efficiency and clamping Convenience, scientific and reasonable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

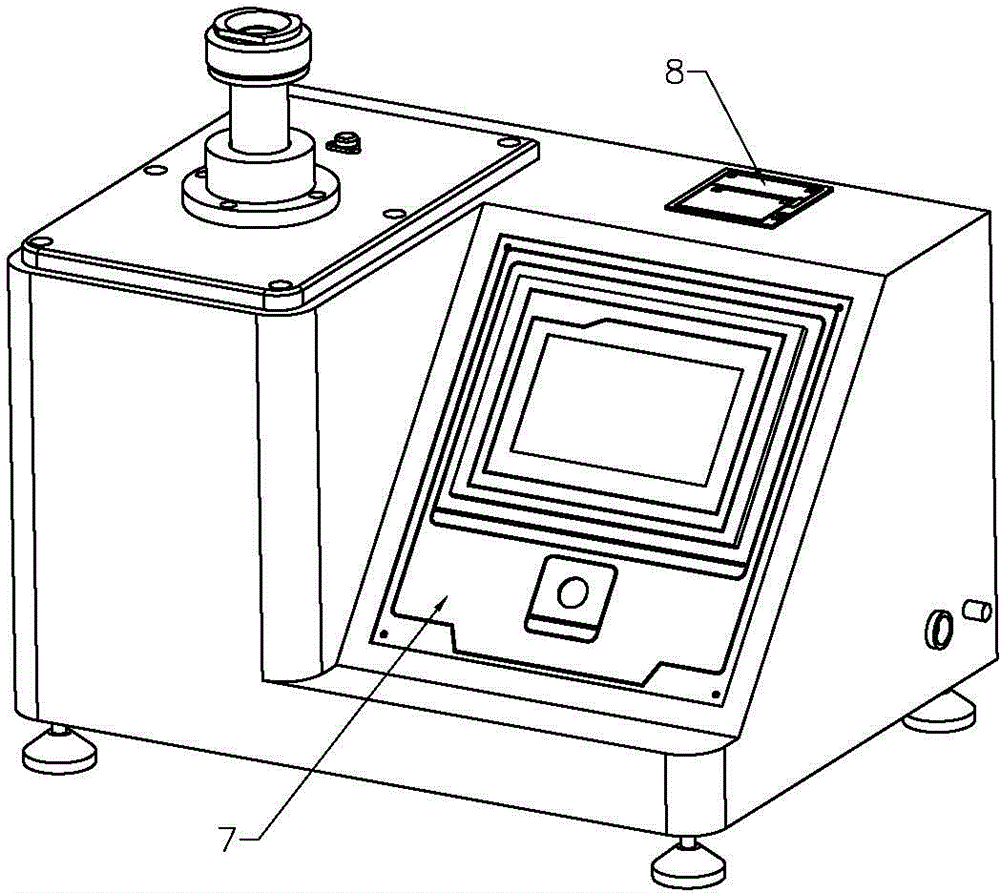

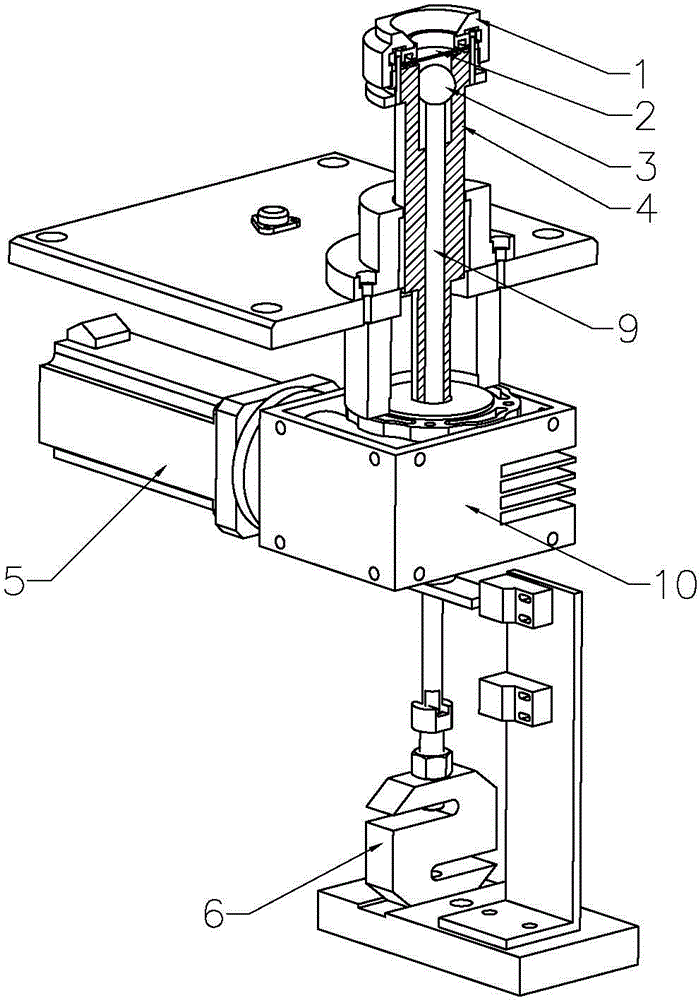

[0010] Below in conjunction with accompanying drawing, the present invention will be further described: figure 1 and figure 2 As shown, the leather cracking tester of the present invention includes a test system with a touch screen 7, a printer 8, a motor 5, a reducer 10, a hollow fixture seat 4 and a top rod 9 with a steel ball 3 on the top; The touch screen 7 is used to set the maximum measurement force and test speed, the motor 5 drives and connects the reducer 10, the reducer 10 drives the clamp seat 4 to move up and down, the ejector rod 9 is arranged in the internal hollow position of the clamp seat 4, and The push rod 9 is fixed, the top of the clamp seat 4 is threadedly connected with a nut 1, and the sample 2 is fixed on the clamp seat 4 with the nut 1; the bottom of the push rod 9 is provided with a force sensor for inductive force value; The clamp seat 4 is provided with a scale value of moving height relative to the push rod 9, which can also be used for observin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com