Protective gas airtight circulation crushing apparatus and crushing process

A technology of protective gas and crushing equipment, which is applied in the field of airflow crushing equipment, protective gas closed cycle crushing process, and protective gas closed cycle crushing equipment, which can solve the problem of explosion, airflow crushing equipment and crushing process without dangerous goods, and dangerous goods. Inapplicable and other problems, to achieve the effect of reducing pollution, ensuring health and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

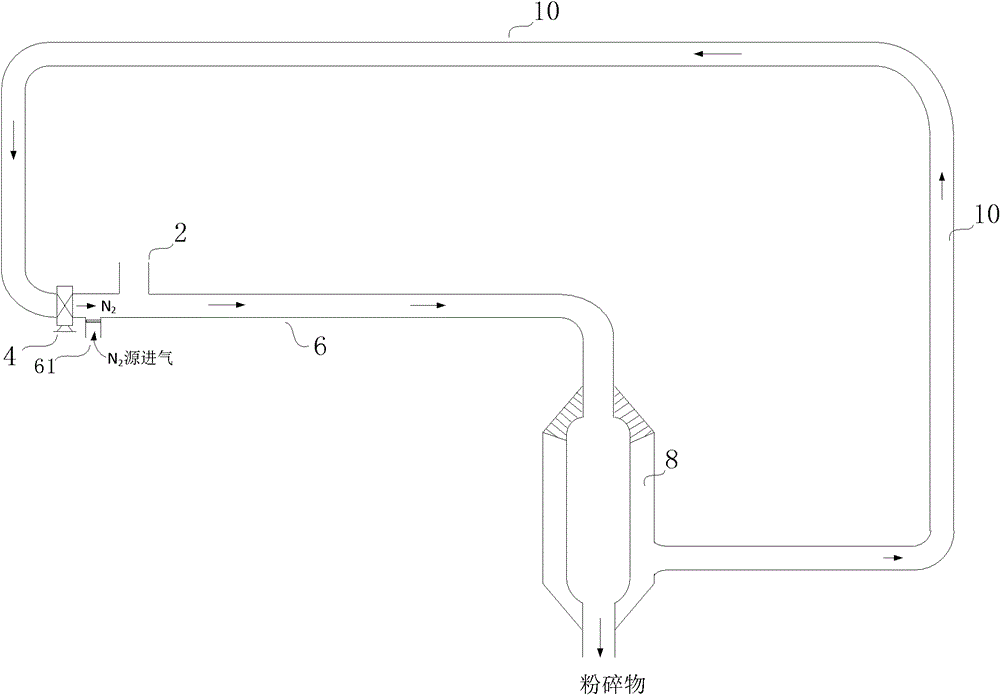

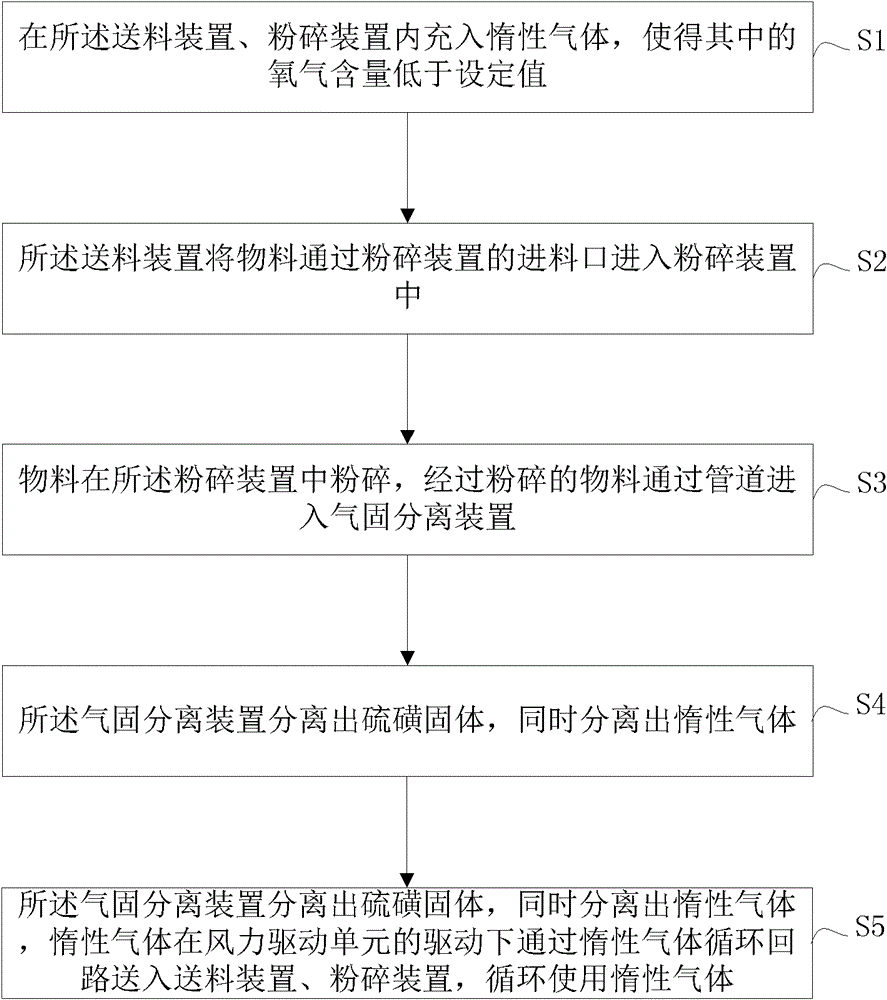

[0034] see figure 1 , The present invention discloses a protective gas closed circulation pulverization equipment, the pulverization equipment is airtightly arranged;

[0035] The crushing equipment is provided with an inert gas inlet 61, and the inert gas inlet 61 can also be arranged at other positions.

[0036] The feeding device, the crushing device 6 and the gas-solid separation device 8 are sequentially connected; the feeding device feeds the material into the feed port 2 of the crushing device 6 . The gas in the feeding device and the pulverizing device 6 are all inert gases; in this embodiment, the inert gas is nitrogen.

[0037] The gas-solid separation device 10 separates sulfur solids and inert gases at the same time. The gas-solid separation device 10 may be a vortex separator or a centrifugal separator or the like.

[0038] The inert gas circulation loop 10 sends the inert gas separated from the gas-solid separation device 40 into the feeding device and the cru...

Embodiment 2

[0051] In this embodiment, the crushing equipment and crushing process of the present invention can be used to crush other inflammable and explosive dangerous articles except sulfur, and can also be used to crush ordinary articles.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap