Portable fiber heating test device and method

A test device and portable technology, applied in the field of portable optical fiber heating test devices, can solve the problems of inconsistency in temperature, fast heat dissipation of hot water, large measurement error, etc., and achieve the effects of convenient operation, convenient heating, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

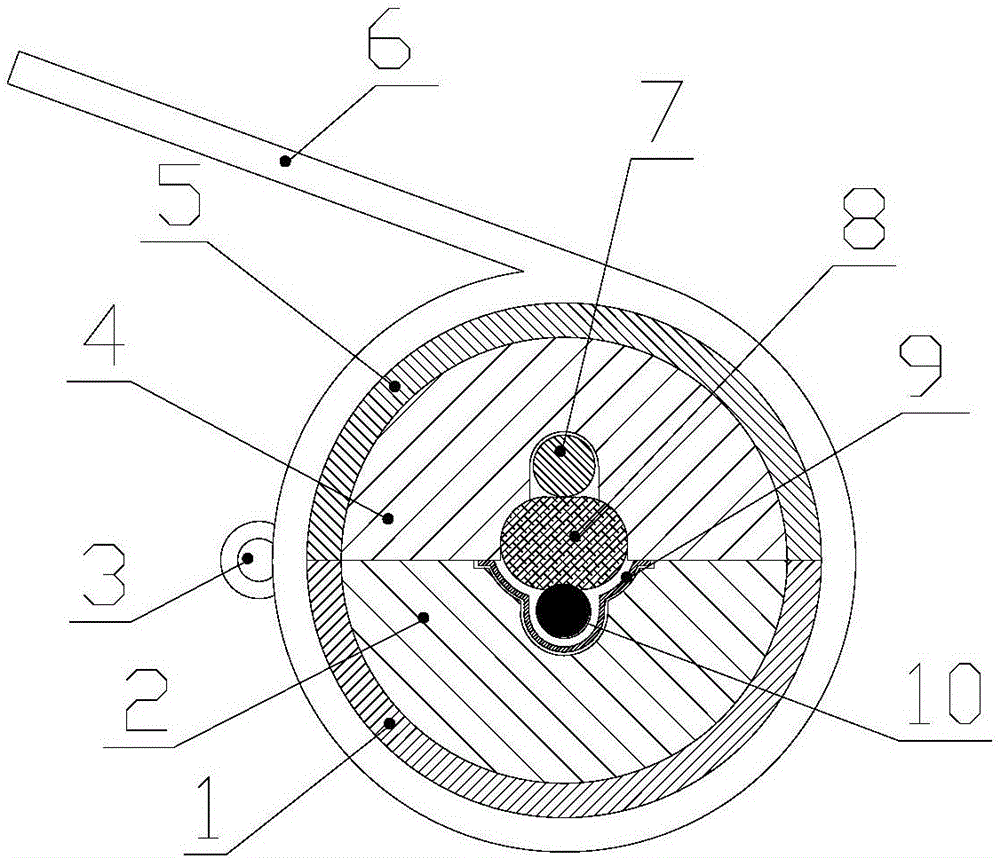

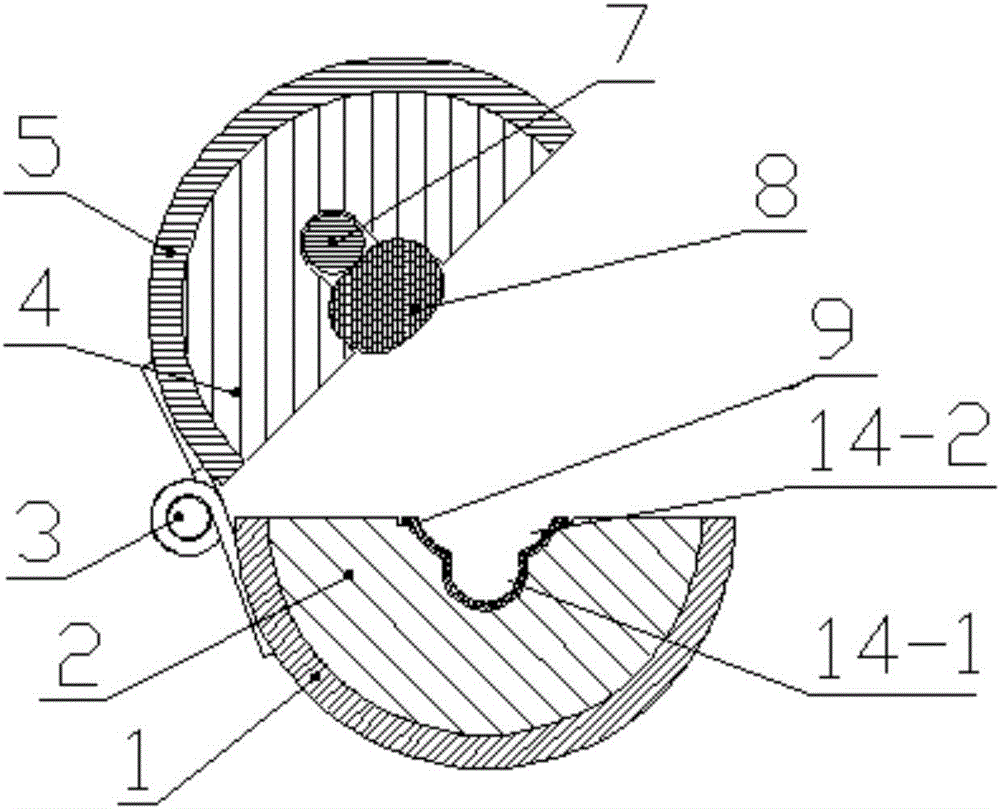

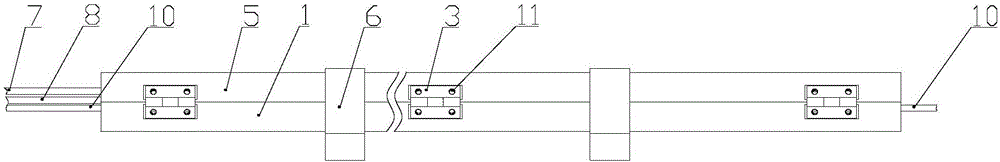

[0035] Embodiment: a kind of portable optical fiber heating test device, its structure is as follows Figure 1-4 As shown, it includes two parts: a portable case 12 and a heating rod 13. The portable case 12 contains common components such as batteries, inverters, chargers, and temperature controllers, and has temperature indication, voltage indication screens, and related cable interfaces. The internal structure of the box need not be described in detail here.

[0036] The heating rod 13 is composed of a shell, a heat insulating sheet and a heat conducting sheet 9 . The shell is divided into upper and lower parts: an upper housing 5 and a lower housing 1 , and the heat insulating sheet is also divided into upper and lower parts: an upper insulating sheet 4 and a lower insulating sheet 2 . The upper casing 5 and the lower casing 1 are connected by a hinge 3, which is convenient for opening without separation. The hinge 3 is installed on the upper casing 5 and the lower casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com