Mine cableway conveyed by roller chain

A technology of chain conveying and rollers, applied in the field of mine aerial ropeway, can solve the problems of easy failure, low transmission efficiency, rope drop, etc., and achieve the effects of avoiding flying cars, high transmission efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

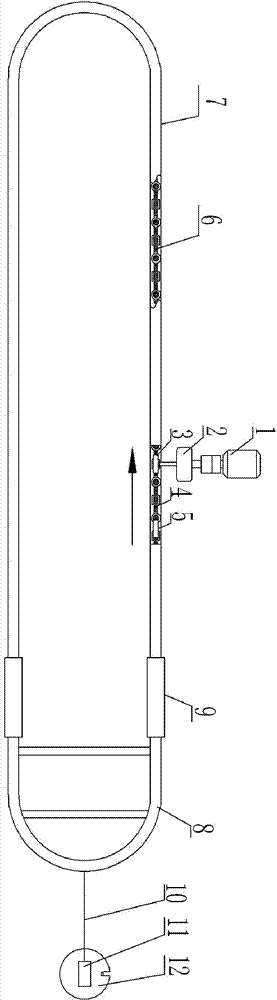

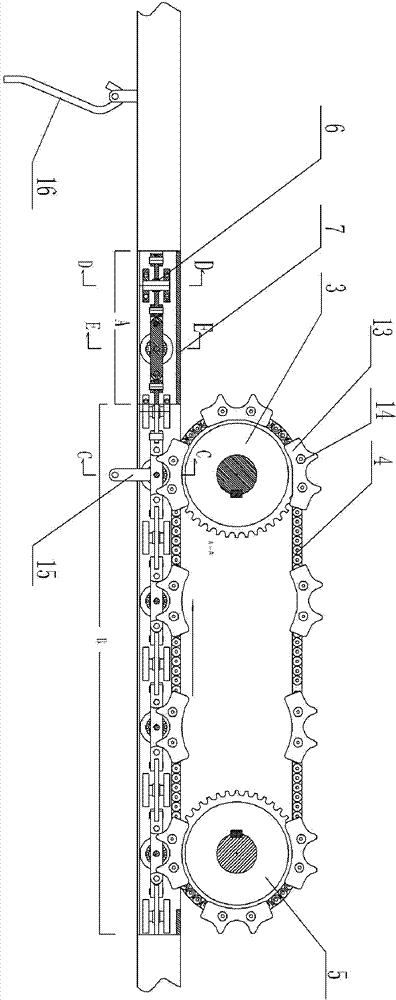

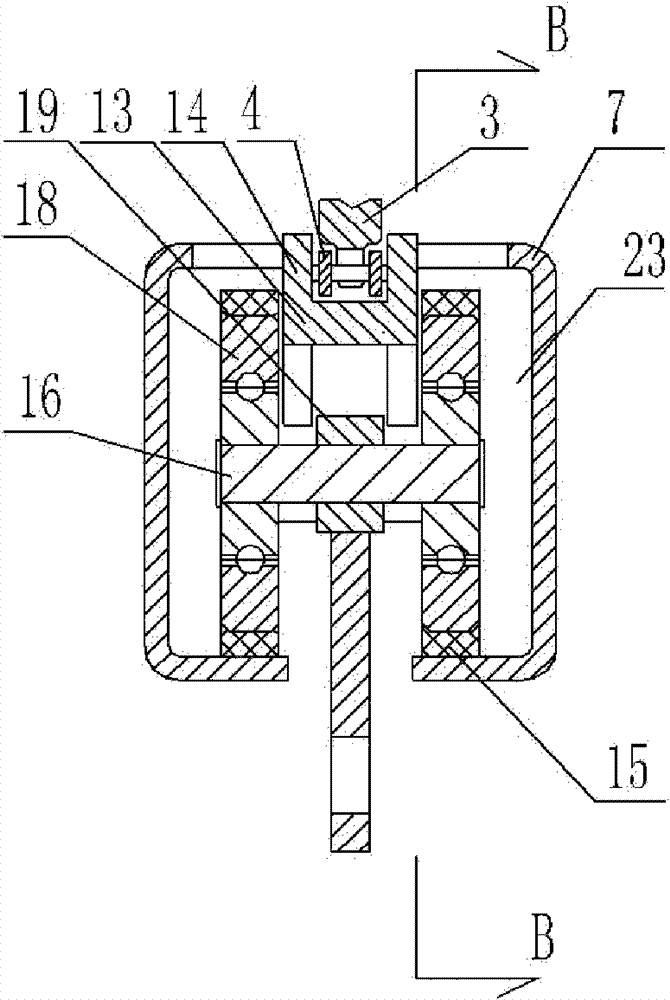

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Picture 9 , Picture 10 As shown, a mine ropeway conveyed by a roller chain consists of a power part, a conveyor chain and a guide rail 7. The power part includes a motor 1, a reduction box 2, a main sprocket 3, a slave sprocket 5, a main sprocket 3 and a slave The sprocket 5 is linked by a chain 4, and a chain pawl 13 is installed on the chain 4 through a chain pin 14; the conveyor chain is formed by connecting a roller chain ring and a two-way joint 17 with each other. The roller chain ring includes a connecting plate 19, The connecting plate 19 is equipped with a roller shaft 16, and a roller 18 is installed on the roller shaft 16, a connecting plate pin hole 24 is opened at both ends of the connecting plate 19, and two ends of the two-way joint 17 are opened with mutually perpendicular connecting grooves 20. The connecting groove 2 is provided with a joint pin hole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com