Enhancement fan impellor

A pulse electroplating and process technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of blade height limitation, affecting the service life, destroying the surface of the impeller, etc., to increase the air volume and pressure, prolong the service life, The effect of increased impeller height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

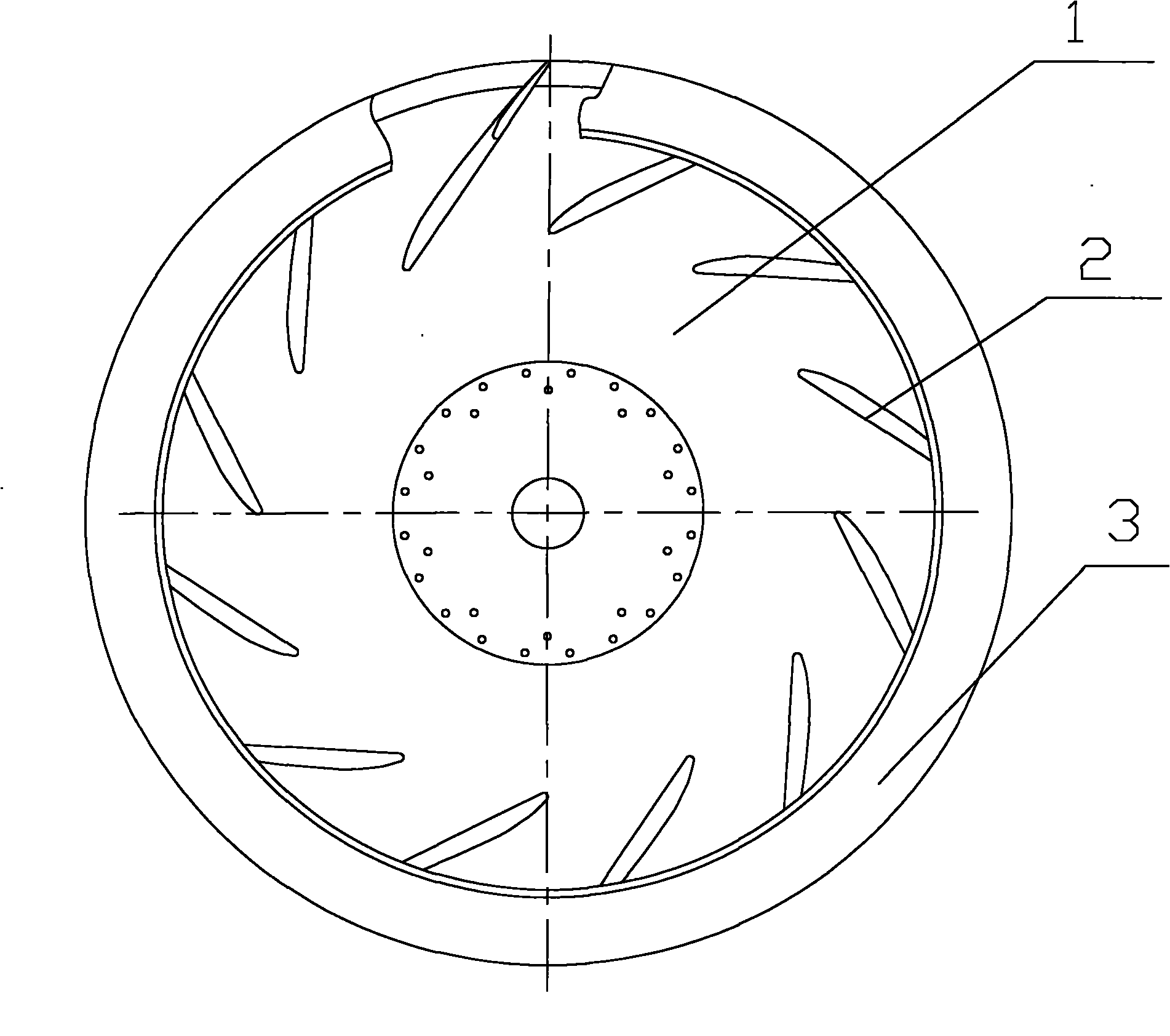

