High-efficiency weaving and let-off method for double-layer lint

A technology of velvet warp and velvet cloth, which is applied in textiles, papermaking, fabrics, textiles, etc., and can solve problems such as the inability to adjust the height of the velvet, the inability to meet the requirements of double-layer velvet let-off, and the large difference in tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

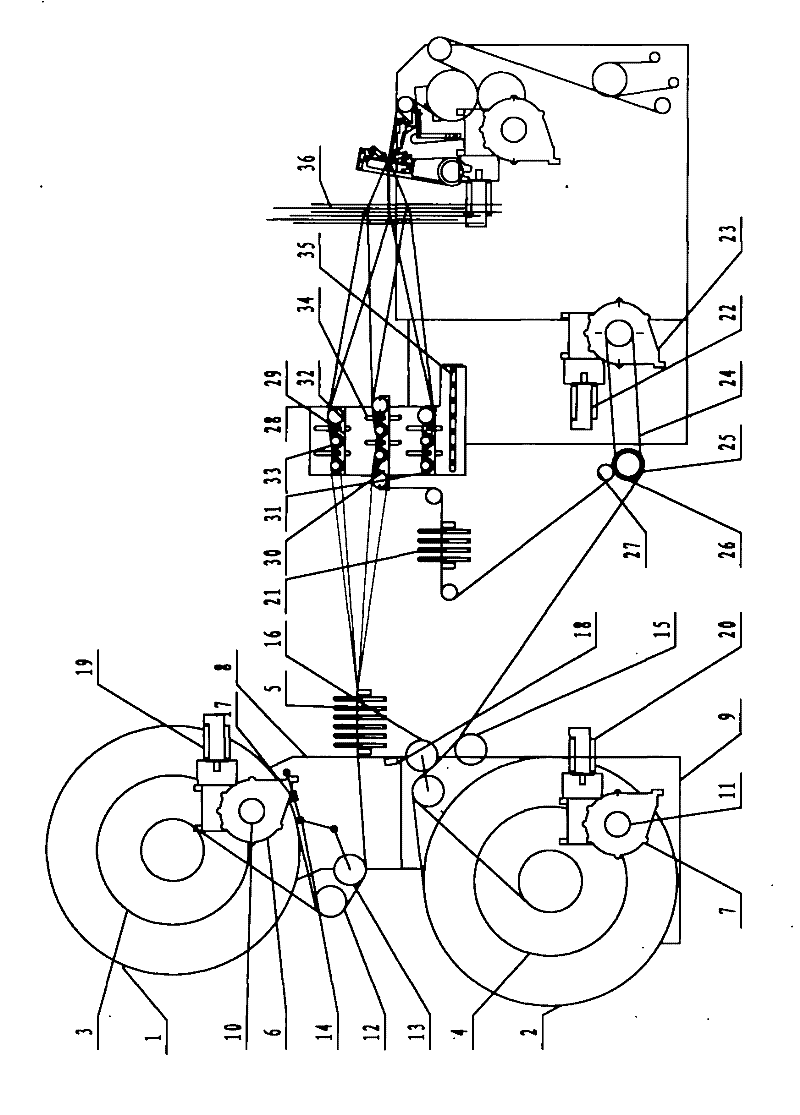

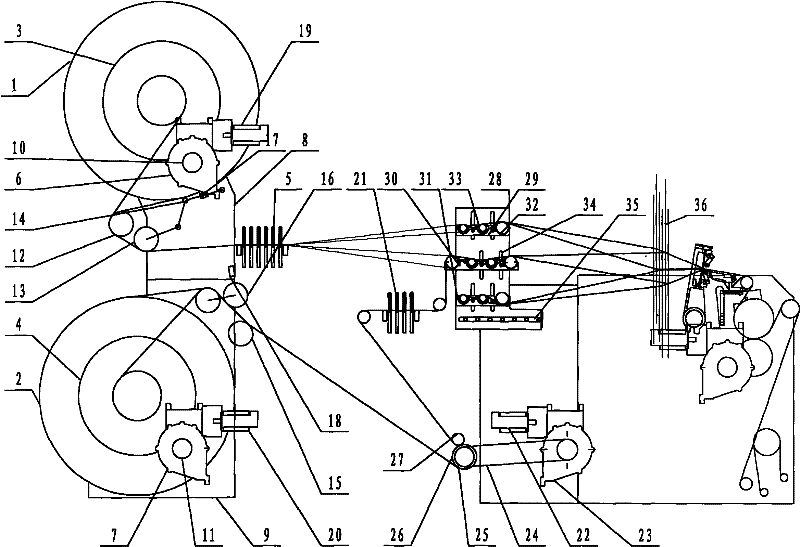

[0024] The present invention is described in detail below in conjunction with involved device and using method thereof:

[0025] As shown in the figure, the independent electronic warp let-off device used in the method for efficiently weaving double-layer flannelette according to the present invention includes a ground warp disc 1, a pile warp disc 2, a ground warp side disc gear 3, and a pile warp side disc Gear 4, ground via stop frame 5, ground via electronic gearbox 6, velvet via electronic gearbox 7, upper wall panel 8, lower wall panel 9, ground via electronic gearbox output drive gear 10, velvet via electronic gearbox output Transmission gear 11, ground warp guide roller 12, ground warp tension roller 13, ground warp tension rod 14, pile warp guide roller 15, pile warp tension roller 16, ground warp tension sensor 17, pile warp position sensor 18, ground warp Servo motor 19, velvet warp servo motor 20, velvet warp stop frame 21, servo motor 22, gearbox 23, timing belt 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com