Laser cutting method and equipment, with means for modifying the laser beam quality factor by a diffractive optical component

An optical device, diffractive optics technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of poor performance and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

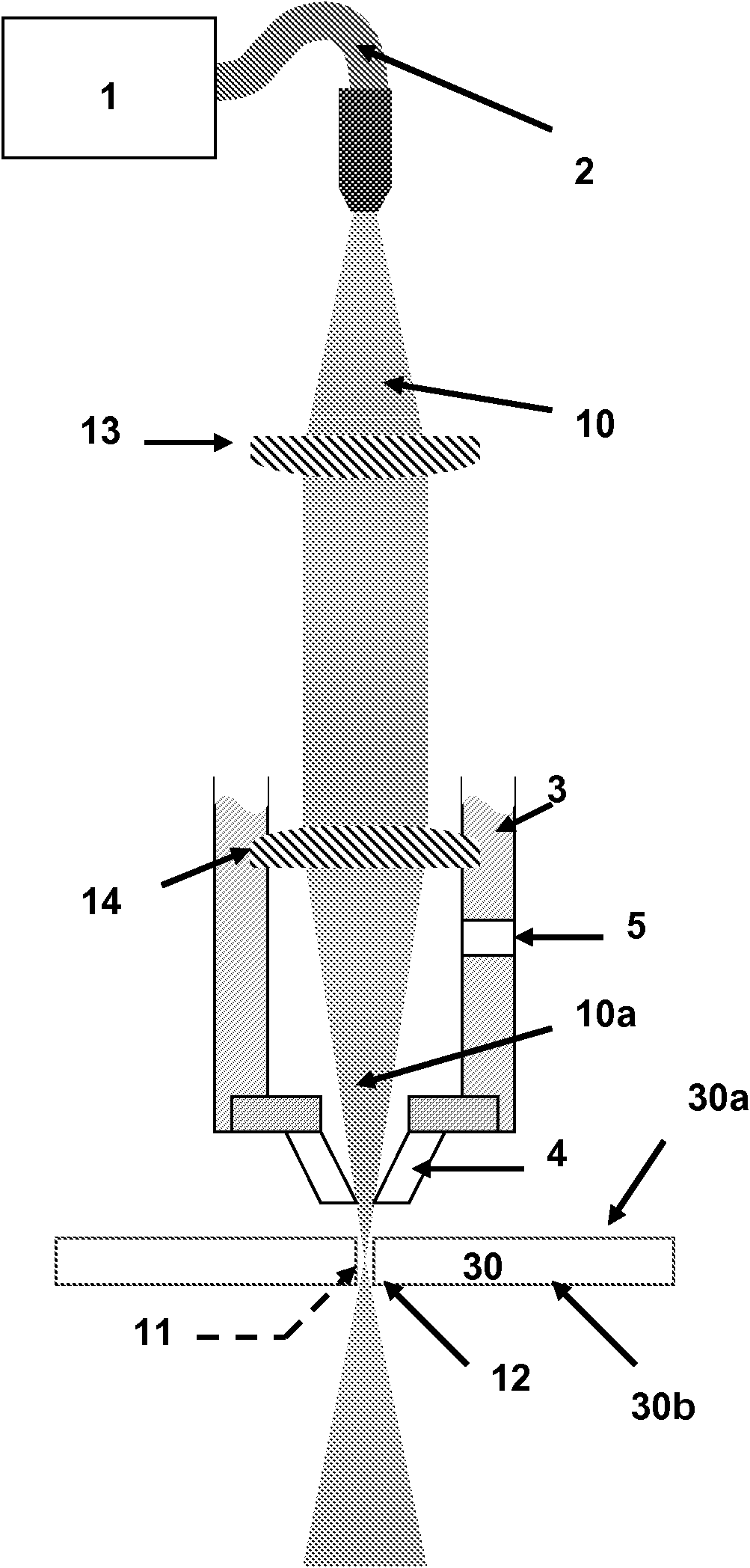

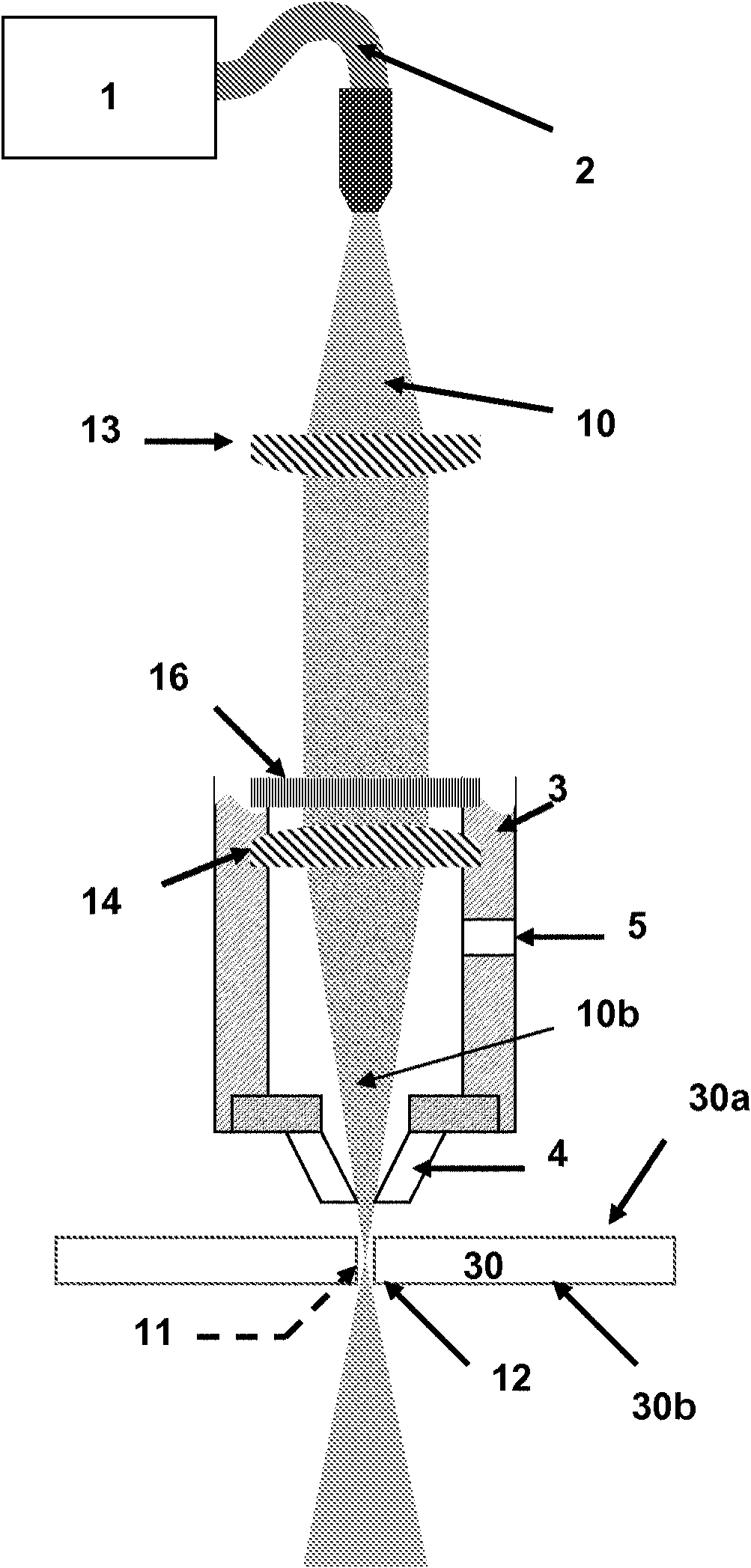

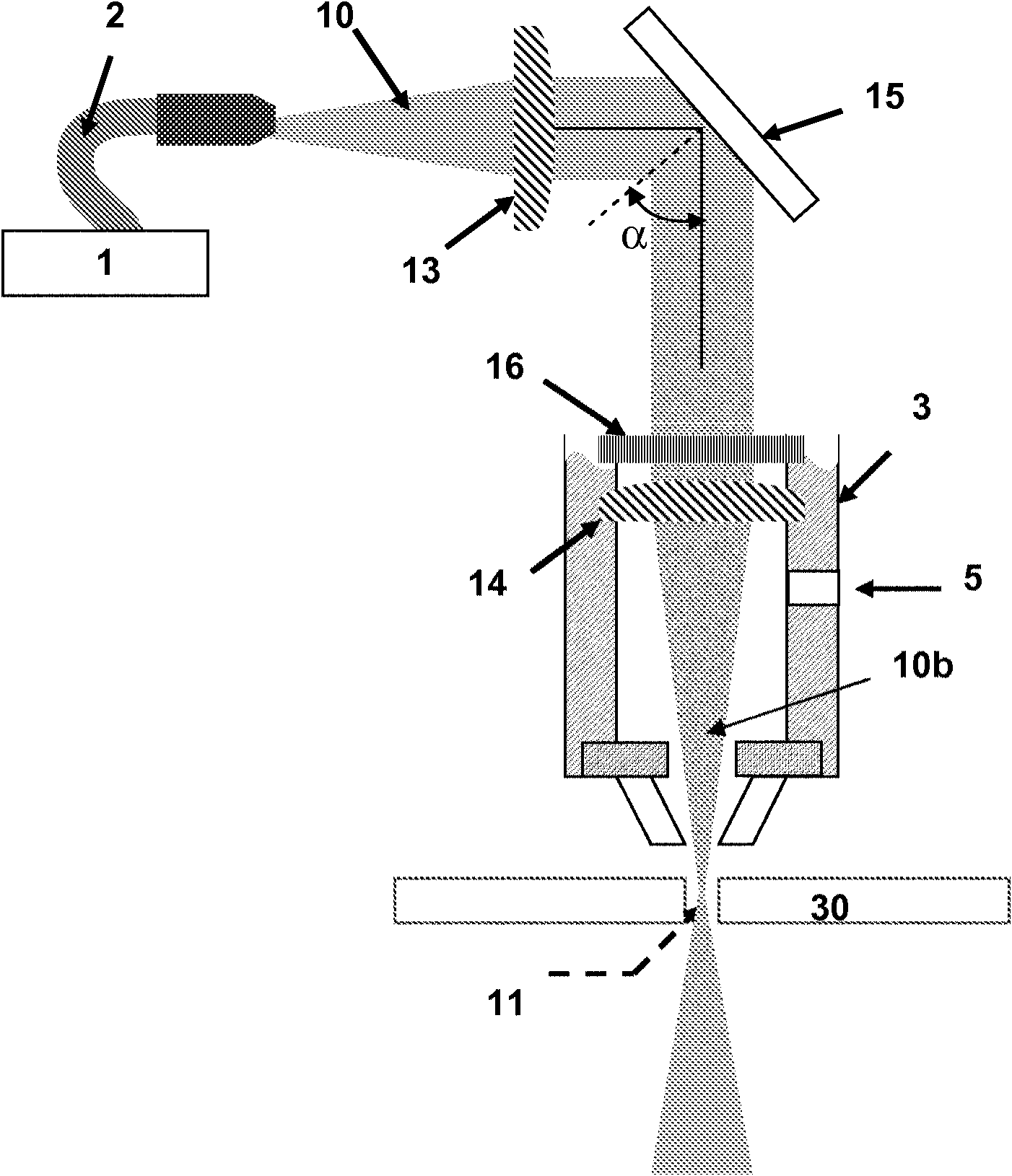

[0042] Such as Figure 1-4 As shown in and 9, for cutting with a laser beam 10, a laser cutting unit is generally used comprising a laser source 1, also called a laser generator or a laser device, which is coupled to a delivery fiber 2 in order to generate an incident laser beam 10, said incident laser beam 10 propagates to a focusing head 3 comprising a laser nozzle 4 disposed facing a workpiece 30 to be cut.

[0043] Advantageously, the laser source 1 is a source consisting of ytterbium-doped fibers, that is to say comprising several fibers containing ytterbium (Yb) or doped with ytterbium, said laser source 1 being used to generate laser radiation. Such ytterbium fiber laser sources are widely commercially available.

[0044] Optionally, the laser source 1 can also be an erbium-doped fiber source.

[0045]The focusing head 3 is supplied with auxiliary gas via a gas inlet 5 provided in the wall of the focusing head 3, and from a gas source such as one or more cylinders, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com