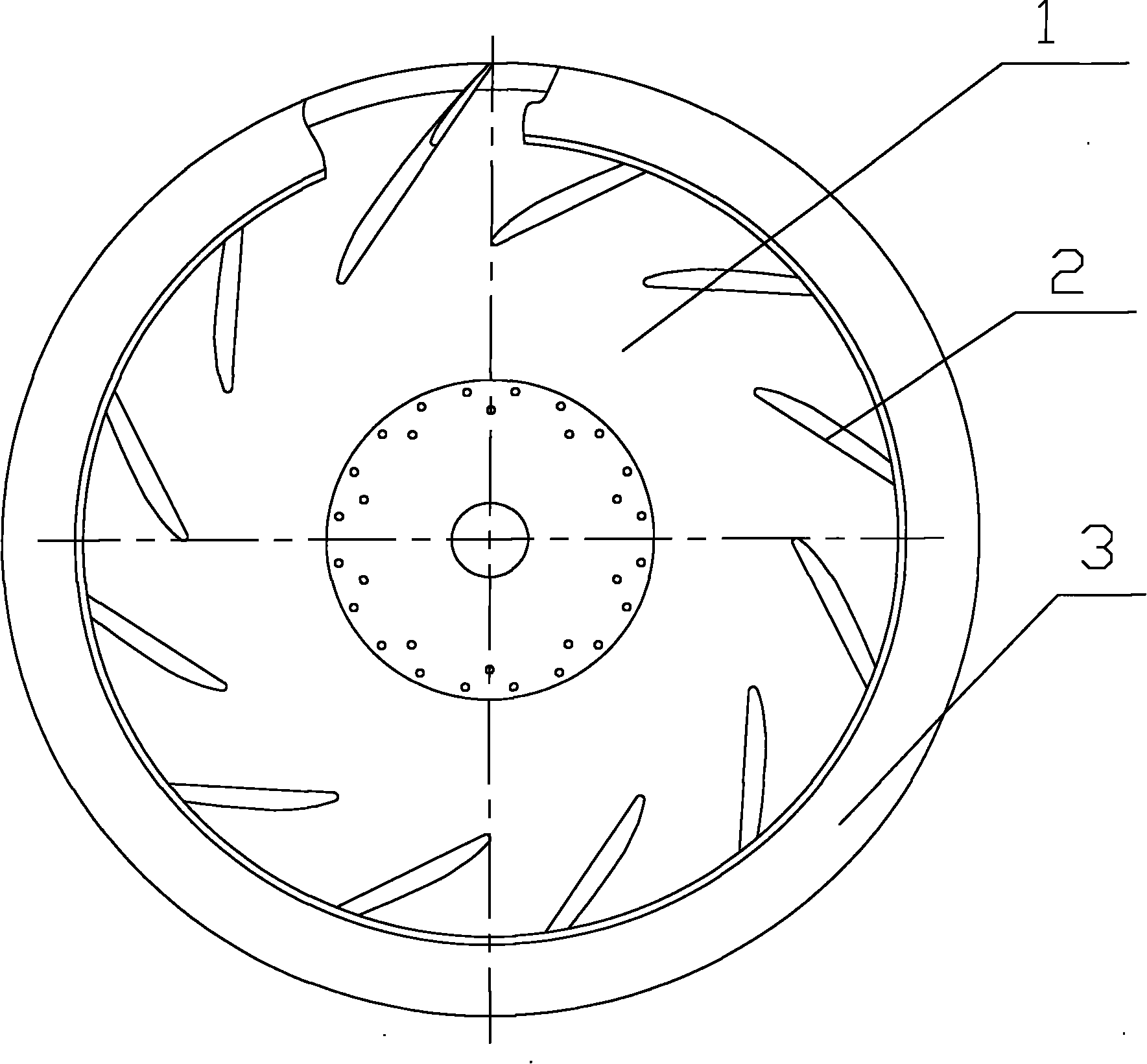

[0008] Such as figure 1 As shown, an enhanced fan impeller includes an impeller 1. Several blades 1 are arranged on the impeller 1. The thickness of each impeller 1 decreases from the middle to both ends. The impeller 1 on one side of the blade 2 is connected to the impeller front disk 3 , the front disc 3 of the impeller makes an arc transition towards the blade 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com