Massage shaft and machining method thereof

An end-shaft, uniform technology, applied in the field of massage shaft and its processing, can solve the problems of unevenness, violent massage action, empty stroke, etc., and achieve the effect of synchronous amplitude and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

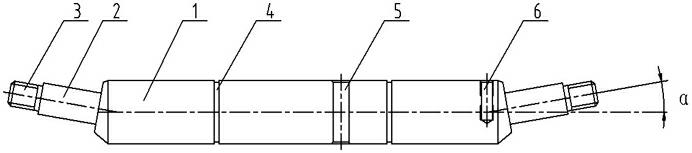

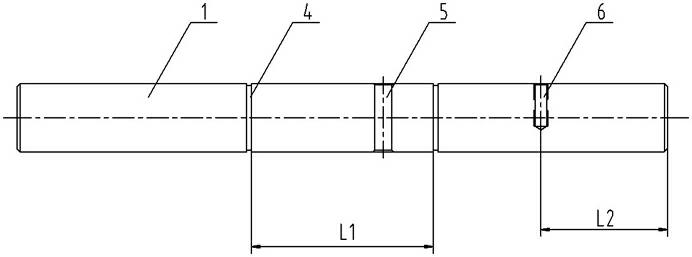

[0033] Embodiment: a kind of massage shaft of this example, as figure 1 , including an intermediate shaft 1 with a length of 129 mm, both ends of the intermediate shaft 1 are connected with an end shaft 2 with a length of 18.5 mm, and a 10 mm threaded head 3 is arranged on the end shaft, and the intermediate shaft, the end shaft, and the threaded head are made of In one piece, the centerlines of the intermediate shaft and the end shafts are on the same plane, and the centerlines of the intermediate shaft and the end shafts are not on the same straight line, and the included angle α between the centerline of the intermediate shaft and the centerlines of the two end shafts is 10°. There are two circlip grooves 4 with a width of 1.35 mm on the intermediate shaft, and a pin hole 5 with a diameter of 5 mm is provided on the intermediate shaft body between the two circlip grooves, and an M4 threaded hole 6 is provided at one end of the intermediate shaft.

[0034] A kind of processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com