Compact optical system and lenses for prodcuing uniform collimated light

A technology of optical system and lens, applied in the field of optical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

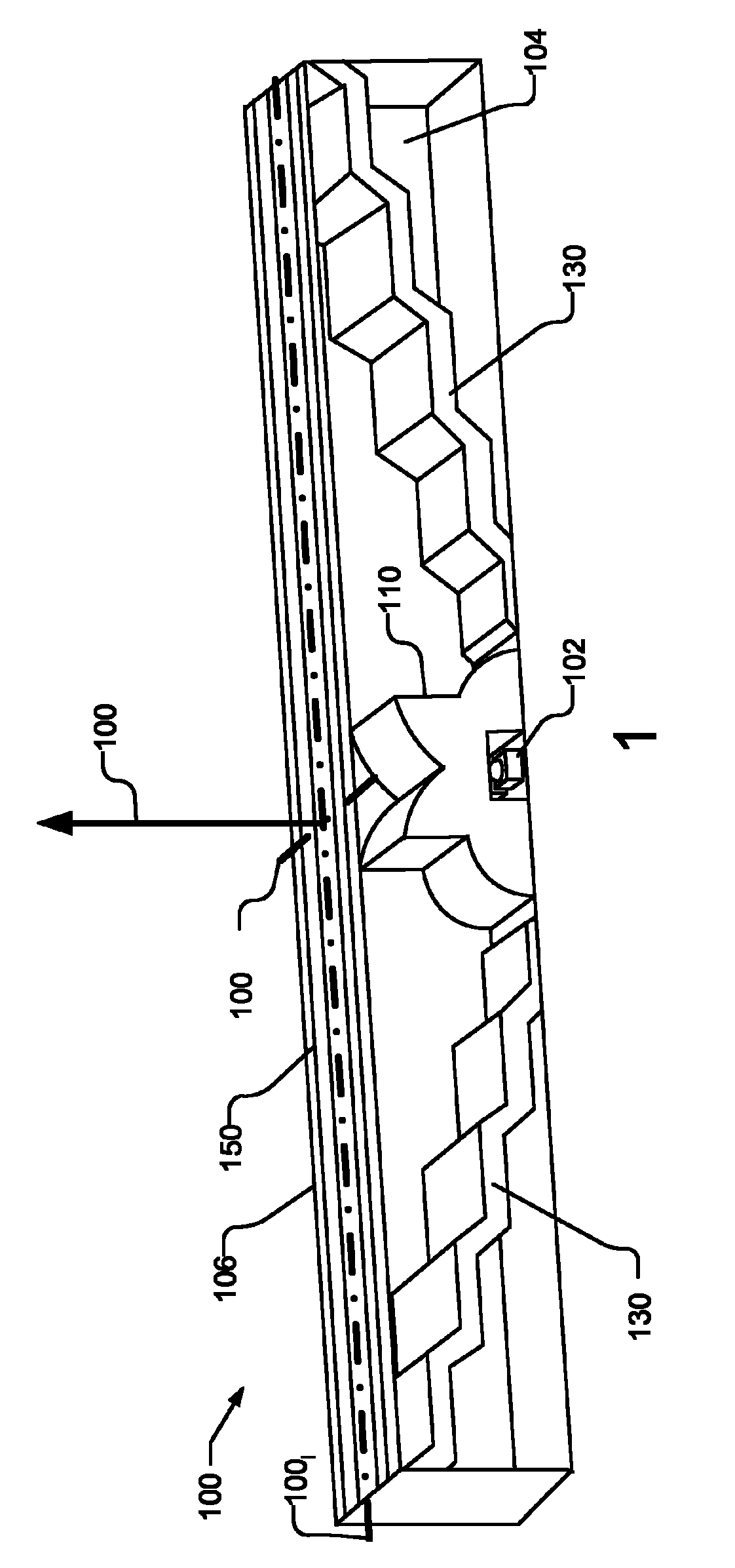

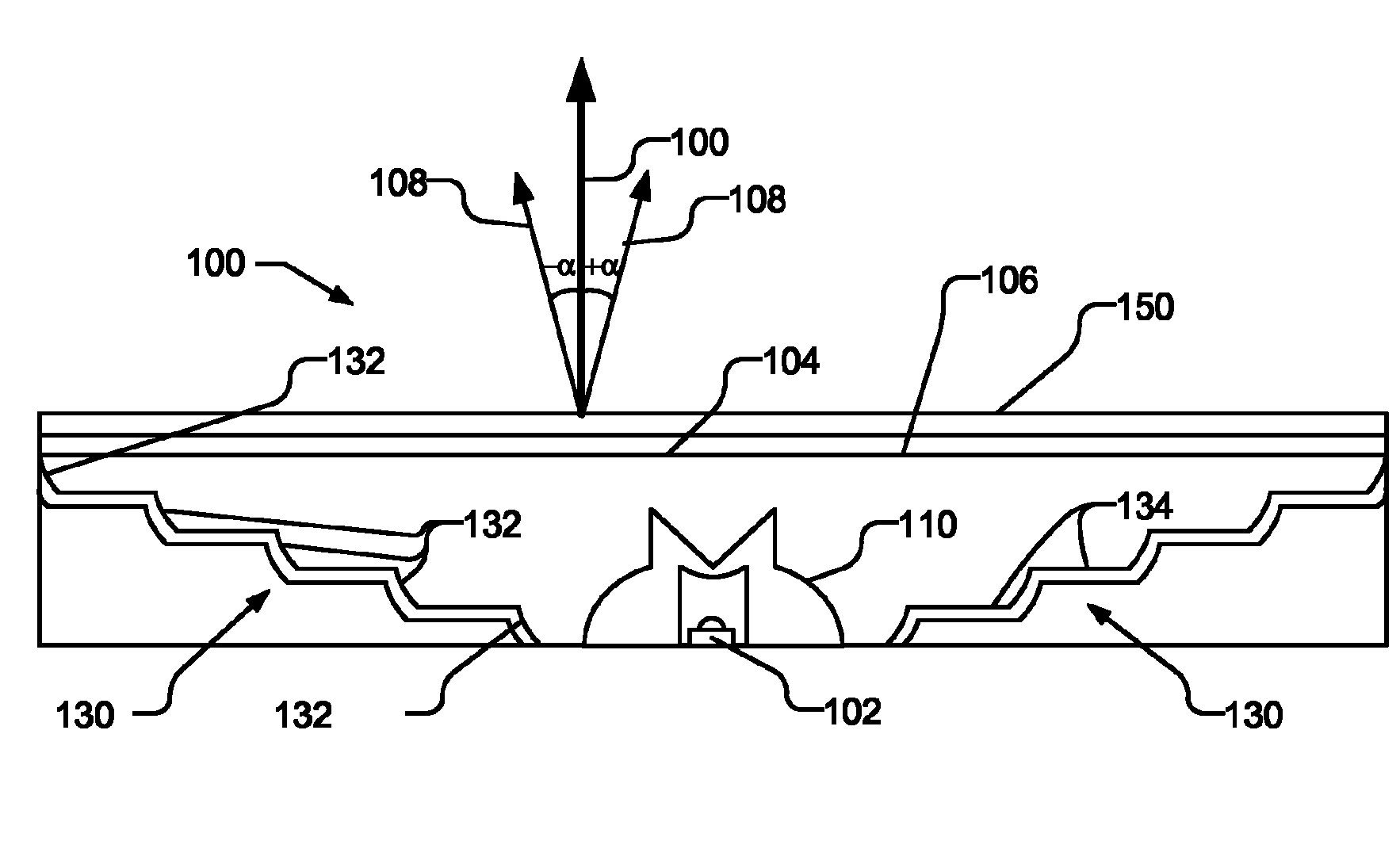

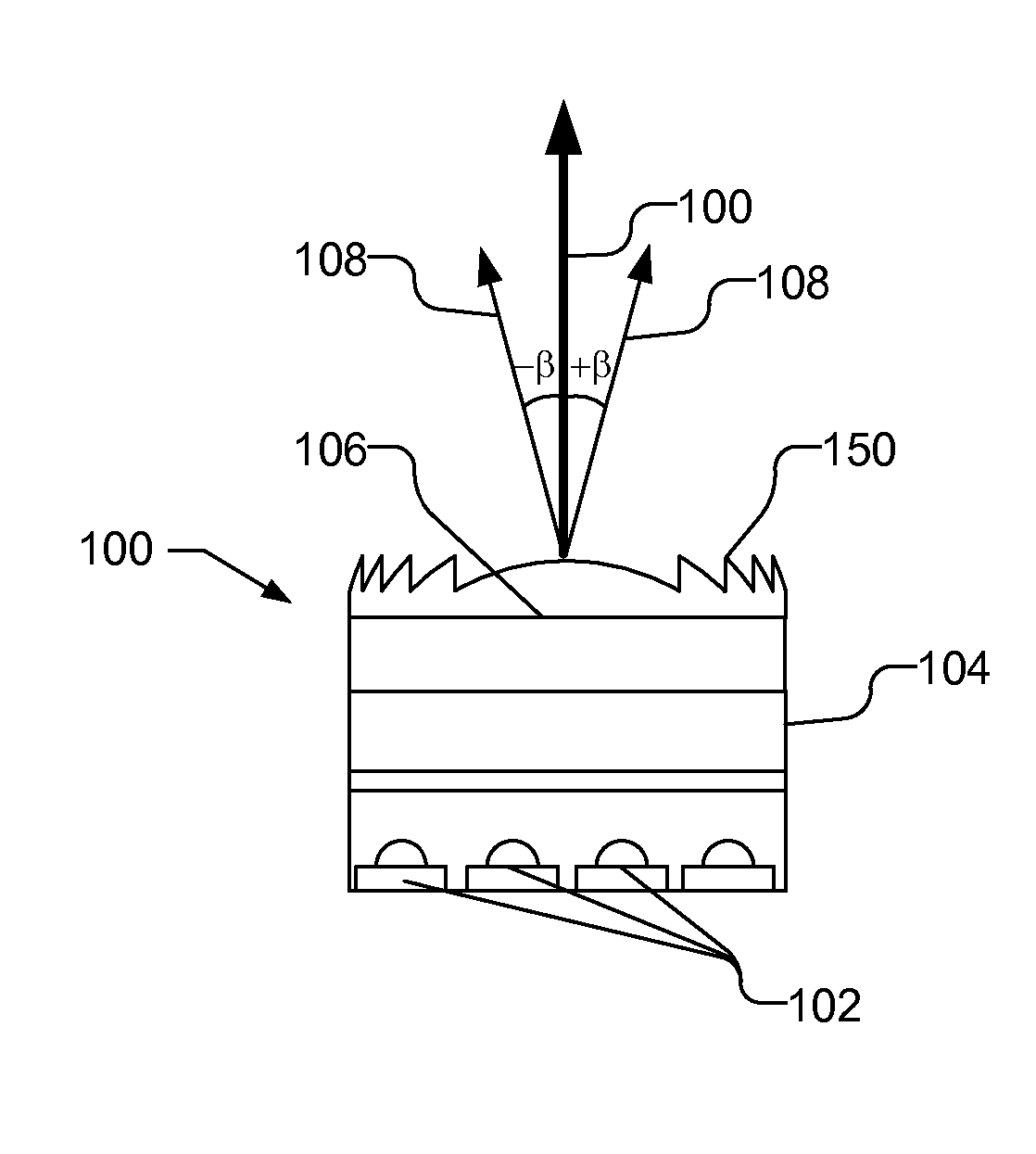

[0010] figure 1 A perspective view illustrating an optical system 100 that may be used with a compact light source, such as a light emitting diode (LED) 102 , in accordance with one embodiment of the present invention. It can be seen that the optical system 100 has a narrow aspect ratio, for example 3:1, but this can be changed as desired. figure 2 and 3 are respectively along the major axis 101 of the optical system 100 long and minor axis 101 short side view. Long axis 101 long and minor axis 101 short orthogonal to each other. The optical system 100 causes the light emitted from the light source to be distributed substantially uniformly throughout the exit window 106 of the optical system 100 and to be strictly collimated, ie directed in a direction substantially perpendicular to the plane of the exit window 106 . It is widely understood in the art that collimated light is not perfectly collimated, but may have some degree of angular spread.

[0011] like image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com